Automatic backlight component detecting, labeling and film sticking production line and method

An automatic detection and production line technology, used in the production line of labeling and filming, automatic detection of backlight components, labeling and filming fields, and can solve problems such as restricting the output efficiency of backlight components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

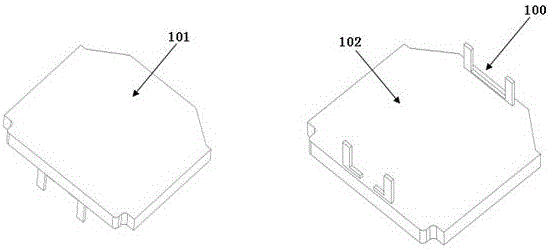

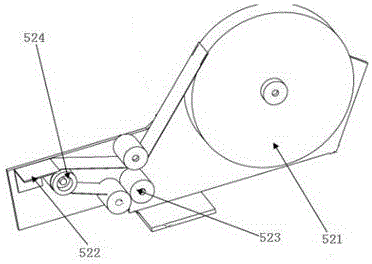

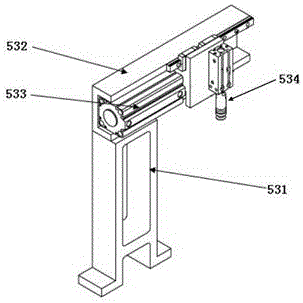

[0062] Combine below Figure 2 to Figure 12 Embodiments of the present invention are described in detail.

[0063] Such as figure 2As shown, the production line for automatic detection, labeling and filming of backlight components is automatically controlled by a software-driven system, including a horizontally arranged workbench 1, which is equipped with a conveying mechanism 9 for feeding and discharging backlight components. Power-on detection of backlight components and transmission of detection results to the power-on detection table 2 in the software-driven system, rotary disc 3 for labeling and filming backlight components, moving backlight components to the power-on detection table and rotary circle The feeding device 4 on the disk, the position detection camera 6 for detecting the position of the backlight component on the rotary disk and transmitting the detection result to the software drive system, the film sticking device 7 for sticking the film on the backlight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com