Orientated locating type electromagnetic jaw clutch device

An electromagnetic clutch, directional positioning technology, applied in magnetic drive clutches, clutches, non-mechanical drive clutches, etc., can solve the problems of poor positioning and transmission system movement, and achieve the effects of good positioning, large transmission torque and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

[0022] Embodiment: In order to achieve the above object, the technical scheme adopted in the present invention is as follows:

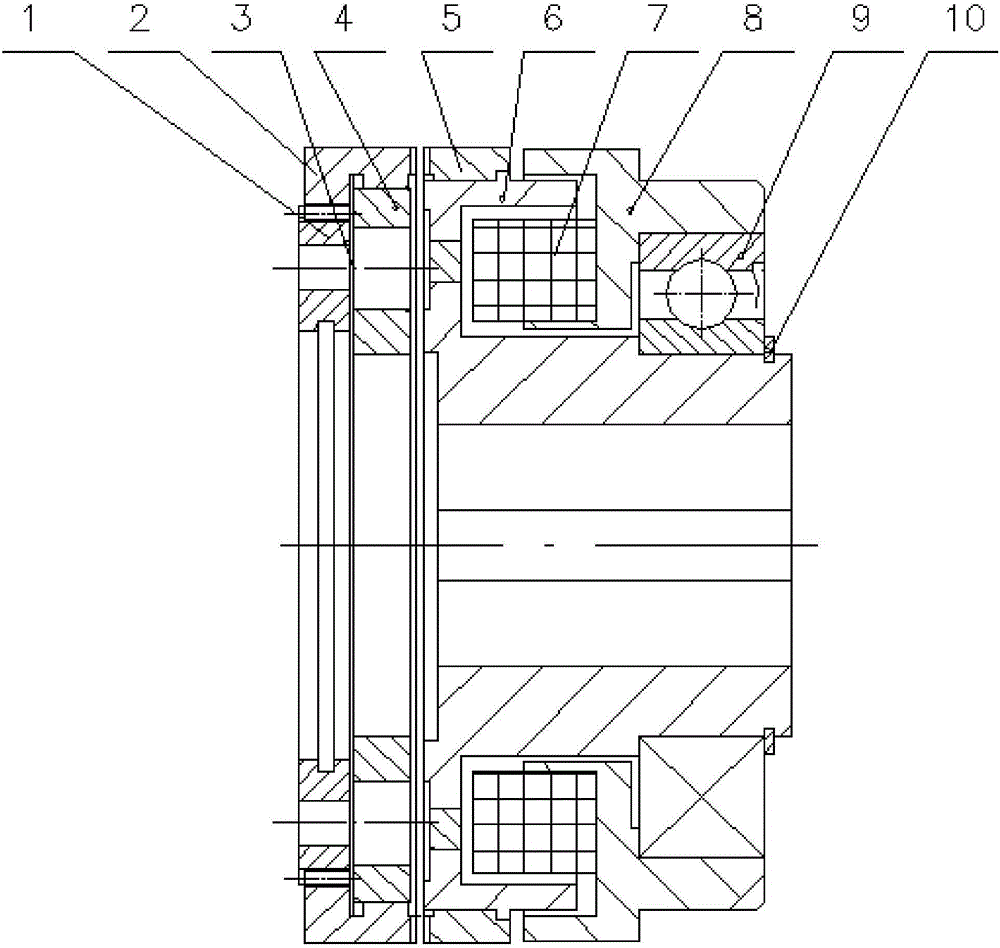

[0023] Such as figure 1 As shown, the present invention provides a directional positioning jaw type electromagnetic clutch device, including a coupling plate 1, an armature ring 2, a return spring 3, an armature 4, a baffle ring 5, a baffle 6, a coil 7, and a yoke 8. The bearing 9 and the bearing ring 10, the coil 7 are installed in the slot of the yoke 8, the armature ring 2 and the return spring piece 3 are respectively installed on the connecting plate 1, and the connecting plate 1 is connected with the driven shaft through its inner hole, The inner teeth of the armature gear ring 2 can slide on the outer teeth of the connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com