Glue detection method and device

A glue testing and gluing technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as poor efficiency of hot melt adhesives, and achieve the effect of improving efficiency and reducing wastage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

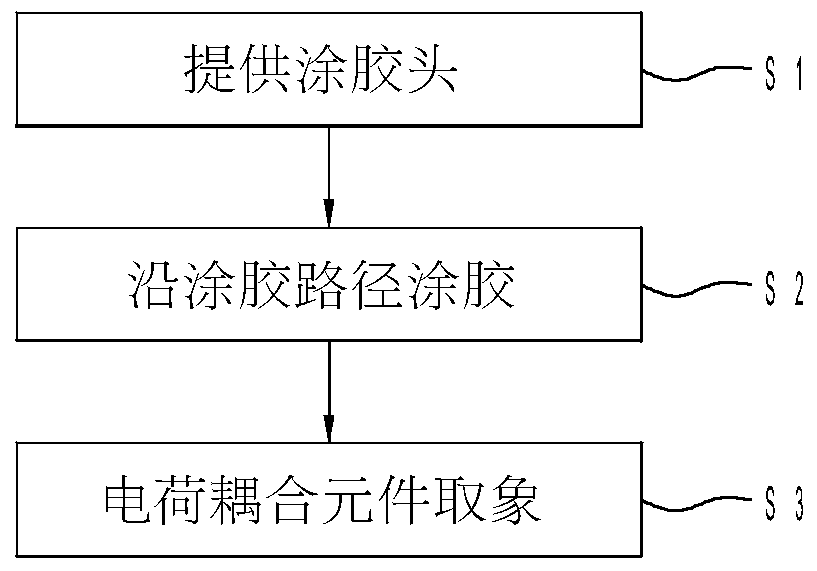

[0028] see figure 1 , illustrating the glue detection method provided by the present invention, including implementing the following steps S1 to S3:

[0029] Step S1: providing a glue applicator.

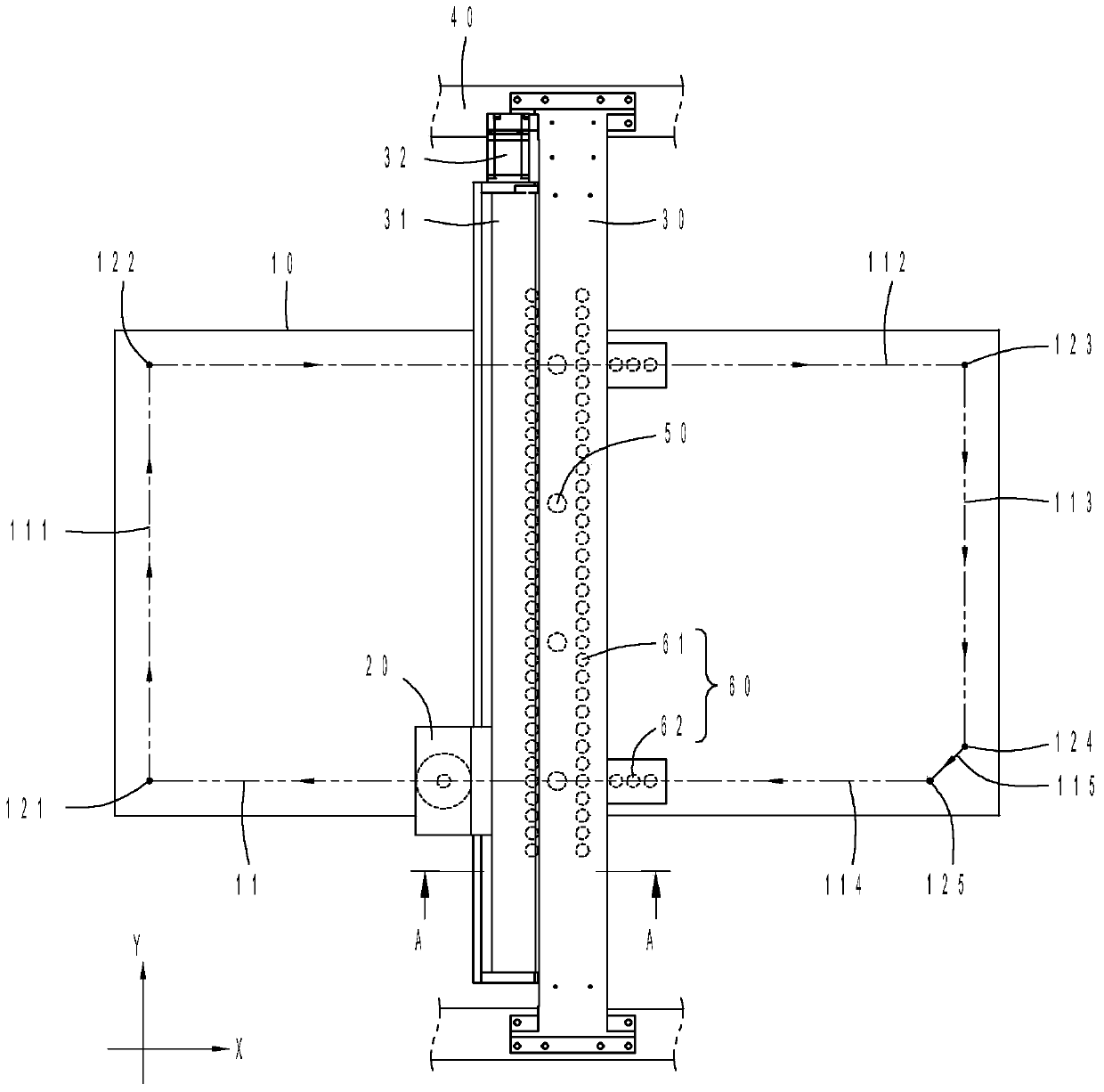

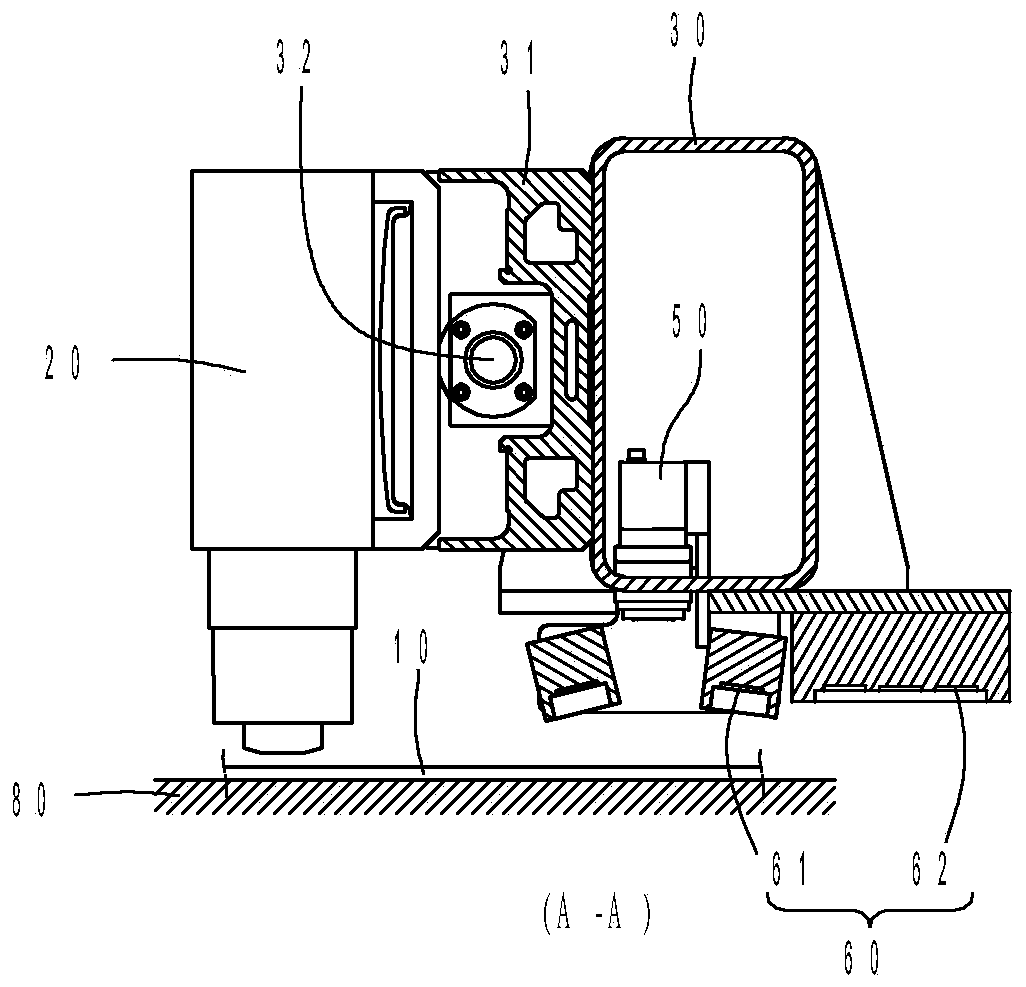

[0030] implementation, such as figure 2 As shown, the present invention provides a glue applicator 20 with biaxial movement capability. The above-mentioned biaxial refers to the X axis and the Y axis in practice. The X-axis and the Y-axis move, so that the hot melt adhesive contained in the glue head 20 is coated on the object (such as a substrate).

[0031] Step S2: apply glue along the glue application path.

[0032] implementation, such as figure 2 As shown, it is illustrated that the substrate 10 is moved to the bottom of the gluing head 20 through a carrier (such as a chain, a belt, or a roller, etc.). The glue path 11 is coated with hot melt glue on the substrate 10. The glue path 11 is formed around a quadrilateral track in practice, and the quadrilateral track is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com