Method for detecting thickness of steel tape on line

A steel strip and thickness detection technology, which is applied to measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of inconvenient detection, error-prone, length reduction, etc., to avoid inaccurate measurement and prevent the threat of electric shock , The effect of safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

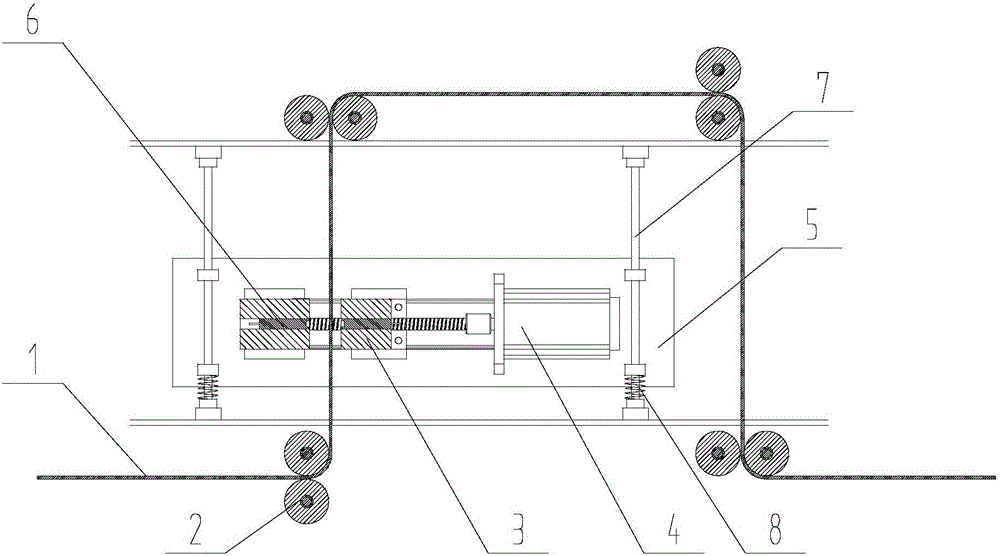

[0027] Refer to figure 1 As shown, a method for online detection of the thickness of a steel belt of the present invention first uses several pairs of transmission roller sets 2 to change the transmission direction of the steel belt 1, wherein two pairs of transmission roller sets 2 are arranged adjacently and one pair of transmission The roller set is located directly above the other pair of drive roller sets, so that the steel belt 1 has a section of vertical upward transmission; two compression blocks 3 are provided on the left and right sides of the steel belt 1 that is transmitted vertically upwards, two compression blocks 3 Driven by the same driving device 4, the driving device 4 drives the two compression blocks 3 to clamp and separate each other; the two compression blocks 3 and the driving device 4 are fixed on the movable plate 5 as a whole, and the movable plate 5 can Move freely in the vertical direction. When the steel belt 1 is clamped by the two compression bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com