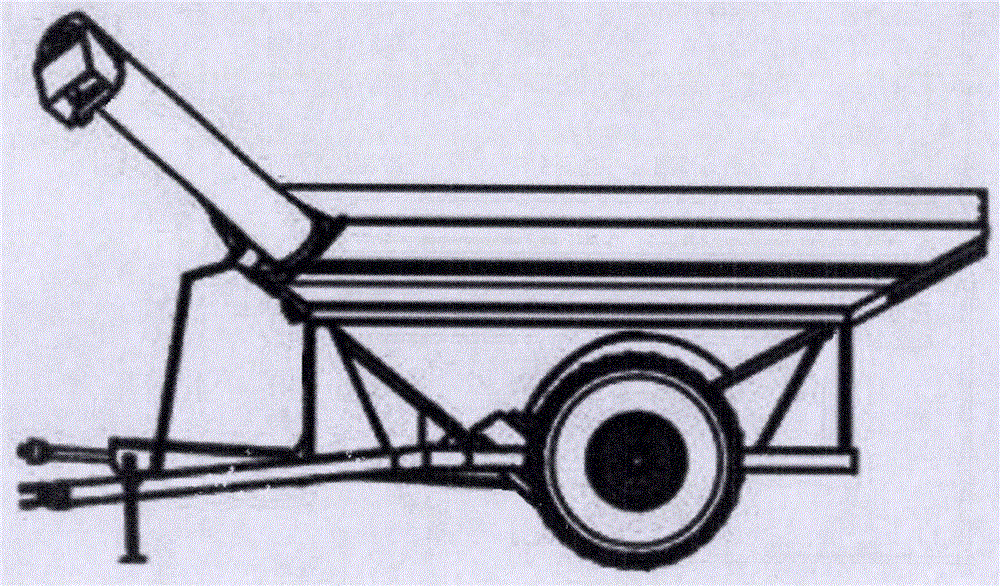

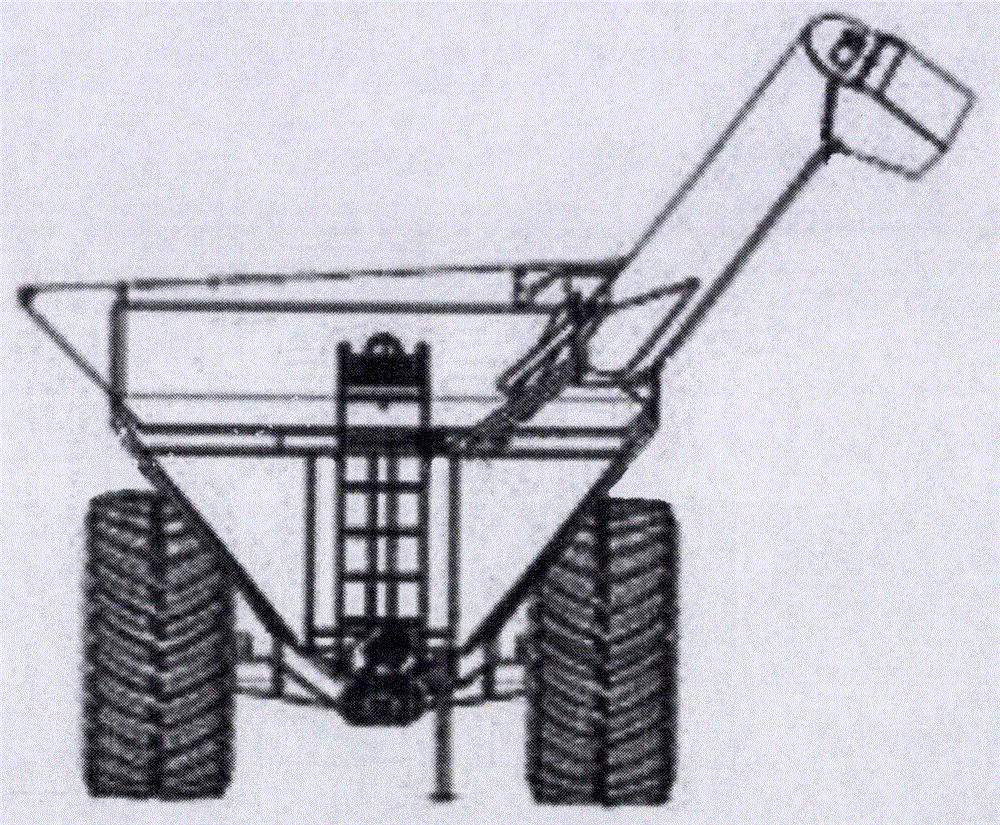

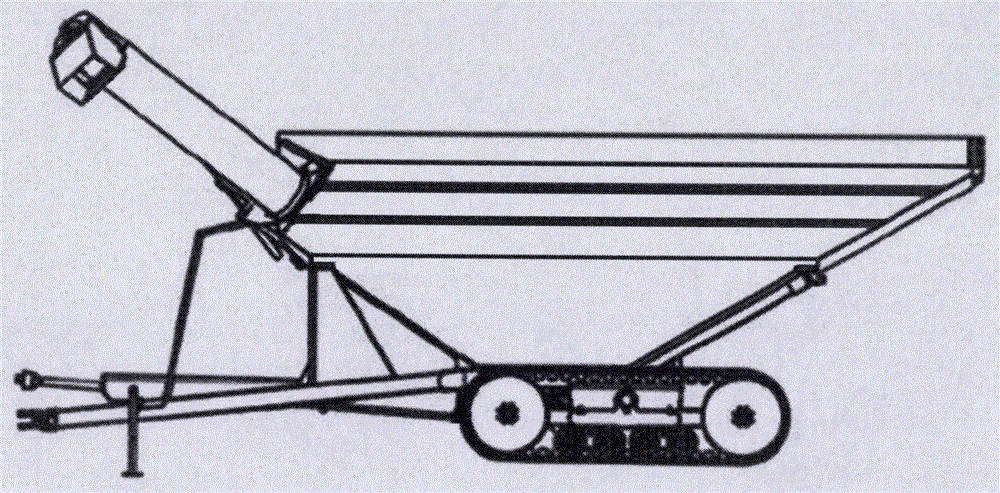

Grain cart with driving capability

A technology for grain trucks and driving axles, applied in applications, loaders, agricultural machinery and implements, etc., can solve problems such as large damage to farmland and field roads, inability to transport grain to grain stores, and inability of trailers to provide driving force, etc. The effect of weight balance, reasonable structure design and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiment of the present invention is described in detail below, and the grain cart driven by the belt is composed of: traction frame, drive axle, planetary wheel side reducer, grain hopper, oil cylinder, girder, drive wheel, power distribution system, screw conveyor , which is characterized in that: the power is transmitted from the supporting equipment to the power distribution system through the transmission shaft, and from the power distribution system to the screw conveyor and the walking system. When the screw conveyor needs to work, the power distribution system transmits the power to the screw conveyor. When the driving wheels are required to work, the power distribution system transmits the power to the drive axle, the drive axle transmits the power to the wheel side reducer, and the wheel side reducer transmits the power to the driving wheels.

[0015] While this invention has been described as having an exemplary design, further modifications ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com