Vacuum freeze-dried green coffee beans and processing method thereof

A vacuum freeze-drying and processing method technology, which is applied in green coffee processing, etc., can solve the problems of large external environment influence, affecting commodity value, and long drying time, so as to avoid excessive loss, shorten processing time, and improve processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

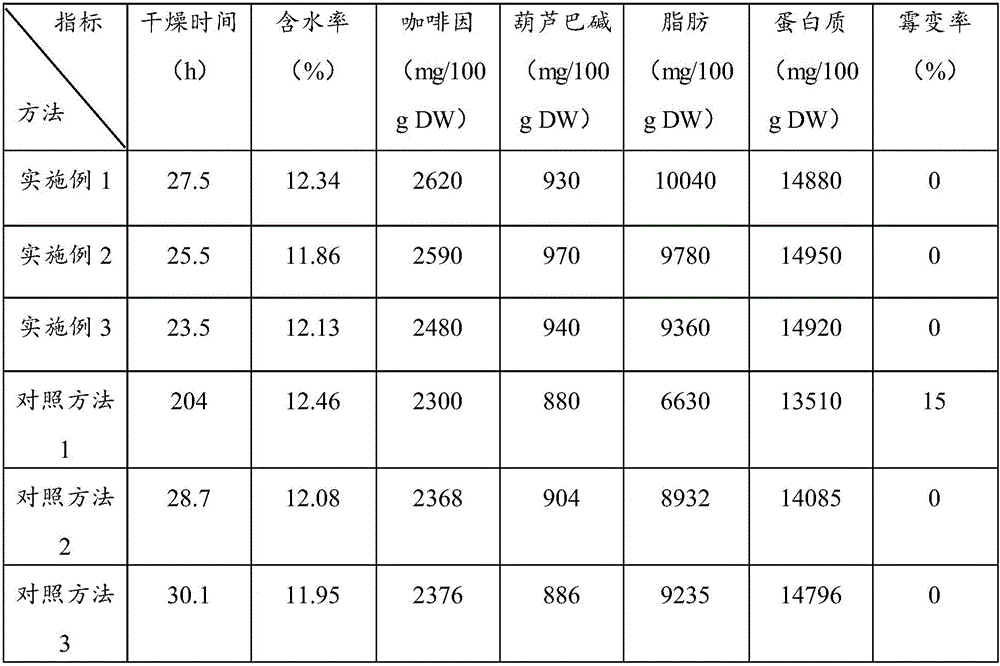

Examples

Embodiment 1

[0026] Embodiment 1: vacuum freeze-dried green coffee bean processing method of the present invention

[0027] Siphon flotation, pour the picked fresh Robusta coffee fruit into the siphon tank, add clean water, and stir to remove floating fruit, branches, leaves and other sundries, and at the same time remove the dust and sand on the surface of the fresh coffee fruit;

[0028] Drain the water and dry the plump fresh coffee cherries separated by siphon flotation, so as to remove the residual moisture on the surface of the coffee cherries as soon as possible.

[0029] Put the drained fresh coffee cherries into a freezer at -40°C, and freeze them for 4 hours until the center temperature of the fresh coffee cherries is -35°C to -30°C, and then keep them for another 1 to 2 hours, and the pre-freezing is over.

[0030] The pre-frozen fresh coffee fruit is quickly transferred from the freezer to the working chamber of the vacuum freeze dryer, the vacuum degree is controlled at 50Pa, ...

Embodiment 2

[0032] Embodiment 2: vacuum freeze-drying green coffee bean processing method of the present invention

[0033] Siphon flotation, pour the picked fresh Robusta coffee fruit into the siphon tank, add clean water, and stir to remove floating fruit, branches, leaves and other sundries, and at the same time remove the dust and sand on the surface of the fresh coffee fruit;

[0034] Drain the water and dry the plump fresh coffee cherries separated by siphon flotation, so as to remove the residual moisture on the surface of the coffee cherries as soon as possible.

[0035] Put the drained fresh coffee cherries into a freezer at -35°C, freeze for 6 hours, freeze until the temperature of the center of the fresh coffee cherries is -35°C to -30°C, and then maintain it for 1 to 2 hours, and the pre-freezing is over.

[0036] The pre-frozen fresh coffee fruit is quickly transferred from the freezer to the working chamber of the vacuum freeze dryer. The vacuum degree is controlled at 40Pa,...

Embodiment 3

[0038] Embodiment 3: vacuum freeze-drying green coffee bean processing method of the present invention

[0039] Siphon flotation, pour the picked fresh Robusta coffee fruit into the siphon tank, add clean water, and stir to remove floating fruit, branches, leaves and other sundries, and at the same time remove the dust and sand on the surface of the fresh coffee fruit;

[0040] Drain the water and dry the plump fresh coffee cherries separated by siphon flotation, so as to remove the residual moisture on the surface of the coffee cherries as soon as possible.

[0041] Put the drained fresh coffee cherries into a freezer at -30°C, freeze them for 7 hours, freeze until the center temperature of the coffee cherries is -35°C to -30°C, and then maintain them for 1 to 2 hours, and the pre-freezing is over.

[0042] The pre-frozen fresh coffee fruit is quickly transferred from the freezer to the working chamber of the vacuum freeze dryer. The vacuum degree is controlled at 60Pa, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com