Composite hydrocolloid and preparation method thereof and hydrocolloid dressing and preparation method of hydrocolloid dressing

A technology of hydrocolloid and hydrocolloid layer, which is applied in capsule delivery, microcapsules, pharmaceutical formulations, etc. It can solve the problems of unproven safety, lack of adsorption, and unsustainable efficacy, so as to improve the healing effect and benefit growth , the effect of promoting wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

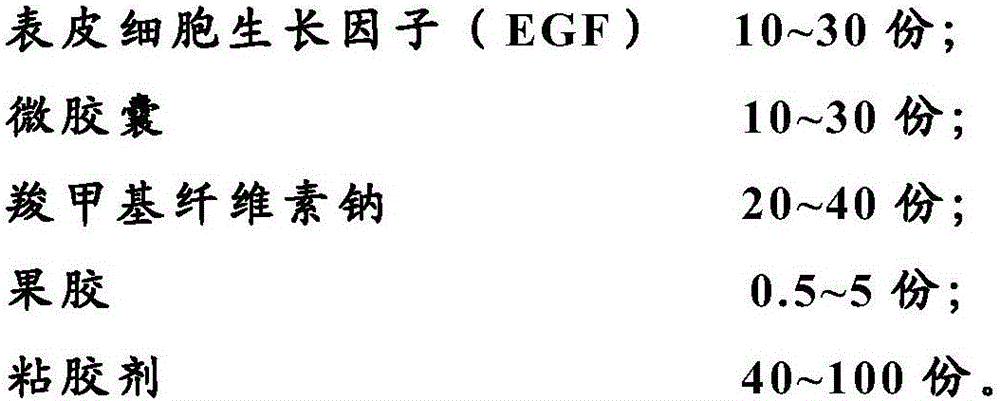

Method used

Image

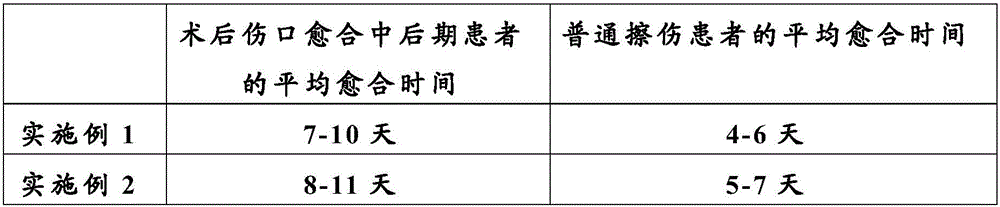

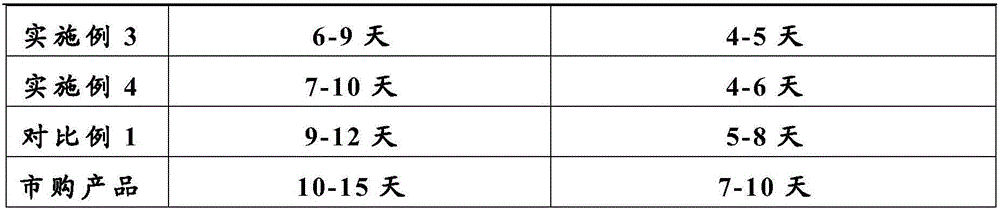

Examples

Embodiment 1

[0031] A hydrocolloid dressing, its preparation method is as follows:

[0032] Step (1), heating 40 parts by weight of polyisobutylene medical hot-melt adhesive to 110°C in a mixer to melt to form component A;

[0033] Step (2), mixing 10 parts by weight of the epidermal growth factor stock solution and 10 parts by weight of hyaluronic acid microcapsules at 2°C to prepare component B;

[0034] Step (3), adding 20 parts by weight of sodium carboxymethyl cellulose and 0.5 parts by weight of pectin to component A, stirring at a constant temperature in vacuum at 110°C for 50 minutes, then adding component B, vacuuming at 100°C Stir at constant temperature for 5 minutes to make a composite hydrocolloid;

[0035] Step (4), injection molding the composite hydrocolloid on the polyurethane film, and then performing aging treatment at 35° C. for 60 hours to form the composite hydrocolloid layer, covering the composite hydrocolloid layer with the polyurethane film, and then molding it t...

Embodiment 2

[0037] A hydrocolloid dressing, its preparation method is as follows:

[0038] Step (1), heating 100 parts by weight of polyisobutylene medical hot-melt adhesive to 150°C in a mixer to melt to form component A;

[0039] Step (2), mixing 30 parts by weight of the epidermal growth factor stock solution and 30 parts by weight of hyaluronic acid microcapsules at 8°C to prepare component B;

[0040] Step (3), adding 40 parts by weight of sodium carboxymethyl cellulose and 5 parts by weight of pectin to component A, stirring at a constant temperature in vacuum at 130°C for 100 min, then adding component B, vacuuming at 120°C Stir at constant temperature for 15 minutes to make a composite hydrocolloid;

[0041] Step (4), injection molding the composite hydrocolloid on the polyurethane film, and then performing aging treatment at 65° C. for 60 h to form the composite hydrocolloid layer, covering the composite hydrocolloid layer with release paper, and then molding into a suitable Th...

Embodiment 3

[0043] A hydrocolloid dressing, its preparation method is as follows:

[0044] Step (1), heating 70 parts by weight of polyisobutylene medical hot-melt adhesive to 130°C in a mixer to melt to form component A;

[0045] Step (2), mixing 20 parts by weight of the epidermal growth factor stock solution and 20 parts by weight of hyaluronic acid microcapsules at 5°C to prepare component B;

[0046] Step (3), add 30 parts by weight of sodium carboxymethyl cellulose and 2 parts by weight of pectin to component A, stir at 120°C for 70 minutes at a constant temperature in vacuum, then add component B, and vacuum at 110°C Stir at constant temperature for 10 minutes to make a composite hydrocolloid;

[0047]Step (4), injection molding the composite hydrocolloid on the non-woven fabric, then performing aging treatment at 45° C. for 60 h to form the composite hydrocolloid layer, covering the composite hydrocolloid layer with release paper, and then molding into It is suitable for the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com