Self-centering double shear test device and type II fracture toughness test method

A technology of double-sided shearing and testing device, which is applied in the direction of applying stable shearing force to test the strength of materials, can solve the problems of continuous shearing of rock samples, large tonnage and limited strength parameters, and achieves wide applicability and easy manufacturing. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Shear shear test of rock samples.

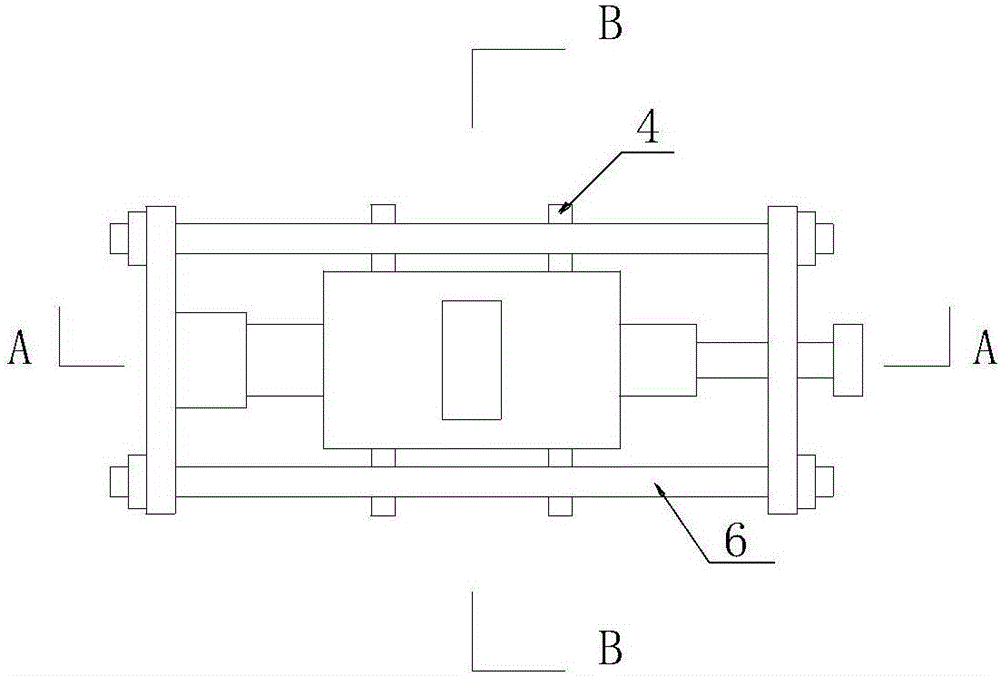

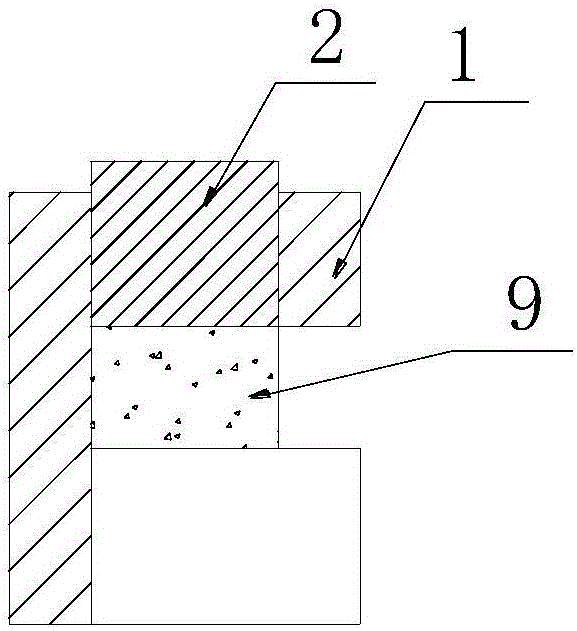

[0028] Depend on figure 1 , figure 2 It can be known that the rock sample shear resistance test uses a self-centering double-sided shear test device, which includes a shear fixture, a horizontal loading frame, and a normal force loading device. The shear fixture includes a sample Box 1, shear briquetting block 2, first normal briquetting block 301 and second normal briquetting block 302, sample box 1 is made of high-strength steel, and support ears 4 are arranged on the outer edges of both sides, sample box 1 There are horizontal through holes and vertical through holes inside, the horizontal through holes are perpendicular to the vertical through holes, there is an observation hole in the middle of one side of the sample box 1, the rock sample 9 is placed in the center of the horizontal through hole, and the two ends of the rock sample 9 Install the first normal pressure block 301 and the second normal pressure block 30...

Embodiment 2

[0032] Embodiment 2: Testing of rock sample shear strength parameters.

[0033] The same self-centering double-sided shear test device as in Example 1 was used.

[0034] The main process of testing the shear strength parameters of rock samples is as follows:

[0035] Step 1, the rock sample 9 is installed in the center of the horizontal through hole of the sample box 1, and the first normal briquetting block 301 and the second normal briquetting block 302 are respectively installed at both ends of the rock sample 9. surface position, after adjusting the positions of the normal force loading device 8, the first normal briquetting block 301, the second normal briquetting block 302 and the rock sample 9, fix the position adjustment rod 7, and the test piece above the rock sample 9 The vertical through hole of the sample box 1 is installed with a shearing block 2, and then the self-aligning double-sided shearing test device is installed in the loading frame of the rock mechanics ...

Embodiment 3

[0045] Example 3: Test of Rock Mode II Fracture Toughness.

[0046] The same self-centering double-sided shear test device as in Example 1 was used.

[0047] The main process of rock mode II fracture toughness testing is as follows:

[0048] Step 1, the main process of the rock mode II fracture toughness test is as follows: firstly, double-notch cracks are prefabricated on the rock sample 9, the rock-soil sample 9 is a cube, the interval between the double notches is d, and the incision depth of the double notches is c, the width of the double notch is the same as that of the rock sample 9, the width of the rock sample 9 is B, the height of the rock sample (9) is a, the length of the rock sample 9 is L, and the interval between the double notches is d and The length of the shear compact 2 is the same, 0.3 c a 0.7 ;

[0049] Step 2, the rock sample 9 is installed in the center of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com