Unbalance ridding mechanism for cross-flow fan dynamic balance emendation

A cross-flow fan blade and deduplication technology, which is used in static/dynamic balance testing, machine/structural component testing, measuring devices, etc. The effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

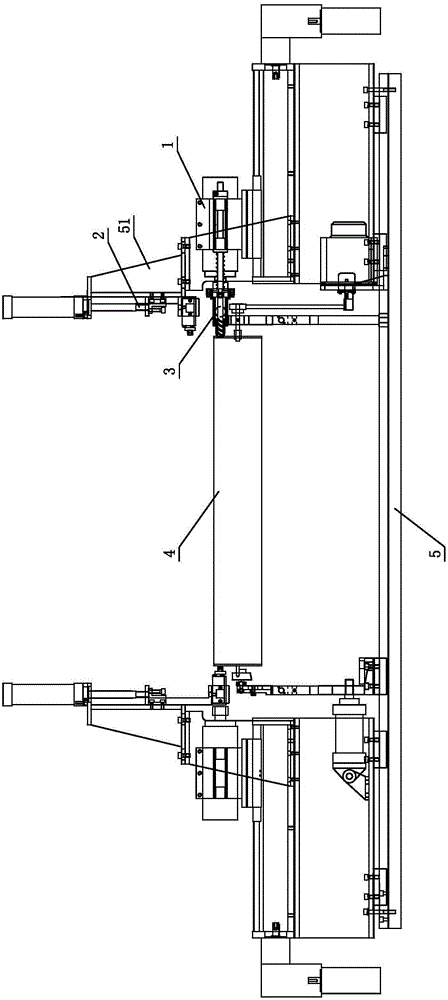

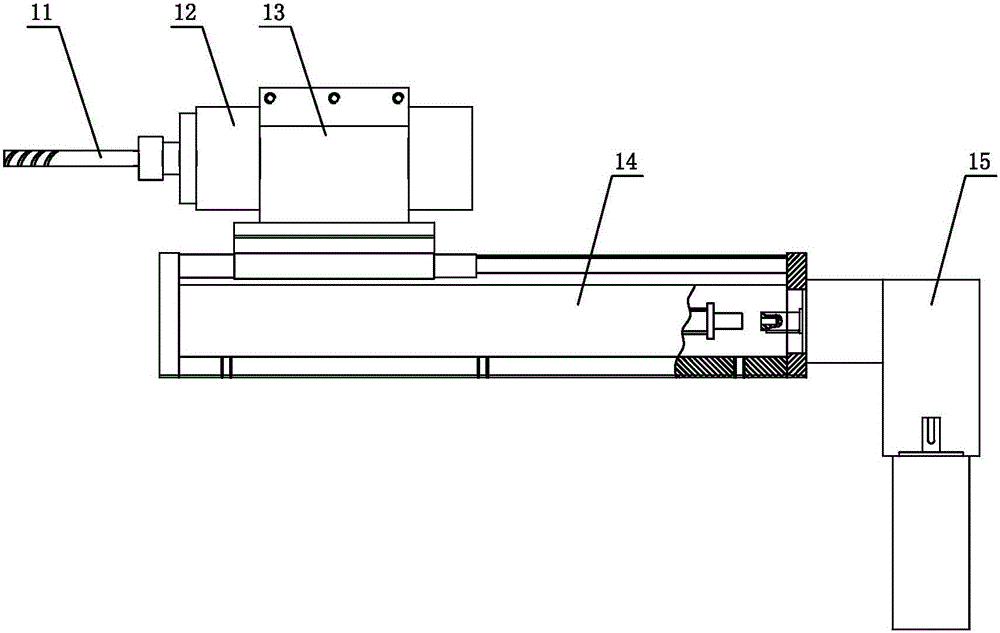

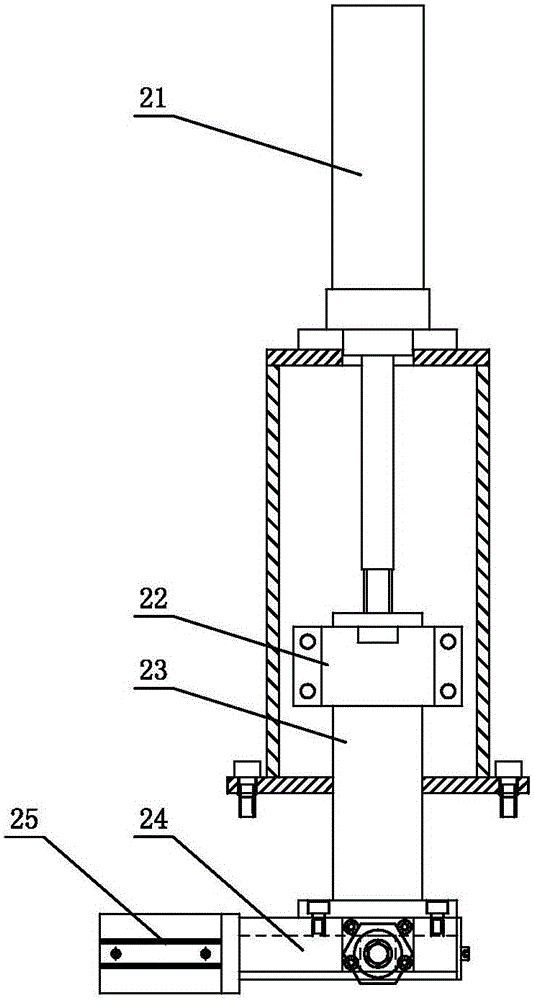

[0027] see Figure 1-Figure 6 , the weight removal mechanism used for the dynamic balance correction of cross-flow fan blades, including a base 5, the cross-flow fan blades 4 are clamped on the base 5, and the base 5 is provided with drilling and reorganization for drilling weight removal Part 1, an end face tightening assembly 2 for counteracting the drilling force, and a debris absorption assembly 3 for removing debris; Two sets are respectively placed at both ends of the cross-flow fan 4. Specifically, the drilling and weight removal component 1, the end face tightening component 2 and the debris absorption component 3 are symmetrically distributed on the cross-flow fan 4 along the central section of the cross-flow fan 4. Both ends; the end surface tightening mechanism 2 is independently installed on the small gantry frame 51 of the base 5 . When the drilling and milling cutter 11 on the drilling and removing weight component 1 is drilling, the end face tightening componen...

no. 2 example

[0036] see Figure 7 , this weight-removing mechanism for cross-flow fan blade dynamic balance correction is different from the first embodiment in that: the debris absorption assembly 3 includes a drilling sleeve 31, a drilling sleeve bracket 32 and a sliding guide rod 33, The drilling sleeve 31 is fixedly connected to the drilling sleeve bracket 32, and two sliding guide rods 33 are arranged and distributed on both sides of the symmetry. On the motor base 13 of the drilling weight removal assembly 1, a spring 34 is sleeved on the sliding guide rod 33, and the two ends of the spring 34 act on the drilling sleeve bracket 32 and the guide rod seat 37 respectively, and the sliding guide rod 33 A locking block 36 is assembled through the end of the drilling sleeve support 32 to adjust the movement range of the drilling sleeve 31 , thereby adjusting the drilling depth.

[0037] Other parts not described are the same as those of the first embodiment, and will not be analyzed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com