A sheet drawing machine

A wire drawing machine and plate technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of high risk of operation, difficulty in replacement, and time-consuming readjustment, etc., and achieve the effect of high-efficiency friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

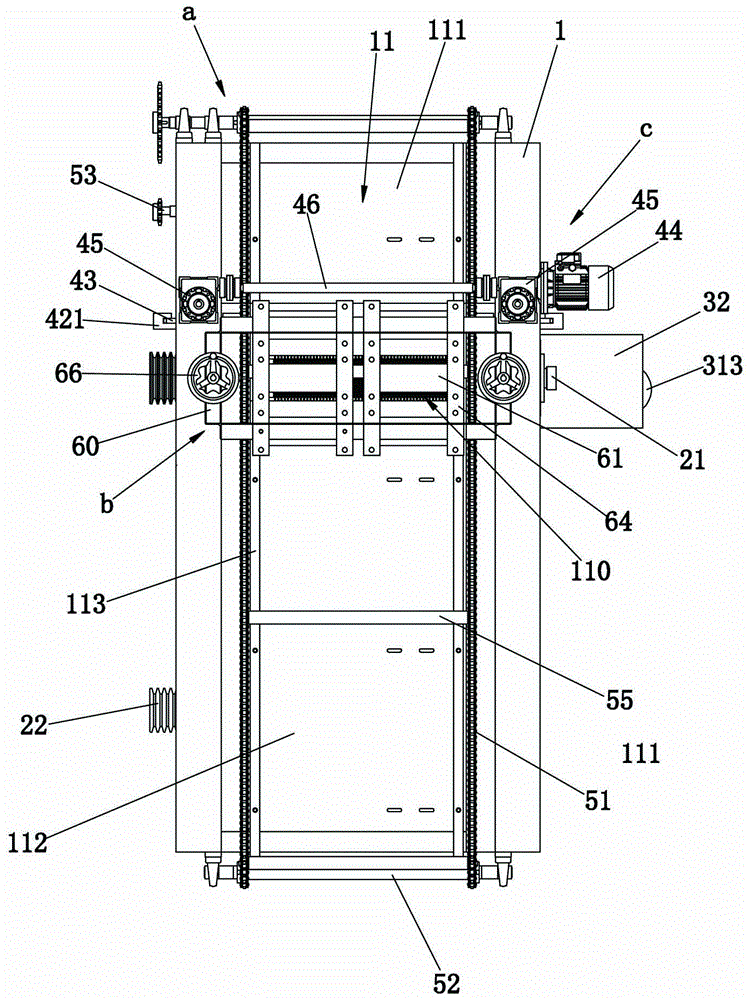

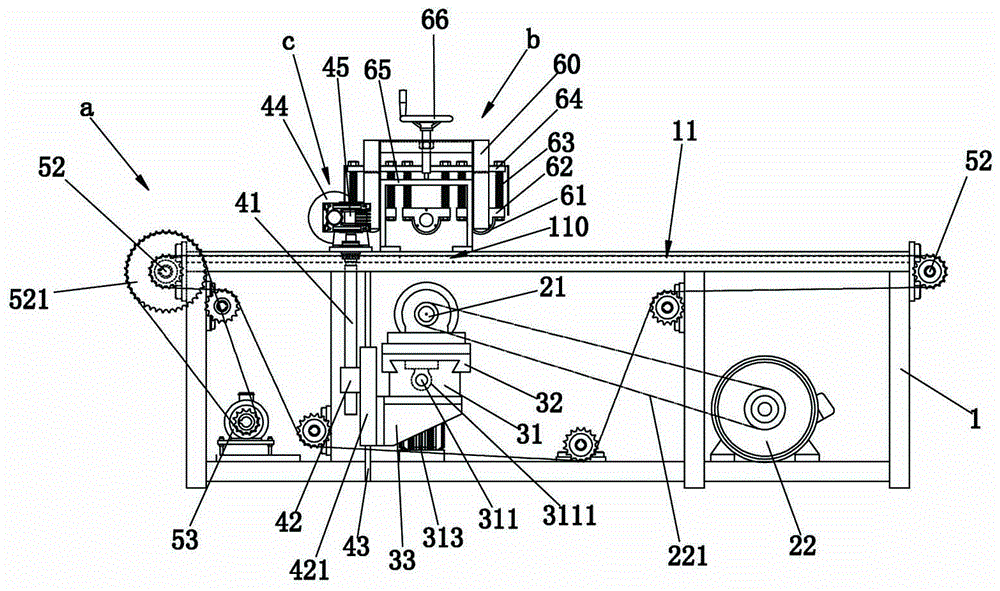

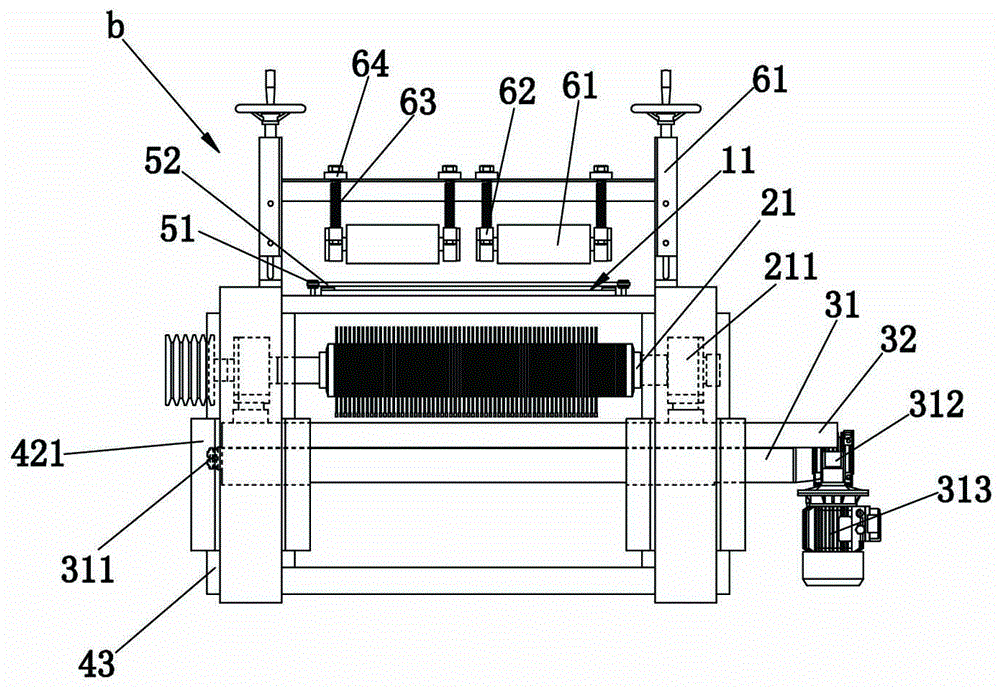

[0023] refer to figure 1 , figure 2 and image 3 , a plate wire drawing machine, including a frame 1, the upper end surface of the frame 1 is provided with a working table 11 and a conveying mechanism a for moving the processed plate on the working table 11. The frame 1 is provided with a main shaft 21 and a main shaft motor 22 on which a saw blade is housed under the work surface 11 . The working surface 11 is provided with a grooving slot 110 directly above the main shaft 21 for the saw blade to extend into. The frame 1 is provided with a floating pressing mechanism b above the planing slot 110 . The plate wire drawing machine also includes a lower rail 31 and an upper rail 32, the main shaft 21 is detachably erected horizontally on the lower rail 31 through the mounting seat 211, the lower rail 31 is horizontally arranged on the frame 1 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com