Compound type intermediate-temperature carbon dioxide adsorbent and preparation method thereof

A technology of carbon dioxide and adsorbent, which is applied in the field of new composite medium-temperature carbon dioxide adsorbent and its preparation, can solve the problems of low adsorption efficiency of warm carbon dioxide adsorbent, achieve good cycle regeneration performance, simple and easy process, and improve adsorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

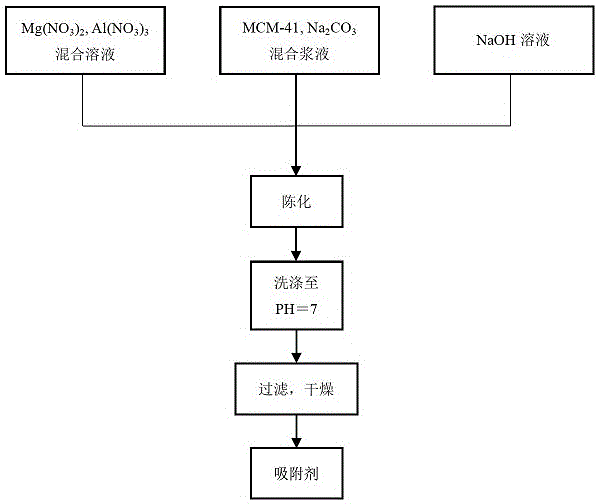

Method used

Image

Examples

Embodiment 1

[0022] First mix 1.0g of MCM-41 and 2.5g of Na 2 CO 3 Place in 10mL of deionized water, stir and mix evenly, configure mixed slurry A, and then add 6.0g of Mg(NO 3 ) 2 ·6H 2 O and 4.4g of Al(NO 3 ) 3 9H 2 O was added to 15mL deionized water to configure mixed solution B, and 3.5g NaOH was added to 10mL deionized water to configure alkaline solution C. B and C solutions were simultaneously added dropwise to the slurry A, and the pH was kept between 10-12, and vigorously stirred during the dropwise addition. Aged at 60°C for 12 hours, then repeatedly washed until the pH of the solution was 7, and the solid powder obtained after filtration was dried in a high-temperature drying oven at 120°C for 24 hours, and then taken out to obtain the required adsorbent.

Embodiment 2

[0024] First mix 1.0g of MCM-41 and 4.0g of Na 2 CO 3 Place in 16mL of deionized water, stir and mix evenly, configure mixed slurry A, and then add 9.7g of Mg(NO 3 ) 2 ·6H 2 O and 7.1g of Al(NO 3 ) 3 9H 2 O was added to 24mL deionized water to make mixed solution B, and 5.5g NaOH was added to 16mL deionized water to make alkaline solution C. B and C solutions were simultaneously added dropwise to the slurry A, and the pH was kept between 10-12, and vigorously stirred during the dropwise addition. Aging at room temperature 25°C for 18 hours, and then repeated washing until the pH value of the solution was 7, the solid powder obtained after filtration was dried in a high-temperature drying oven at 95°C for 30 hours, and then taken out to obtain the required adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com