Manufacturing method of flexible substrate

A technology of flexible substrates and manufacturing methods, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of flexible device corrosion, flexible substrate damage, excessive temperature, etc., and achieve reduced production costs, efficient stripping, and improved yields Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

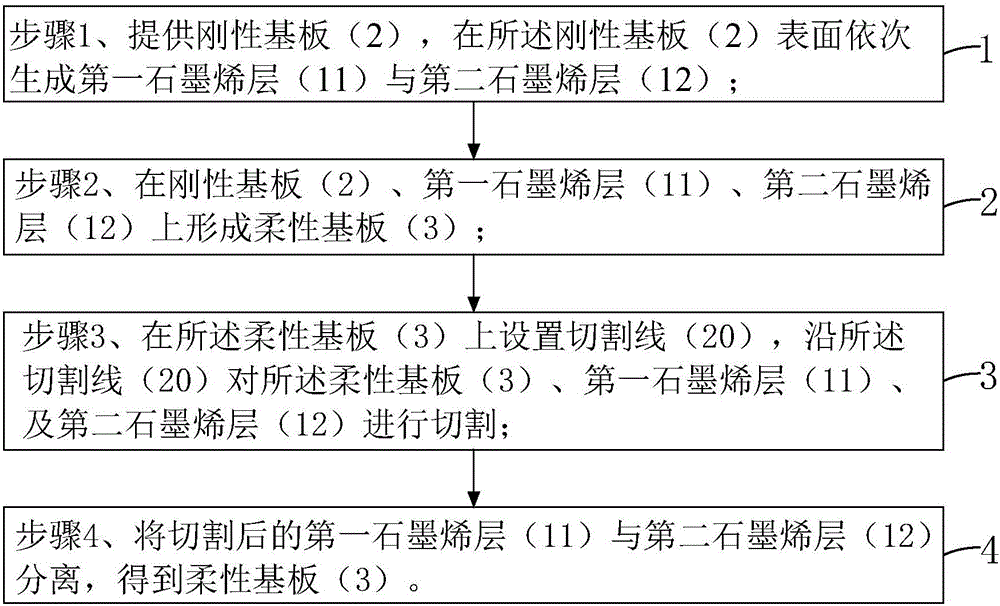

[0033] see figure 1 , the present invention provides a method for manufacturing a flexible substrate, comprising the following steps:

[0034] Step 1, such as Figure 2-4 As shown, a rigid substrate 2 is provided, and a first graphene layer 11 and a second graphene layer 12 are sequentially formed on the surface of the rigid substrate 2 .

[0035] The specific implementation of described step 1 comprises the following steps:

[0036] Step 11, such as figure 2 As shown, a substrate 1 is provided, and a first graphene layer 11 is formed on the surface of the substrate 1 .

[0037] Specifically, the material of the substrate 1 is metal; the step 11 adopts a chemical vapor deposition (Chemical Vapor Deposition, CVD) method under high temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com