Pre-applied shearing strength test piece, preparation device and preparation method for test piece and splitting test method

A shear stress and test piece technology, which is used in the application of stable shear force to test the strength of materials, the preparation of test samples, and the use of stable tension/pressure to test the strength of materials, etc. Problems such as setting and configuration, to achieve the effect of simple method and simple preparation

Active Publication Date: 2016-07-20

HUANENG LANCANG RIVER HYDROPOWER +2

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It can be seen that there is no relevant experimental method and supporting equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

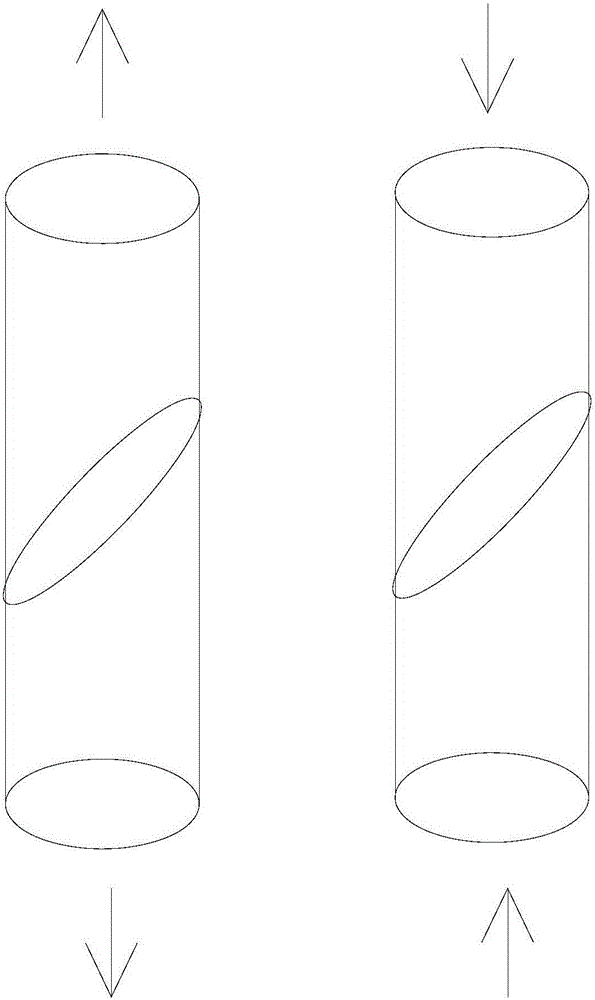

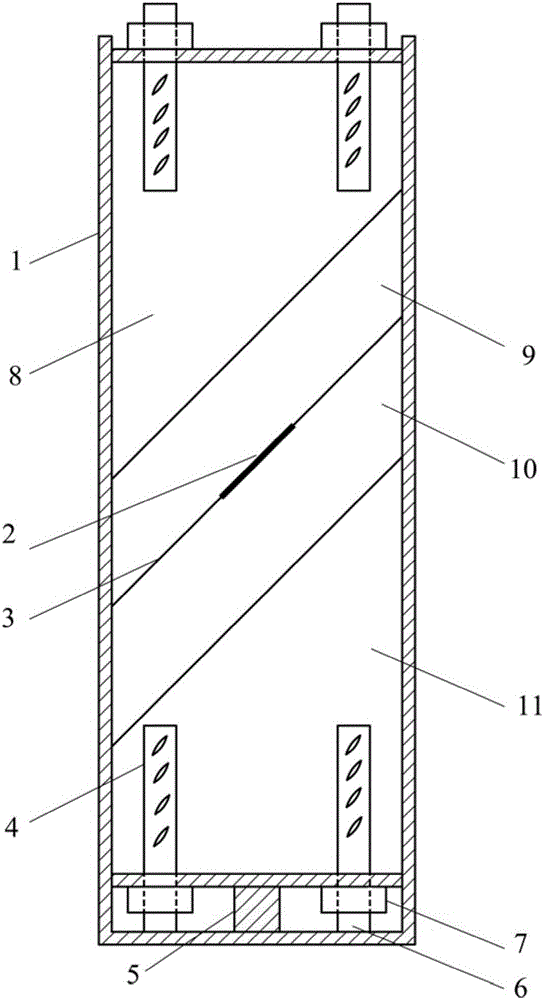

The invention relates to a pre-applied shearing strength test piece, a preparation device and a preparation method for a test piece and a splitting test method. The invention aims to overcome the defects that only a single-axial tensile pressing condition is considered and the shearing strength is difficult to consider on the basis of the traditional high pressure water splitting simulation test design method and traditional high pressure water splitting simulation test design device and the test piece only can be normal concrete. The test piece has an extending direction; an inclined layer is arranged on the middle position along the length direction of the extending direction; an included angle alpha is formed between the inclined layer and a preset direction; a preset crack is arranged on the inclined layer; the preset crack is communicated with the exterior of the test piece through an interface channel. According to the test method, the preset crack is filled with high pressure water till the preset crack is split and a single-shaft test device is used for applying the shearing strength to the test piece. The test piece, the device and the test method provided by the invention can consider the influence of the shearing strength of the roller compacted concrete, so that the working condition of the roller compacted layer of a roller compacted concrete high-dam under the effect of high pressure water can be effectively simulated.

Description

technical field [0001] The invention provides a technique for splitting test of roller compacted concrete under high pressure water in the field of water conservancy and hydropower engineering, especially a test piece for splitting test of roller compacted concrete with high pressure water that can be pre-added shear stress, and preparation of the test piece. The device and preparation method of the test piece, as well as the splitting test method of the roller compacted concrete with high pressure water that can be pre-stressed by using the test piece. Background technique [0002] With the increasing demand for water resources development and the advancement of engineering technology, the construction of high dams and large reservoirs is increasing, and ultra-high concrete gravity dams with a dam height of more than 200m continue to emerge. The increase in dam height has brought new problems, especially for RCC dams, where there is a weak layer of rolling. Whether the weak...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/24G01N3/12G01N1/28

CPCG01N1/28G01N3/12G01N3/24

Inventor 贾金生艾永平郑爱武汪洋郑璀莹刘中伟赵春杨会臣汪强迟福东庞博慧陈鸿杰

Owner HUANENG LANCANG RIVER HYDROPOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com