Clamp for testing I type interlayer fracture toughness of composite material

A technology for interlaminar fracture toughness and test fixtures, applied in the direction of analyzing materials, measuring devices, strength characteristics, etc., can solve problems such as high labor intensity, reduced efficiency, fatigue, etc., to reduce labor intensity, reduce operating links, and solve cumbersome operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

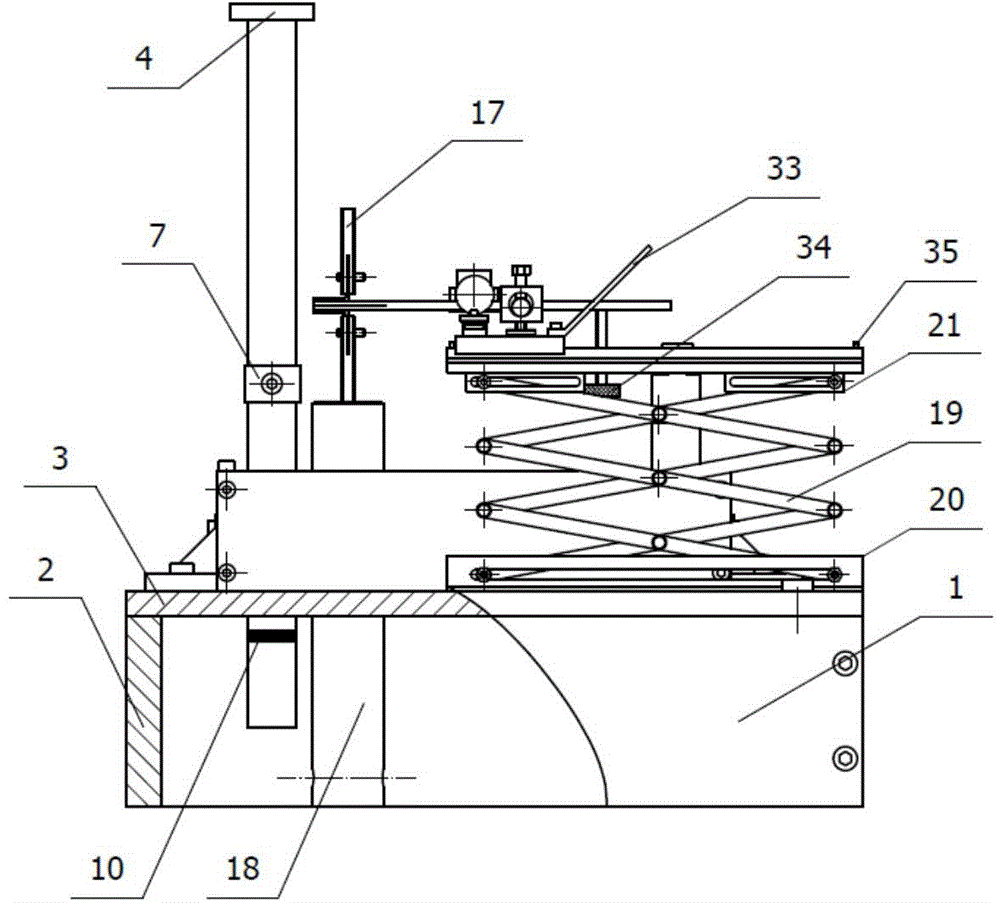

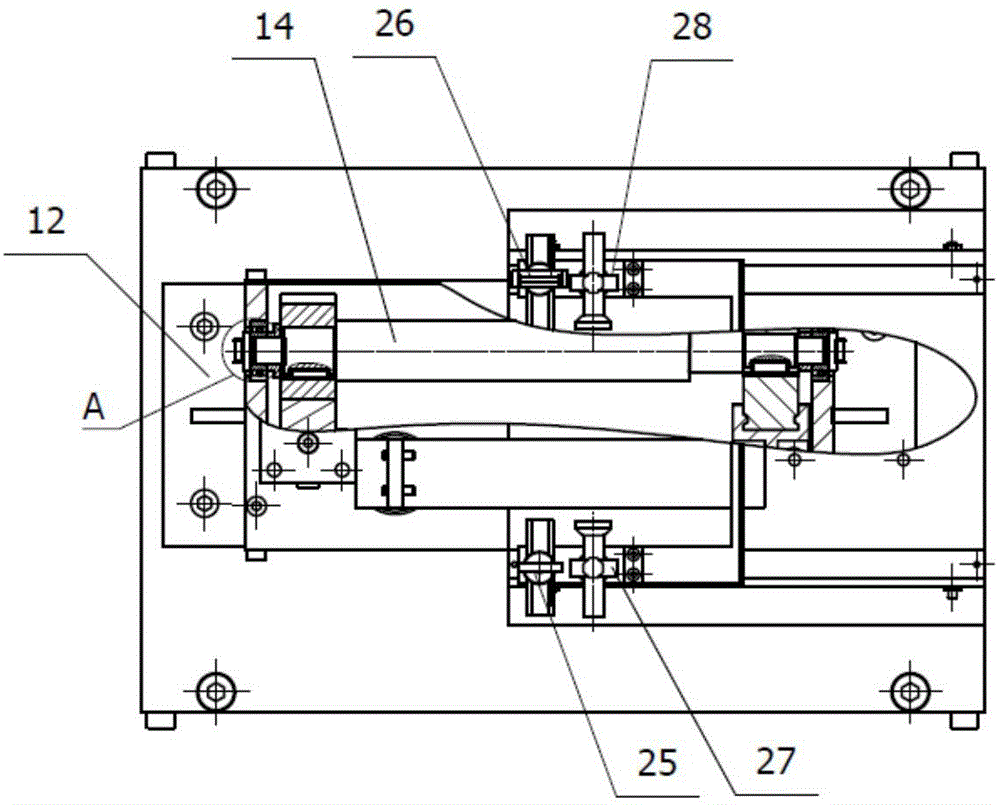

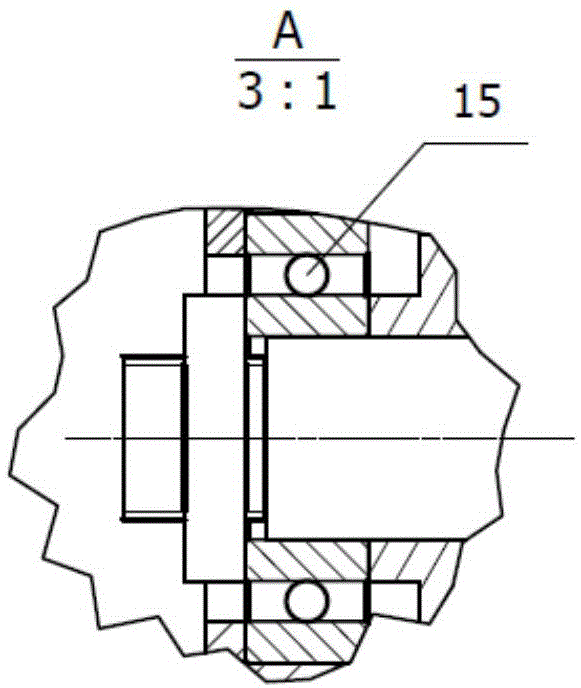

[0022] Such as Figure 1 to Figure 5 As shown, a type I interlaminar fracture toughness test fixture of composite materials, the fixture is composed of a base, a transmission device, a clamping device and an observation platform:

[0023] The base includes a front panel 1, a side panel 2 and an upper panel 3, and the lower surface of the upper panel 3 is in contact with the upper surfaces of the front panel 1 and the side panel 2 and is connected by bolts; the transmission device includes a beam connecting seat 4, an active Rack 5, first constraint guide rail 6, limit slider 7, driven rack 8, second constraint guide rail 9, limit marking line 10 and gear box, upper surface of driving rack 5 and lower surface of beam connecting seat 4 Contact and fixed by bolts, the upper surface of the crossbeam connecting seat 4 is in contact with the crossbeam and fixed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com