Gas purifier and its working method

A technology of gas purifier and working method, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle filtration, etc. It can solve the problems of affecting filtration performance, filter cotton or activated carbon pore clogging, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

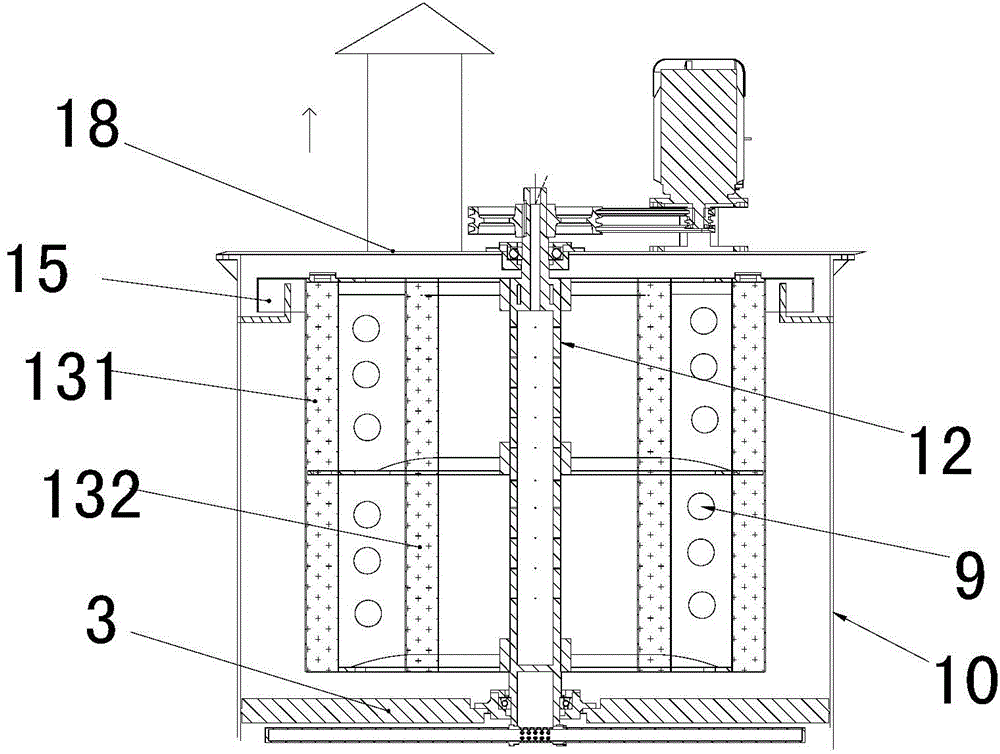

[0030] On the basis of Embodiment 1, there are the following modifications in this embodiment:

[0031] Such as figure 2 , the filter cartridge 13 includes a plurality of cylinders with the same central axis and arranged alternately, only the outermost cylinder 131 and the top inner wall of the housing 10 are rotated and sealed by the sealing mechanism 15, and the walls of each cylinder The diameter of the micropores on the top gradually becomes smaller in the direction of gas travel; a coiled high-pressure water spray pipe 9 is provided in the gap between adjacent cylinders, which is used to spray water on the inner wall of the corresponding cylinder; The bottom end is closed, and the top of the adjacent cylinder is sealed and connected; only the top port of the innermost cylinder 132 communicates with the exhaust port on the top wall of the housing 10; the coiled high-pressure water spray pipe 9 is connected to all The water inlet of the hollow shaft 12 is connected.

Embodiment 3

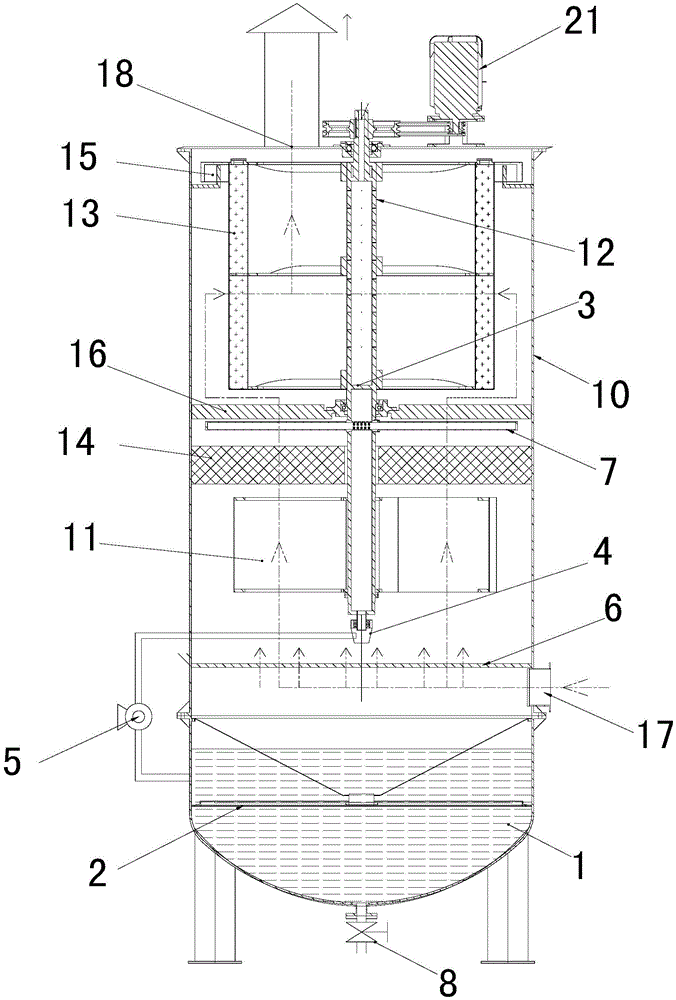

[0033] A working method of the gas purifier described in the above embodiment 1 or 2, comprising: the gas to be purified is input into the housing 10 from the air inlet, enters the filter cartridge radially from the outside of the filter cartridge 13 under the action of air pressure, Part of the particles or oil in the gas is adhered to the outer wall of the filter cartridge 13, and the water spray hole on the hollow shaft sprays water to the inner wall of the filter cartridge at regular intervals or all the time;

[0034] At the same time, the hollow shaft drives the filter cartridge to rotate, so that the water in the filter cartridge passes through the micropores on the wall of the filter cartridge under centrifugal force, reaches the outer wall of the filter cartridge, and scours the outer wall of the filter cartridge particulate matter on.

[0035] The water in the upper box at the bottom of the housing 10 is sent to the shower 7 in the housing 10 through the water pump 5...

Embodiment 4

[0040] On the basis of the above-mentioned embodiment 1 or 2 or 3, the working method of the gas purifier specifically includes: the gas input into the casing 10 from the air inlet passes through the gas equalizing plate 6, and goes upward evenly; Part of the particulate matter is mixed with the mist generated by the filter screen 11, and falls to the water storage tank 1 at the bottom of the housing 10 under gravity; another part of the particulate matter in the gas is filtered upward through the primary filter material layer 14, and the gas continues upward. Under the action, it enters the filter cartridge radially from the outside of the filter cartridge 13, and the remaining particles or oil in the gas are adhered to the outer wall of the filter cartridge 13; the water spray hole on the hollow shaft 12 sprays water to the inner wall of the filter cartridge ;

[0041] At the same time, the hollow shaft drives the filter cartridge to rotate, so that the water in the filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com