A method of caving top coal in weakened hard coal seams based on carbon dioxide blasting

A carbon dioxide and top coal caving technology, which is applied in earth-moving drilling, discharging machinery, surface mining, etc., can solve the problems of increasing the amount of roadway excavation, large investment in the working face, and excessive plugging of blast holes, and achieves significant economic benefits. , saving investment, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

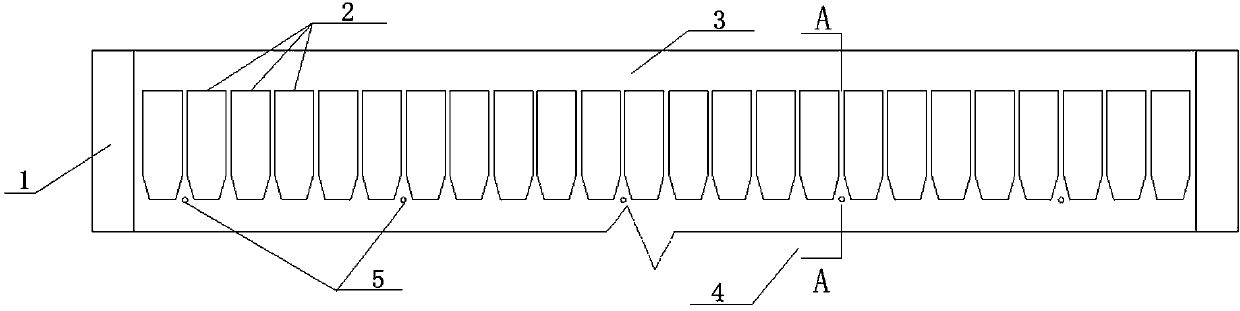

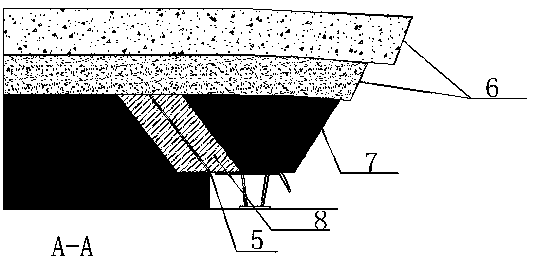

[0021] In this embodiment, the method for caving top coal in weakened hard coal seams based on carbon dioxide blasting, the thickness of the coal seam is 12m, and the comprehensive mechanized top coal caving method is used for mining, the mining height is 3m, and the coal caving height is 7m. Such as figure 1 , figure 2 shown, follow the steps below:

[0022] (1) During the coal seam recovery process, between the top beams of the hydraulic supports 2 and near the roof of the coal wall, every 5 hydraulic supports are set to penetrate the top coal 7 coal body to reach the coal seam roof 6 Borehole 5, drill hole 5 It has a certain inclination angle α 45° with the coal seam roof 6, and the length L of the borehole 5 is 10m;

[0023] (2) Put the carbon dioxide cracker in the drill hole 5, insert it to the bottom of the hole, seal the hole with a bag type or rubber sealer, the length of the hole is 1.5m, and set the connecting wire of the flystop, use the explosive The heater is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com