Variable-diameter drilling bit mechanism for drill stem

A drill pipe and drill bit technology, which is applied in the field of drill pipe variable diameter drill bit mechanism, can solve the problems of complex structure, large initial force on the reaming wing, uneven force on the reaming wing, etc., to improve work efficiency and simple structure Reliable, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

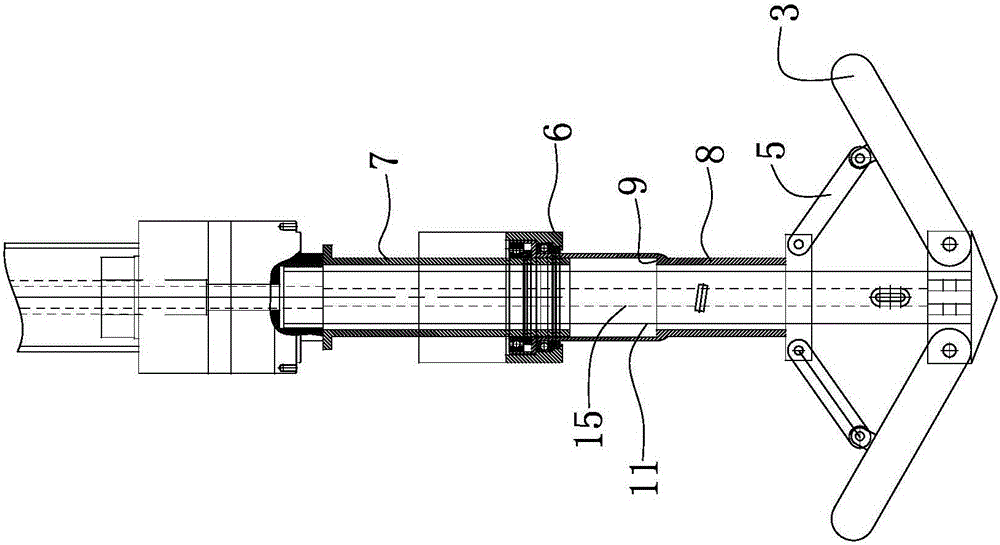

[0023] Such as figure 1 As shown, a drill rod variable diameter drill mechanism includes a drill rod assembly 1. The drill rod assembly 1 includes a drill rod 11 and a drill bit 12. There is a movable rod on the drill rod assembly 1 that can move closer to or away from the drill rod assembly. The diameter-changing mechanism 2 that moves in the direction of the axis line of 1, the diameter-changing mechanism 2 can rotate along the circumferential direction of the drill pipe assembly 1 under the power of the drill pipe assembly 1, thereby changing the diameter of the drilled hole drilled by the drill pipe assembly 1 Moreover, the rotation range of the reducing mechanism 2 gradually increases from the bottom to the top of the drill pipe assembly 1, and this structure can directly stir the loosened soil of the drill pipe assembly quickly. When the soil is not completely loosened, the resistance of the variable diameter mechanism 2 is relatively large, and the greater the stirring ...

Embodiment 2

[0032] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as figure 1 As shown, the drill pipe 11 is a hollow structure and at least one slurry outlet 14 is provided on the drill pipe 11, and a slurry delivery pipe 15 is inserted in the drill pipe 11, and the slurry output by the slurry delivery pipe 15 can Flow out from the slurry outlet 14. The outer wall of the drill pipe 11 is provided with at least one stirring mechanism 16 that is recessed into the inside of the drill pipe 11 or protrudes from the drill pipe 11. The stirring mechanism 16 mainly plays the role of stirring the slurry. When the slurry flows out from the slurry outlet 14, the slurry Located outside the drill pipe 11, the stirring mechanism 16 stirs the slurry so that the slurry is evenly distributed around the drill pipe 11. Those skilled in the art should understand that the shape and size of the stirring mechanism 16 are not limite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com