Combined-type permanent magnet pole drive motor rotor production method

A technology for driving motors and production methods, which is applied in the manufacture of motor-generators, magnetic circuit rotating parts, and stator/rotor bodies, etc., can solve problems such as drop, drive motor efficiency reduction, irreversible demagnetization, etc., and achieve high output power, The effect of high magnetic field strength and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with accompanying drawing:

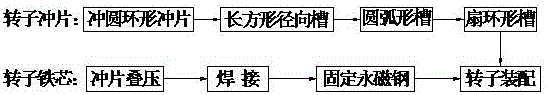

[0008] The combined permanent magnet pole-driven motor rotor production method is characterized in that: punching and cutting circular rotor punches, the rotor punches are evenly distributed with an even number of rectangular radial grooves with the same shape and size running through the thickness of the rotor punches, the rectangular diameter The outer edge of the groove is a convex arc, and the arch height of the convex arc is 1mm. There is a 1.5mm disconnected part between the top of the convex arc and the outer circle of the rotor punch. In the middle of the outer end, there is an arc-shaped groove that runs through the thickness of the rotor punch and faces the outer circle of the rotor punch. The arc-shaped groove is not connected to the rectangular radial groove. There is a disconnected part of 1.5mm between the outer circles. The inner edge of each rectangular radi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arch high | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com