Upper-screwing lower-locking automatic insertion rod adjustable connection component

An adjustable, connecting piece technology, applied in the connection of rods, connecting members, sheet pile walls, etc., can solve the problems of work efficiency, inconvenient rotation, small space, etc., to improve work efficiency, firm connection, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

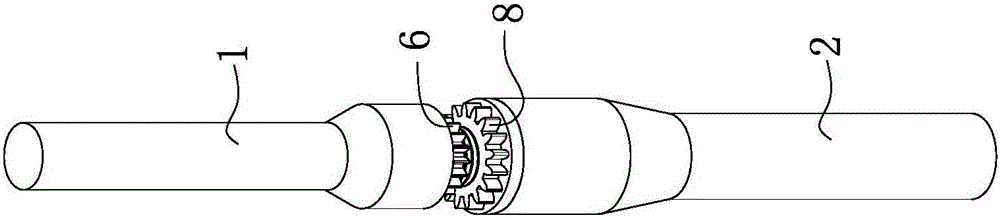

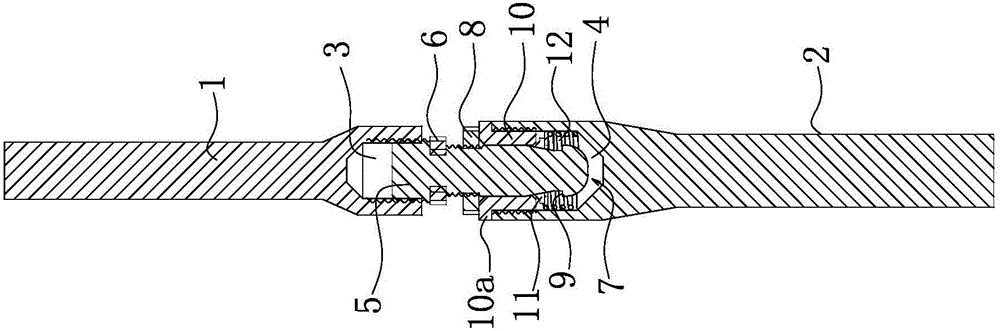

[0028] Such as figure 1 and figure 2 and image 3 As shown, a screw-on-down-lock automatic plunger adjustable connector includes an upper connecting rod 1 and a lower connecting rod 2, and the ends of the upper connecting rod 1 and the lower connecting rod 2 respectively have an upper connecting cavity 3 and The lower connection cavity 4, preferably, the outer walls of the upper connection cavity 3 and the lower connection cavity 4 are inflated, which is convenient for manufacture and connection. The upper connection cavity 3 and the lower connection cavity 4 have internal threads, and the upper connection rod 1 The inner screw is connected with a plugging rod 5, and the inner screw of the lower connecting rod 2 is connected with a clamping mechanism 7. The outer wall of the plugging rod 5 has a ring gear 6 integrally formed with the plugging rod 5. When the plugging rod 5 is inserted into When entering the clamping mechanism 7 , rotating the ring gear 6 can adjust the posi...

Embodiment 2

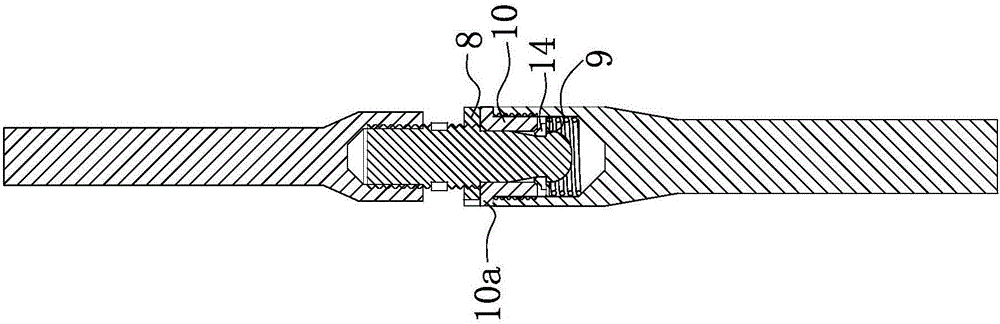

[0037] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as Figure 4 and Figure 5 As shown, the end of the insertion rod 5 has a step-shaped clamping platform 9, and the clamping mechanism 7 includes a spring assembly 14 screwed to the lower connection chamber 4. When the insertion rod 5 is inserted into the spring assembly 14 At this time, rotating the ring gear 6 can make the card table 9 close to the spring assembly 14 and make the card table 9 and the end of the spring assembly 14 form a snap fit. Since the structure of the shrapnel assembly 14 is relatively simple, it is easy to assemble and use.

[0038] combine Figure 7 As shown, the shrapnel assembly 14 includes a shrapnel threaded portion 15 that is threadedly engaged with the lower connection chamber 4 , and the end of the shrapnel threaded portion 15 is provided with a number of springs evenly distributed along the axial direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com