A method for mining hanging side mines by partition under an open-pit transportation system

A technology of transportation system and partition mining, which is applied in underground mining, ground mining, special mining, etc., to achieve the effect of improving filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

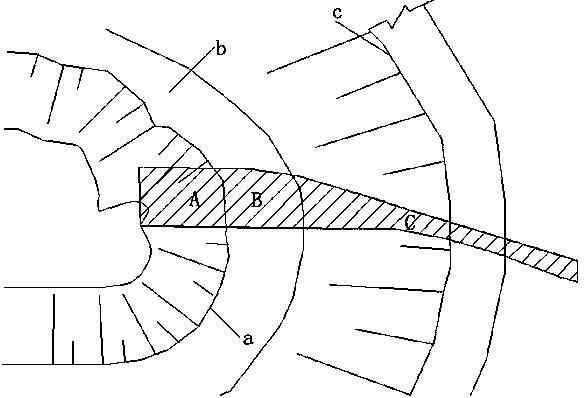

[0032] Such as figure 1 Shown is the plan view of the hanging side mine position of a certain open-air to underground metal mine in this embodiment, and the position of the transport road of the open-air transportation system is figure 1 In the area indicated by middle b, the hanging side mine comes from figure 1 The position indicated by middle a extends from the open-air slope to the outside of the open-pit upper slope c. According to the extension direction of the hanging side mine and the specific location of the open-pit transportation system above the hanging side mine, the mining area is firstly divided, and the hanging side The mine is divided into three divisions A, B, and C. Among them, Division A is close to the open-pit boundary, Division B is located directly below the open-pit transportation system, and Division C is the rest of the ore bodies except the above divisions. prospecting roadway;

[0033] Open-pit slope reinforcement: before mining the hanging side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com