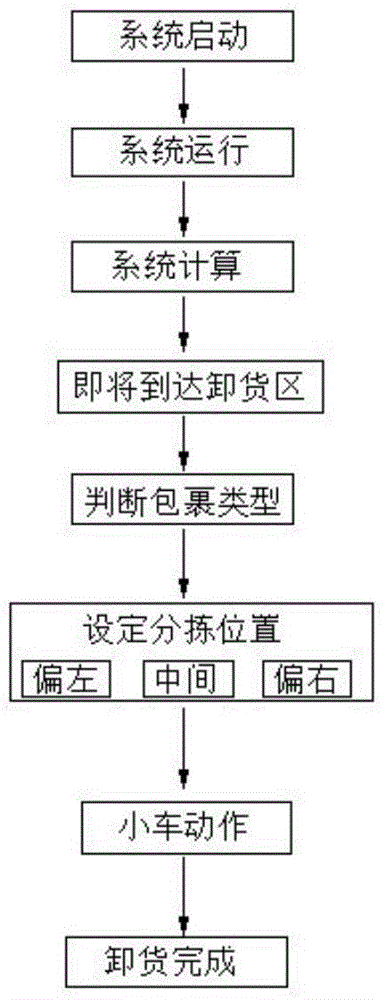

Unloading control method for crossed belt sorting machine

A cross-belt sorting and control method technology, applied in the direction of sorting, loading/unloading, transportation and packaging, etc., can solve the problems of package damage, regardless of weight, etc., to reduce weight, reduce damage rate, and improve sorting quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

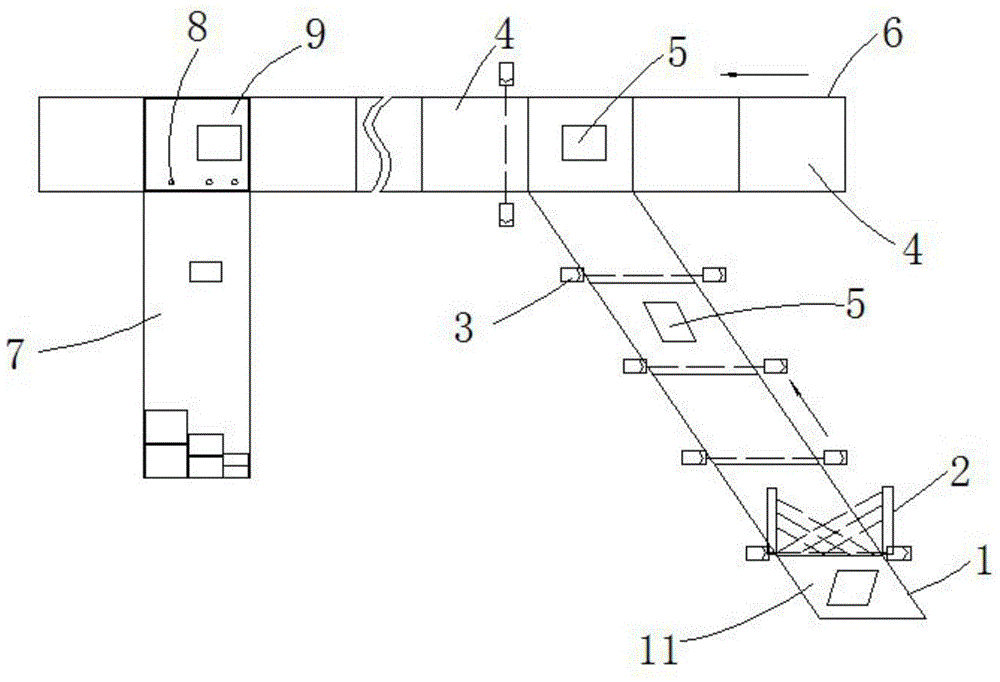

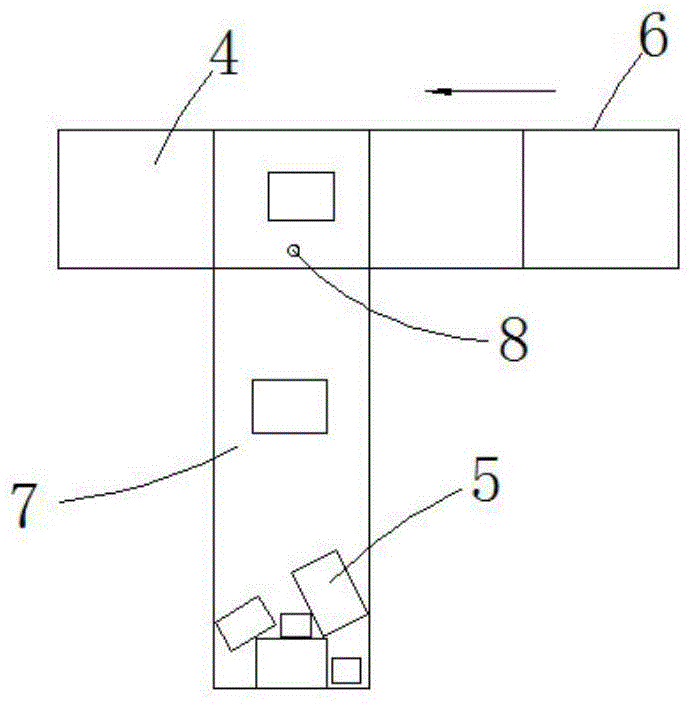

Embodiment 1

[0023] refer to figure 2 As shown, an unloading control method for a cross-belt sorter, including a trolley 4 equipped with a photoelectric cell 3, a conveying main line 6, a control system, a delivery conveyor belt 1 equipped with a grating 2 and a photoelectric cell 3, and a receiving area 7. The feeding conveyor belt 1 is used to put and transport the parcel 5 to the trolley 4, the trolley 4 is used to receive and transport the parcel 5 to the receiving area 7, and the main conveying line 6 is used to drive the trolley 4 Running forward, the grating 2 is used to detect the center position of the parcel 5 on the feeding conveyor belt 1, and collects the size and weight information of the parcel 5, and the photoelectric cell 3 is used to detect the parcel 5 on the feeding conveyor belt 1. The position on the conveying belt 1 or on the trolley 4, the control system is used to collect and process the detection information of the grating 2 and the photoelectric cell 3, adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com