Electric cabinet device control system

A device control and electrical cabinet technology, applied in the field of electrical cabinets, can solve the problems of difficult control of pivot angle, manual operation, and difficult operation, and achieve the effect of compact structure, convenient use and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

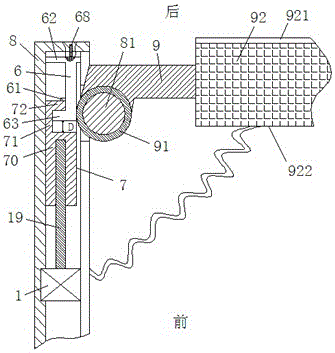

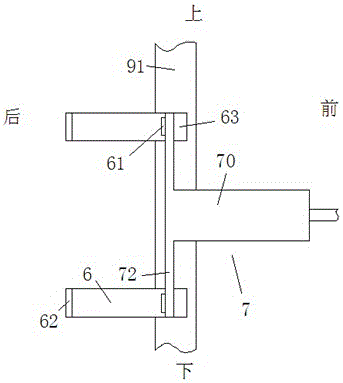

[0012] Combine below Figure 1-3 The present invention will be described in detail.

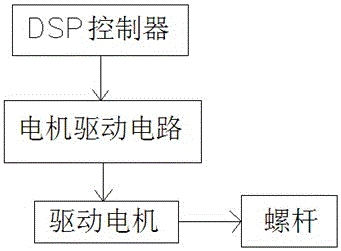

[0013] According to an embodiment of an electrical cabinet device control system, it includes a fixed frame part 8 and a functional device carrier 9 that is pivotable relative to the fixed frame part 8, and the functional device carrier 9 is loaded with an operating side 921 and the functional device device 92 on the wiring side 922, the end of the functional device carrier 9 close to the fixed frame part 8 is fixedly arranged with the hinge shaft 81 fixedly arranged near the rear end of the fixed frame part 8. A pivoting drive gear sleeve 91 that is rotatably matched, the fixed frame part 8 is provided with a rack assembly that can move in the forward and backward direction driven by the screw rod 19 extending in the forward and backward direction driven by the drive motor 1, and the DSP control The device is electrically connected to the drive motor 1 in the electrical cabinet device throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com