A dual-input micro-integrated differential planetary gear

A planetary gear, one-piece technology, applied in belts/chains/gears, transmission parts, components with teeth, etc., can solve the problems of large volume, limited number of teeth and modules of planetary gears, difficult differential transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

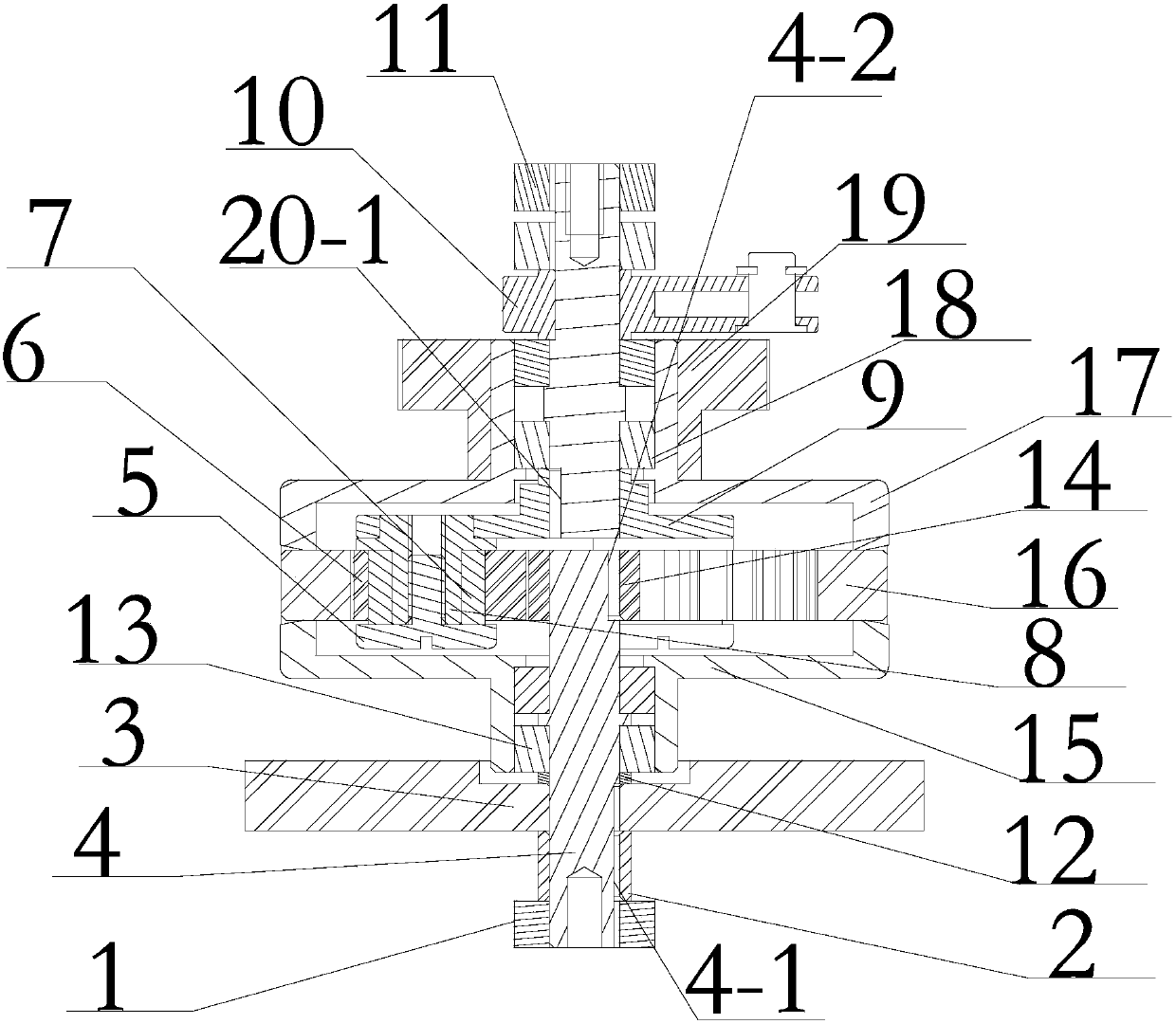

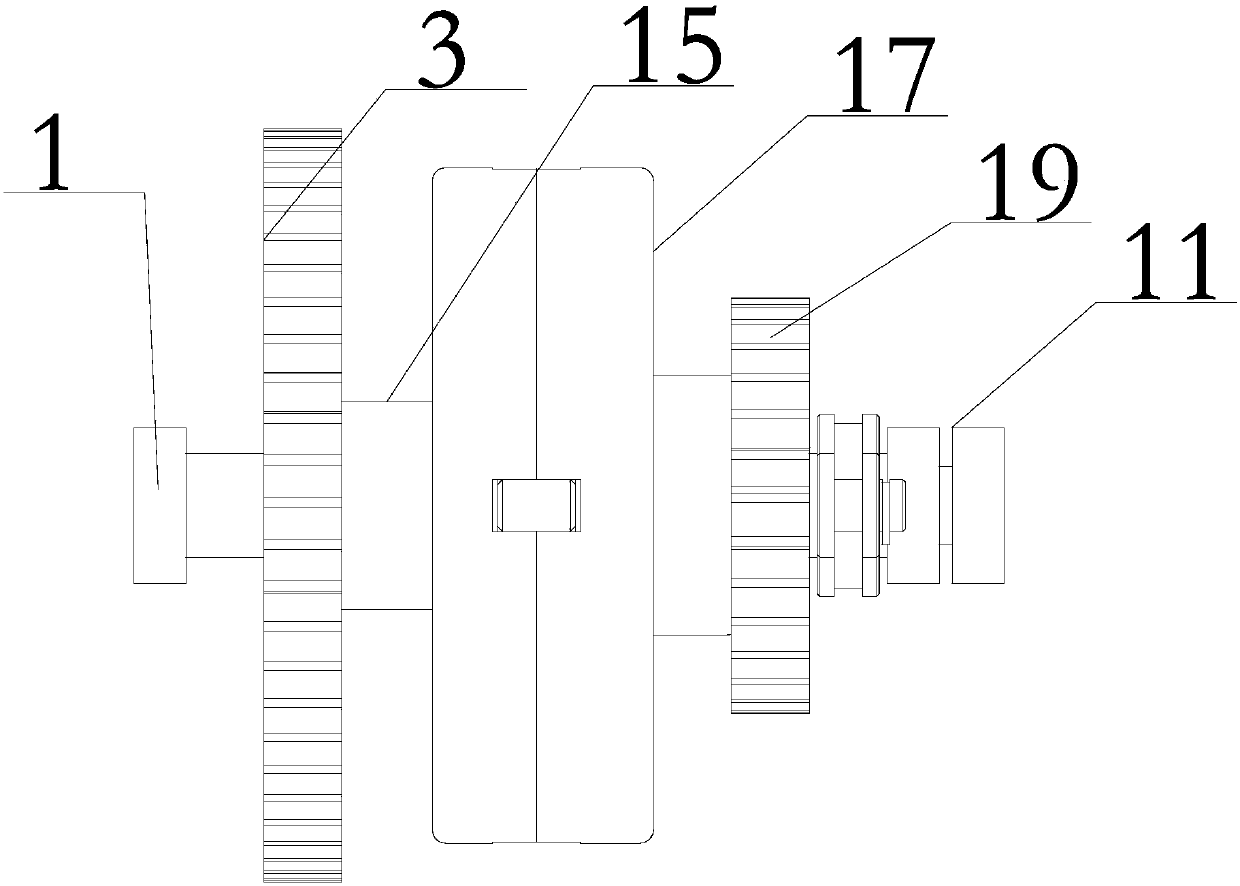

[0010] Specific implementation mode one: combine Figure 1-Figure 4 This embodiment is described. The dual-input micro-integrated differential planetary gear described in this embodiment includes an input shaft end bearing 1, an input shaft sleeve 2, an input shaft gear 3, an input shaft 4, a planetary gear assembly, and an output shaft Connecting rod 10, output shaft end bearing 11, gear carrier gear 19, output shaft 20, two input shaft middle bearings 13 and two output shaft middle bearings 18, input shaft end bearing 1, input shaft sleeve 2 and input shaft gear 3 The input shaft 4 is sequentially set on the input shaft 4 from the input end to the output end. The output end of the input shaft 4 passes through the two input shaft middle bearings 13 and is inserted on the planetary gear assembly. The output shaft end bearing 11 and the output shaft end The connecting rod 10 is sequentially set on the output shaft 20 from the output end to the input end of the output shaft 20. ...

specific Embodiment approach 2

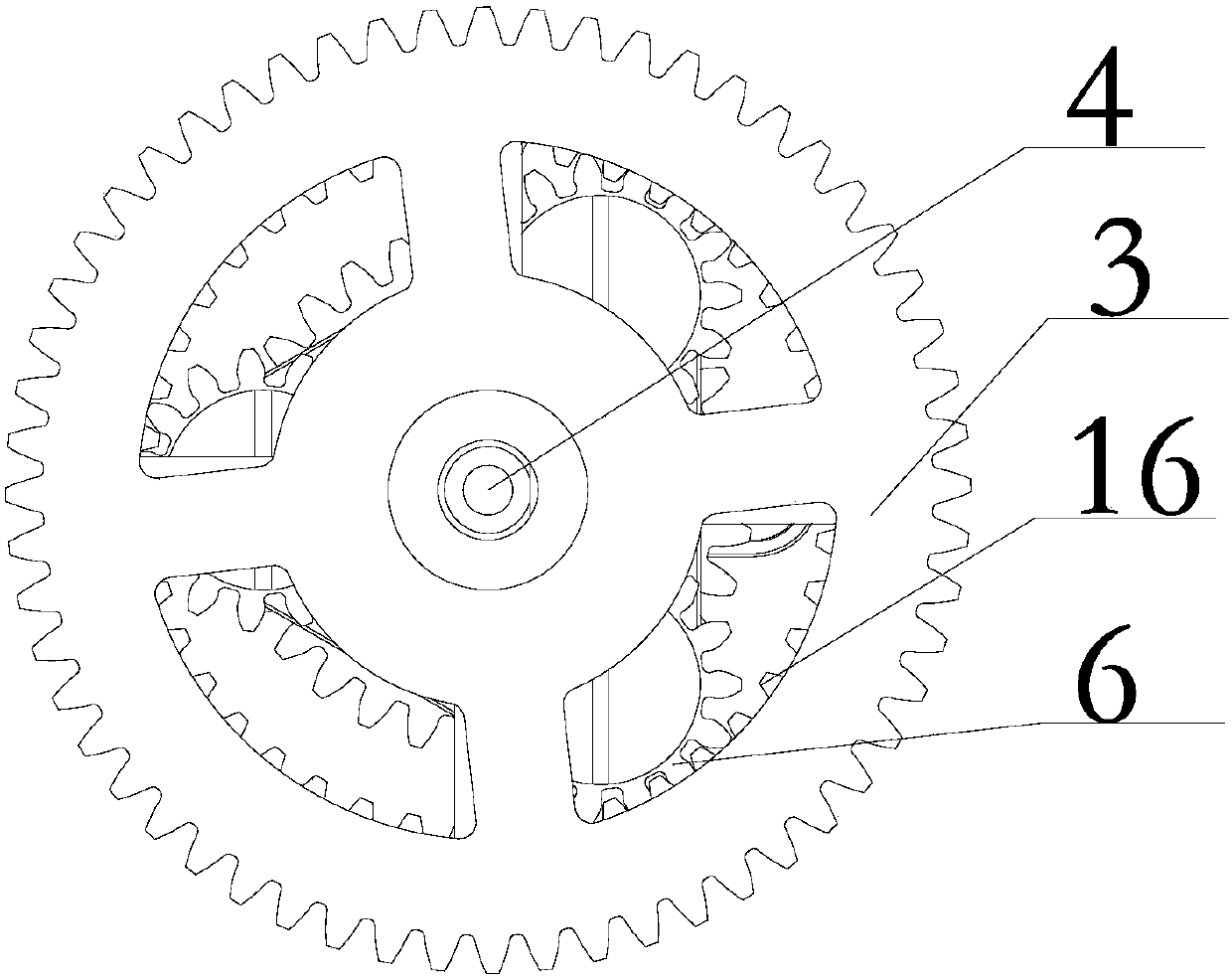

[0011] Specific implementation mode two: combination Figure 1-Figure 4 Describe this embodiment, the dual-input micro-integrated differential planetary gear described in this embodiment, the planetary gear assembly includes a planetary carrier 9, a sun gear 14, a ring gear carrier 15, an inner ring gear 16, a gear carrier 17 and Three planetary gear assemblies, the ring gear frame 15 and the gear frame 17 are relatively fixedly installed on both ends of the inner ring gear 16, the sun gear 14 is set on the output end of the input shaft 4, and the three planetary gear assemblies are evenly distributed along the circumferential direction Set on the outer surface of the sun gear 14, the three planetary gear assemblies mesh with the teeth of the sun gear 14, the three planetary gear assemblies are arranged in the inner ring gear 16, and the three planetary gear assemblies are connected to the inner ring surface of the inner ring gear 16 The teeth mesh, and the three planetary gea...

specific Embodiment approach 3

[0012] Specific implementation mode three: combination Figure 1-Figure 4 Describe this embodiment, the dual-input micro-integrated differential planetary gear described in this embodiment, the outer circular surface of the input shaft gear 3 sleeved on the input shaft 4 to the outer circular surface of the input end of the input shaft 4 is machined with The first plane 4-1, the outer circle surface of the sun gear 14 set on the output end of the input shaft 4 is processed with a second plane 4-2, the outer circle surface of the planet carrier 9 set on the input end of the output shaft 20 is machined with a third plane 20- 1. The input shaft 4 is machined with the first plane 4-1 and the second plane 4-2. The cross-section of the input shaft 4 is "D" shaped, and the output shaft 20 is machined with the third plane 20-1. The cross section is "D" shape, the central through hole of the input shaft gear 3 is processed with a protrusion corresponding to the first plane 4-1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com