Winding device for winding a web-shaped material and method for changing a spool in a winding device

A winding device and strip-shaped technology, which is applied to the winding device for winding strip-shaped materials and the field of replacing the package in the winding device, can solve the problems of no longer having a winding effect, and achieve simple design, Reliable drive, slip-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

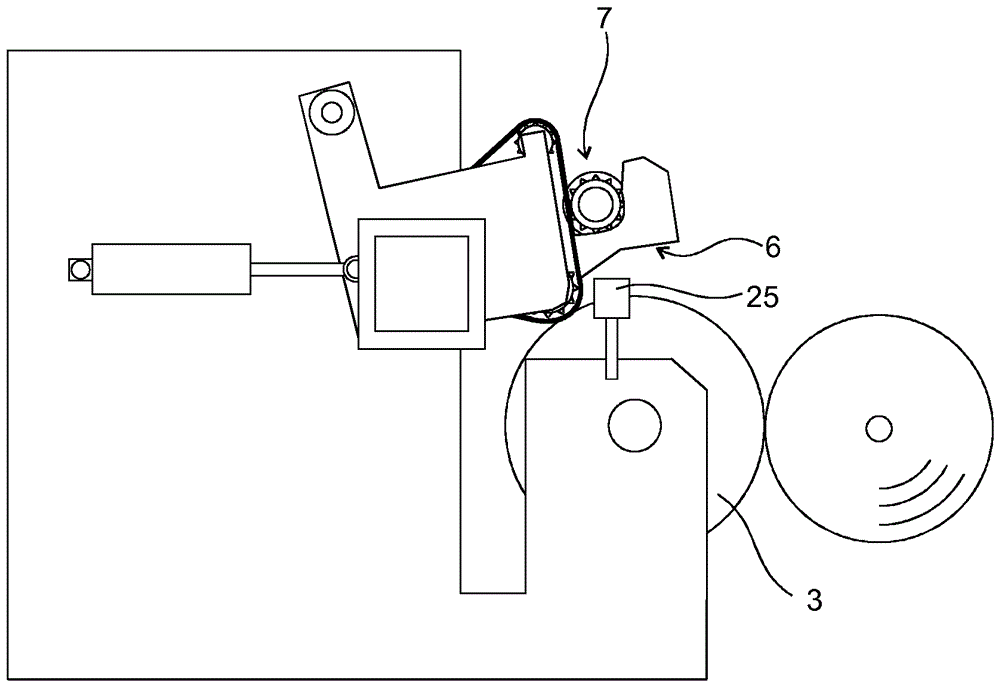

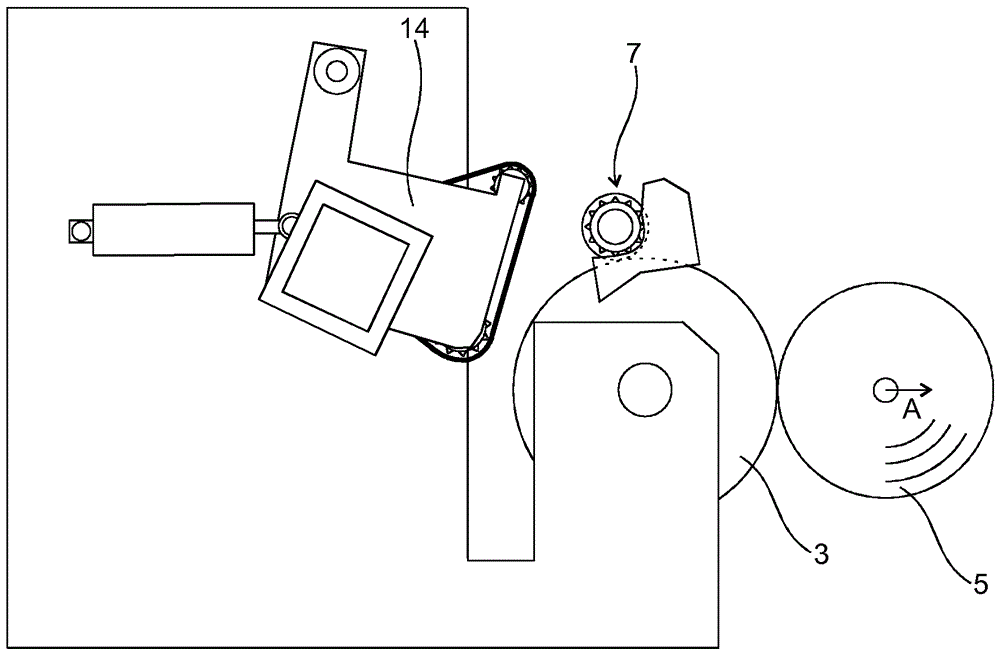

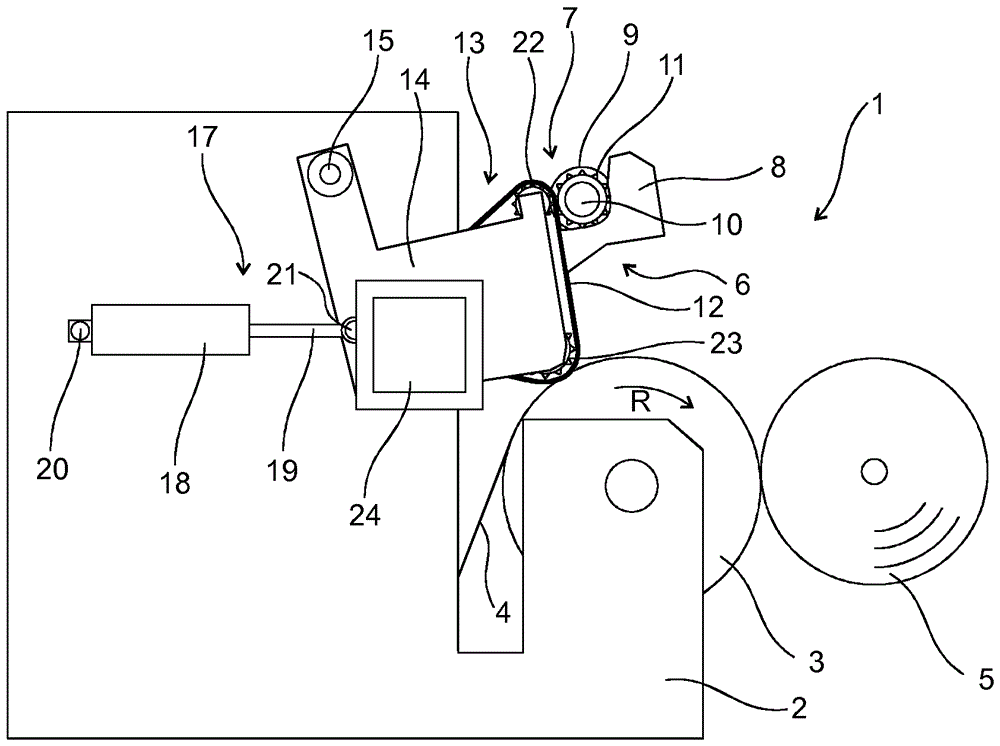

[0030] Figure 1-3 Each shows a schematic side view of a winding device 1 according to the invention, comprising a frame 2 and a contact roller 3 rotatably mounted in the frame, the contact roller rotating in the direction of rotation R. The strip material 4 wound up on the package 5 is supplied by the contact roller 3 .

[0031] The displacement device 6 for guiding the empty package 7 to the contact roller 3 is preferably linearly movable relative to the machine frame and relative to the contact roller in a manner not shown in detail. exist figure 1 In , the mobile device 6 is in its initial position. The package 7 is supplied from a package store (not shown) and now lies flat on the support mechanism 8 .

[0032] The package 7 comprises a winding bobbin 9 such as a paper bobbin, a journal 10 and a gear 11 arranged on the journal.

[0033] exist figure 1 , the gear 11 meshes with a toothed belt 12 of a device 13 for rotationally driving the empty package. The toothed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com