Preparation method of sulfur-containing ammonium phosphate

A technology of sulfur-containing ammonium phosphate and diammonium phosphate, applied in the direction of phosphate and phosphorus-containing oxyacid, can solve the problems of uneven sulfur content, reduce the frequency of returning materials, etc. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

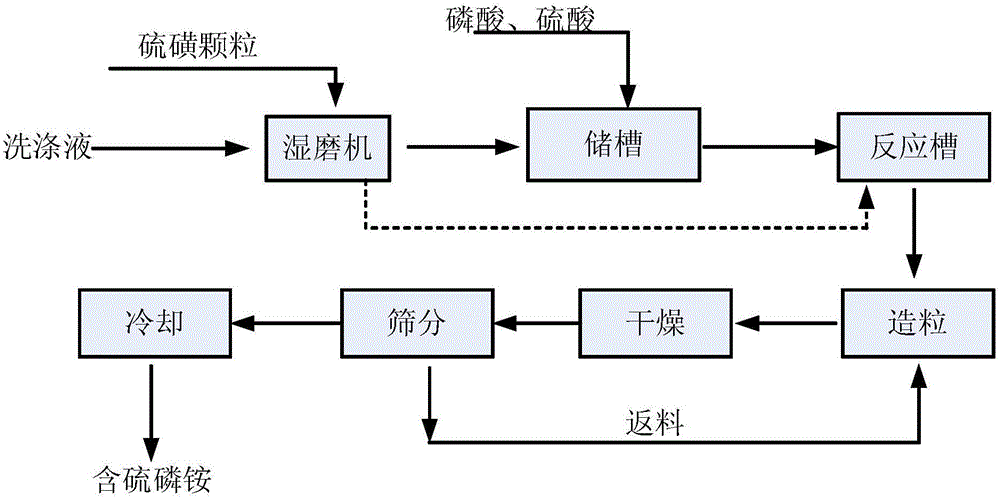

[0025] Production of sulfur-containing ammonium phosphate, such as figure 1 Shown:

[0026] Step 1: Add sulfur particles with a particle size of no more than 1cm to the wet mill through a belt in an amount of no more than 30% of the mass ratio after mixing with the washing liquid, and mix them with a specific gravity of 1.1g / L, pH=1, P 2 o 5 The calculated amount of 5% washing liquid was wet milled to obtain a sulfur-containing washing liquid with a particle size of 500 μm and a solid content of 40%, and material A was obtained.

[0027] The second step: producing sulfur-containing ammonium phosphate. Put the above material A into figure 1 Introduce it into a storage tank, add phosphoric acid with a concentration of 46%, transport it to a tubular reactor, granulate after the reaction is completed, dry with hot air below 250°C, crush and sieve to obtain sulfur-containing ammonium phosphate.

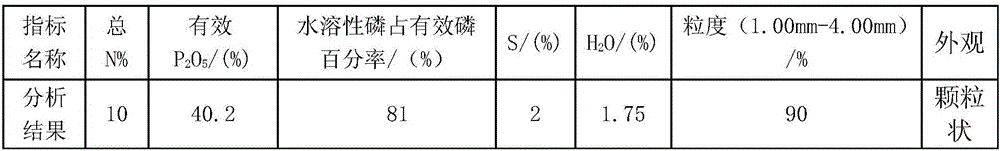

[0028] Table 1 Analysis results of sulfur-containing ammonium phosphate

[0029] ...

Embodiment 2

[0031] Step 1: Add sulfur particles with a particle size of no more than 1cm to the wet mill through a belt in an amount of no more than 45% of the mass ratio after mixing with the washing liquid, and mix the sulfur particles with a specific gravity of 1.15g / L, pH=2, P 2 o 5 The calculated amount of 12% washing solution was wet milled to obtain a sulfur-containing washing solution with a particle size of 75 μm and a solid content of 55%, and material A was obtained.

[0032] The second step: producing sulfur-containing ammonium phosphate. Put the above material A into figure 1 It is directly introduced into the reactor and mixed with the ammonium phosphate slurry in the reactor to obtain slurry B, which is transported to a granulator for granulation, dried with hot air below 250°C, crushed and screened to obtain sulfur-containing ammonium phosphate.

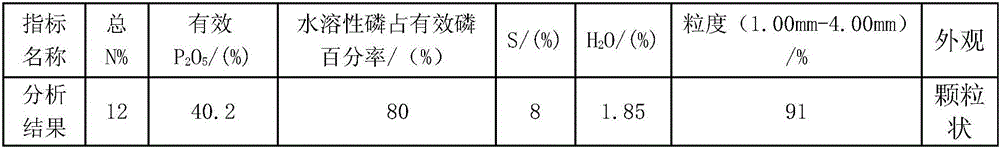

[0033] Table 2 Analysis results of sulfur-containing heavy calcium

[0034]

Embodiment 3

[0036] Step 1: Add sulfur particles with a particle size of no more than 1cm to the wet mill through a belt in an amount of no more than 60% of the mass ratio after mixing with the washing liquid, and mix them with a specific gravity of 1.2g / L, pH=3, P 2 o 5 The calculated amount of 20% of the washing solution was wet milled to obtain a sulfur-containing washing solution with a particle size of 20 μm and a solid content of 70%, and material A was obtained.

[0037] The second step: producing sulfur-containing ammonium phosphate. Put the above material A into figure 1 Introduce it into a storage tank, add phosphoric acid with a concentration of 46%, transport it to a tubular reactor, granulate after the reaction is completed, dry with hot air below 250°C, crush and sieve to obtain sulfur-containing ammonium phosphate.

[0038] Table 3 Analysis results of sulfur-containing ammonium phosphate

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com