Butt-jointing and assembly welding method of cone cylinders

A cone and assembly welding technology, which is applied to welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of unstable quality, large energy consumption, low efficiency, etc., to reduce the difficulty of operation, improve the precision of butt joint, and improve the quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

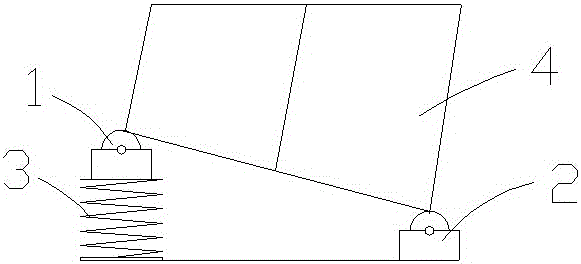

[0021] like figure 1 As shown, the present invention provides a method for butt welding of cones, including step 1: placing a group of roller frames A1 on the lifting platform 3 .

[0022] It also includes step 2: placing another set of roller frames B2 on the ground, and using them in pairs with the roller frame A1 placed on the lifting platform 3 .

[0023] It also includes step 3: butt jointing, first place one section of the adjacent cones 4 for docking positioning spot welding, then hang the cones 4 together on the roller frame, and place the small diameter end of the cones 4 on the roller frame A1 on the lifting platform 3 Place the large-diameter end of the cone 4 on the roller frame B2 on the ground.

[0024] Step 4 is also included: rotating the section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com