A multipurpose material rack

A material rack and material box technology, which is applied in the field of multi-purpose material racks, can solve the problems of inconvenient transportation and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

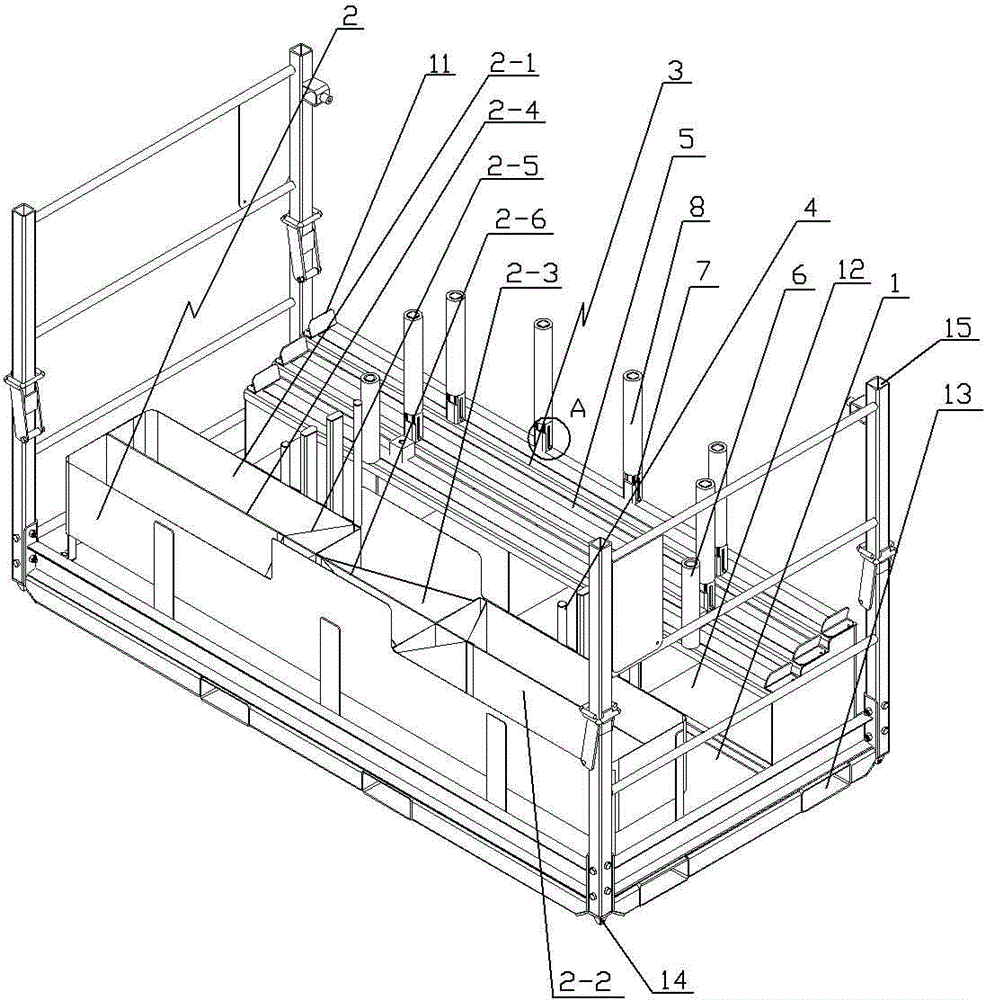

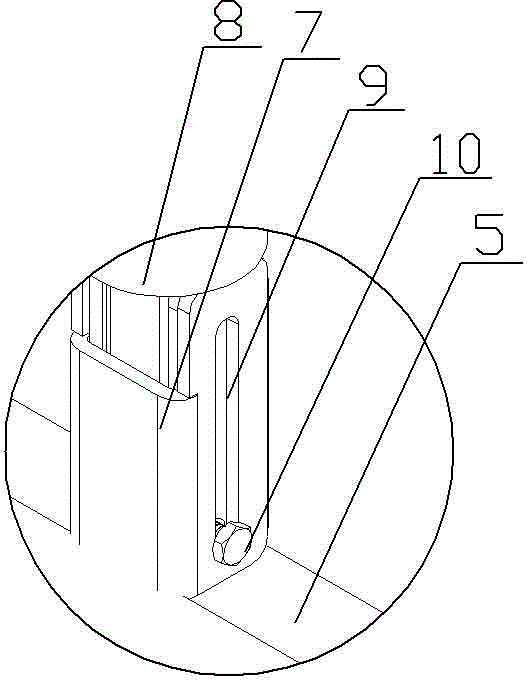

[0011] See figure 1 , figure 2 As shown, a multi-purpose material rack includes a bracket 1, a material box 2 and a support seat 3 are installed on the bracket 1, two rows of side stop bars 4 are symmetrically installed between the material box 2 and the support seat 3, and the material box 2 includes a left Side box 2-1, right box 2-2, middle box 2-3, left box 2-1 and right box 2-2 are symmetrically arranged, left box 2-1 and right box 2-2 are installed inside Transverse baffle 2-4 and two oblique baffles 2-5, lateral baffle 2-4 and oblique baffle 2-5 separate left side case 2-1, right side case 2-2 into four trapezoidal compartments The middle box 2-3 is arranged in the middle of the left side box 2-1 and the right side box 2-2, the middle box 2-3 is an isosceles triangle box, and the middle partition 2-6 is installed in the middle box 2-3, The middle partition 2-6 separates the middle box 2-3 into two right-angled triangle compartments, steps 5 are set on the support bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com