Pipeline noise control method and device based on multi-model self-adaptive switching

A technology of adaptive switching and noise control, applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., to achieve a wide range of applications, easy implementation, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

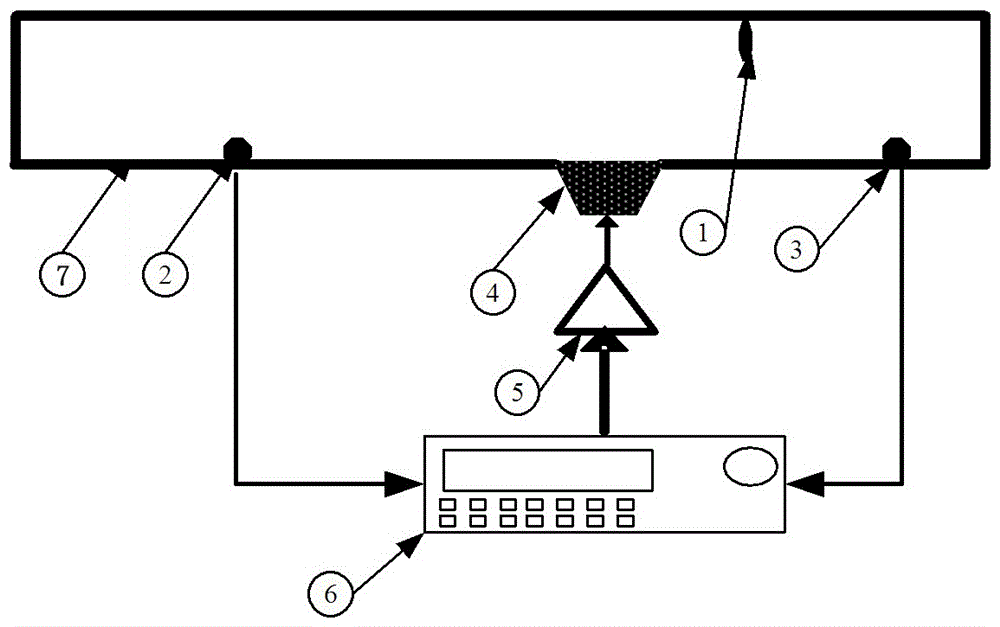

[0022] Example: see figure 1 , figure 2 , image 3 and Figure 4 , in the figure, 1-sound velocity sensor, 2-reference noise sensor, 3-error noise sensor, 4-noise suppression speaker, 5-noise suppression power amplifier, 6-embedded noise active controller, 7-pipeline.

[0023] A pipeline noise control method based on multi-model adaptive switching, the steps of which are:

[0024] a. A sound velocity sensor 1, a reference noise sensor 2, an error noise sensor 3 and a noise suppression speaker 4 are respectively installed at different positions inside the pipeline 7;

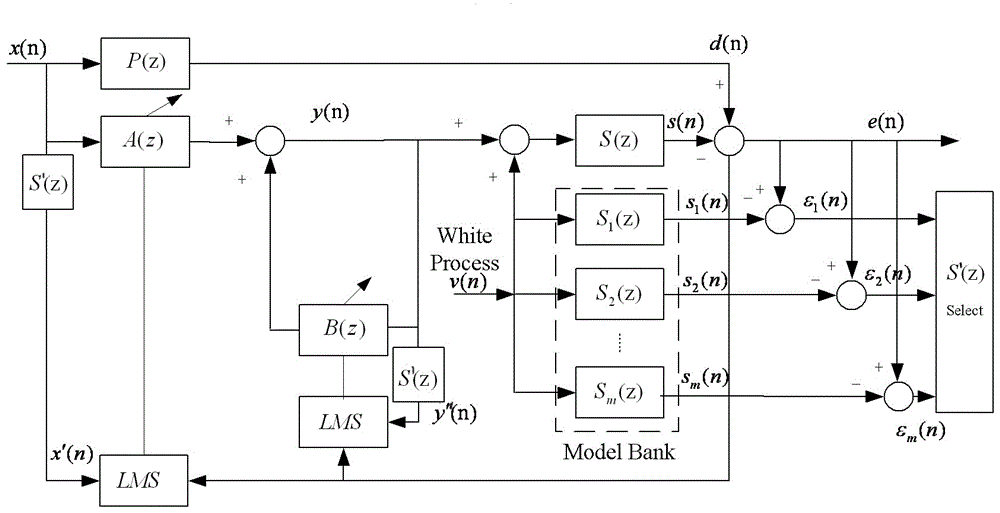

[0025] b. The pseudo-random noise is played in the pipeline 7 through the noise suppression speaker 4, and the active controller collects the detection signal of the error noise sensor 3, and obtains ten fixed parameter models S through the least mean square algorithm and comparing different temperature values 1 (z) to S 10 (z), and build a multi-model set containing ten fixed-parameter models;

[0026] c....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com