Fetching and conveying tool based on workpiece dimensions for stamping piece

A technology for stamping parts and workpieces, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., and can solve problems such as bad influence, too small shape of the workpiece, special problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

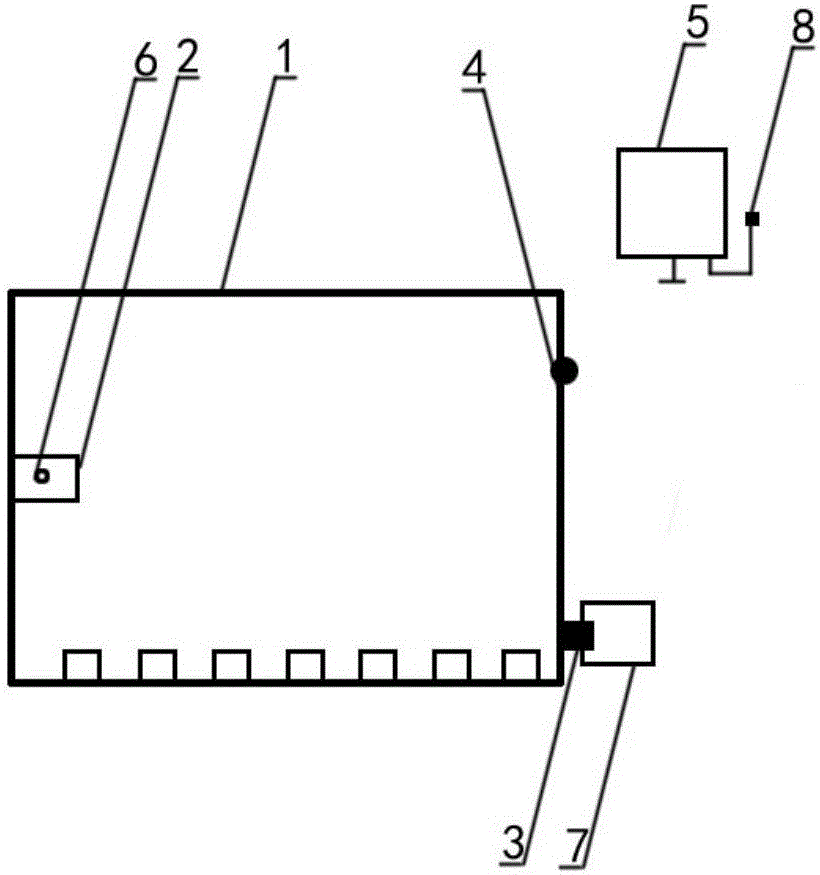

[0012] Embodiment: as shown in the accompanying drawing. A tooling for picking and delivering stamping parts based on workpiece size, comprising a body (1), on which a workpiece sensing module (2), a pyroelectric infrared sensing module (3), an information receiving module (4), The management module (5), during operation, the workpiece sensing module (2) senses the size and value of the workpiece, the pyroelectric infrared sensing module (3) senses the distance between the person and the workpiece, and the information receiving module (4) receives the information Transfer to the management module (5) for processing.

[0013] A stamping part pick-up and delivery tool based on the workpiece size, a scale adjustment module (6) is set on the workpiece induction module (2), and workpieces within a certain size range are set not to be directly picked up and sent according to operation requirements.

[0014] A stamping part is based on workpiece size pick-up and delivery tooling, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com