Method for detecting decontamination efficiency of feather down fine washing reuse water

A detection method and water reuse technology, which is applied in the field of fine down washing, can solve the problems of increased production costs, long test time, and complicated test operations, and achieve the effects of improving test accuracy, reducing test procedures, and reducing operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

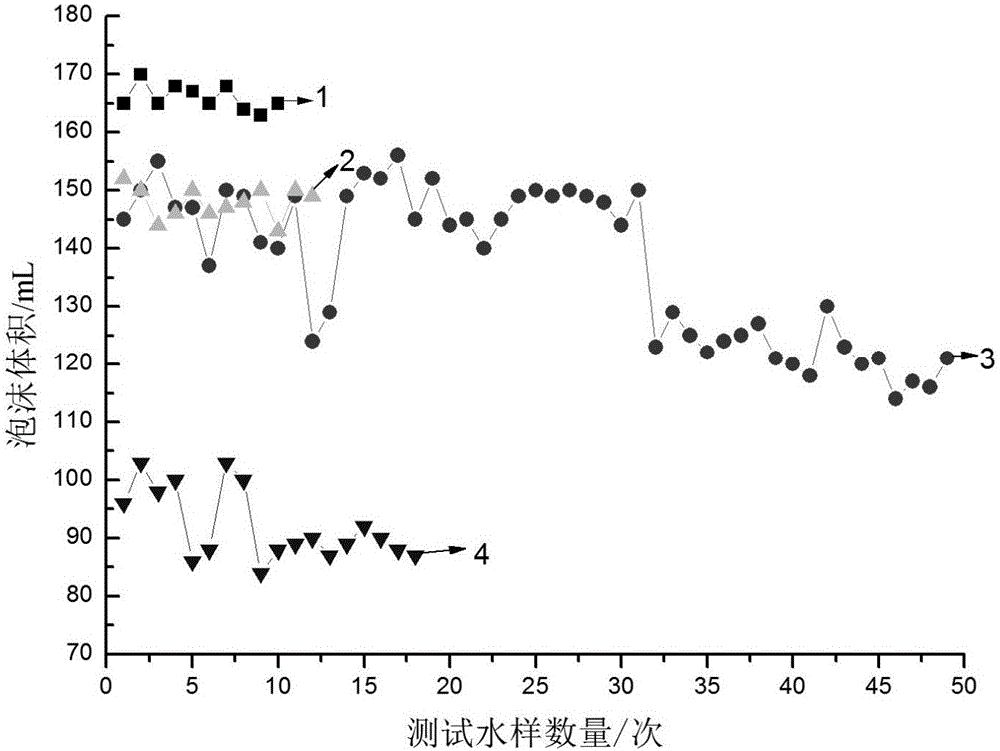

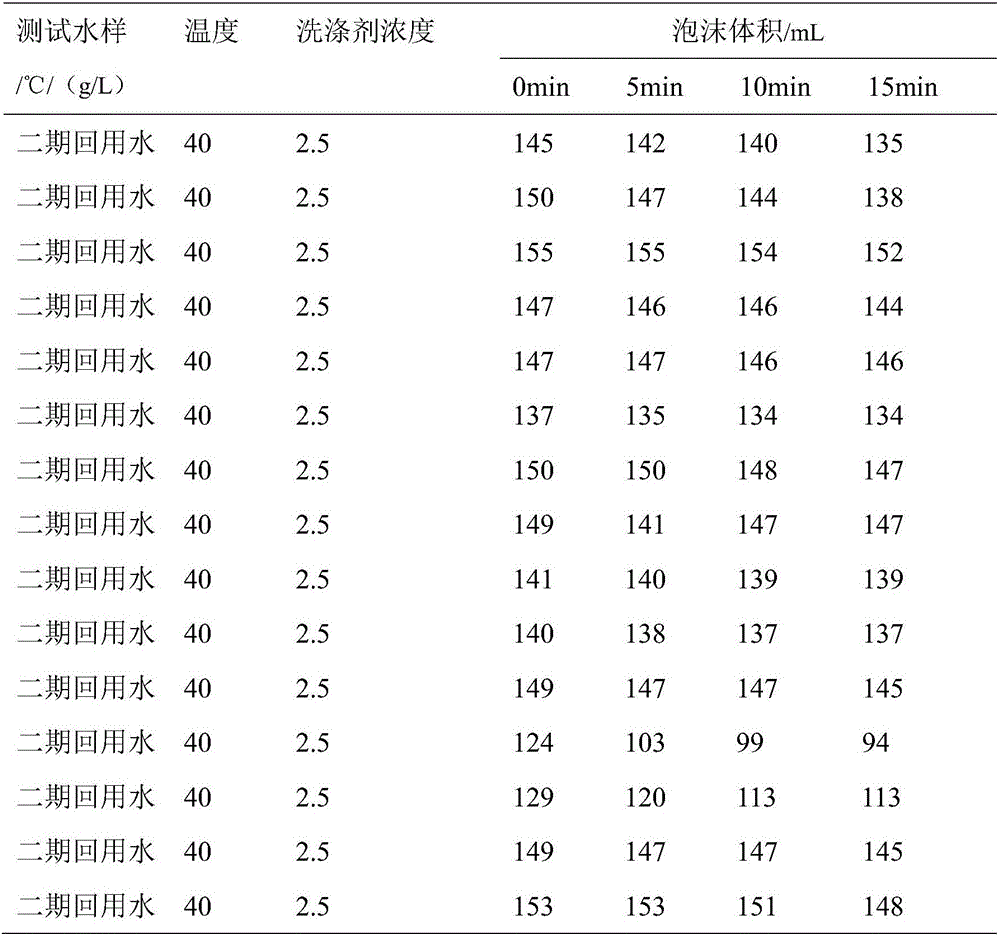

[0021] Example 1

[0022] A method for detecting the decontamination efficiency of feather velvet fine washing water, including the following steps:

[0023] (1) The first-stage treatment of feather down essence washing and recycling water, the second-stage treatment of feather down essence washing and recycling water, down essence washing drainage and tap water sampling 1L, adding 2.5g compound detergent; stirring well, putting it in the water bath slowly Heat to 40°C to obtain the solution to be tested, set aside.

[0024] The composition of the composite detergent: anionic surfactant, nonionic surfactant, and foam stabilizer in a mass ratio of 10:2:0.5.

[0025] (2) Use a Roche foaming instrument to test the foaming performance of the solution to be tested; test the maximum foam volume and foam stability value (read the foam height after the foam is stable for 5 minutes) three times each, and take the average value; specific operation In order to stabilize the water temperature in...

Example Embodiment

[0046] Example 2

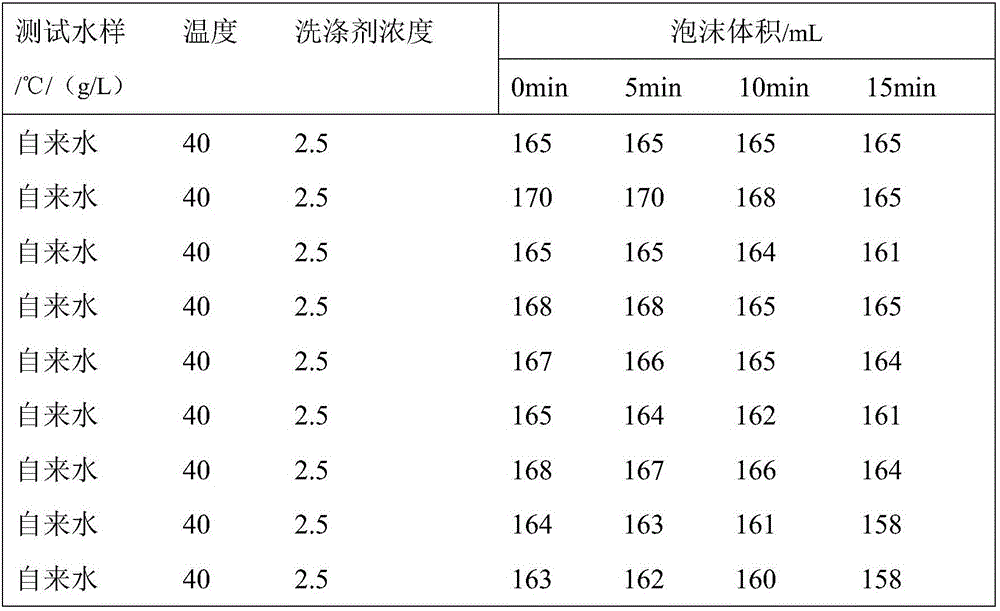

[0047] The test sample is tap water, and the steps of Example 1 are repeated to test the foaming stability of the composite detergent.

[0048] Table 5 Foaming stability test of composite detergent (unit: ml)

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com