Fire extinguish wall

A fire extinguishing wall and fire extinguishing material technology, applied in the field of disaster prevention and mitigation of building structures, can solve problems such as large secondary water damage in non-fire areas, need to replace, electric shock casualties, etc., to ensure property safety, fast response, and fire extinguishing effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

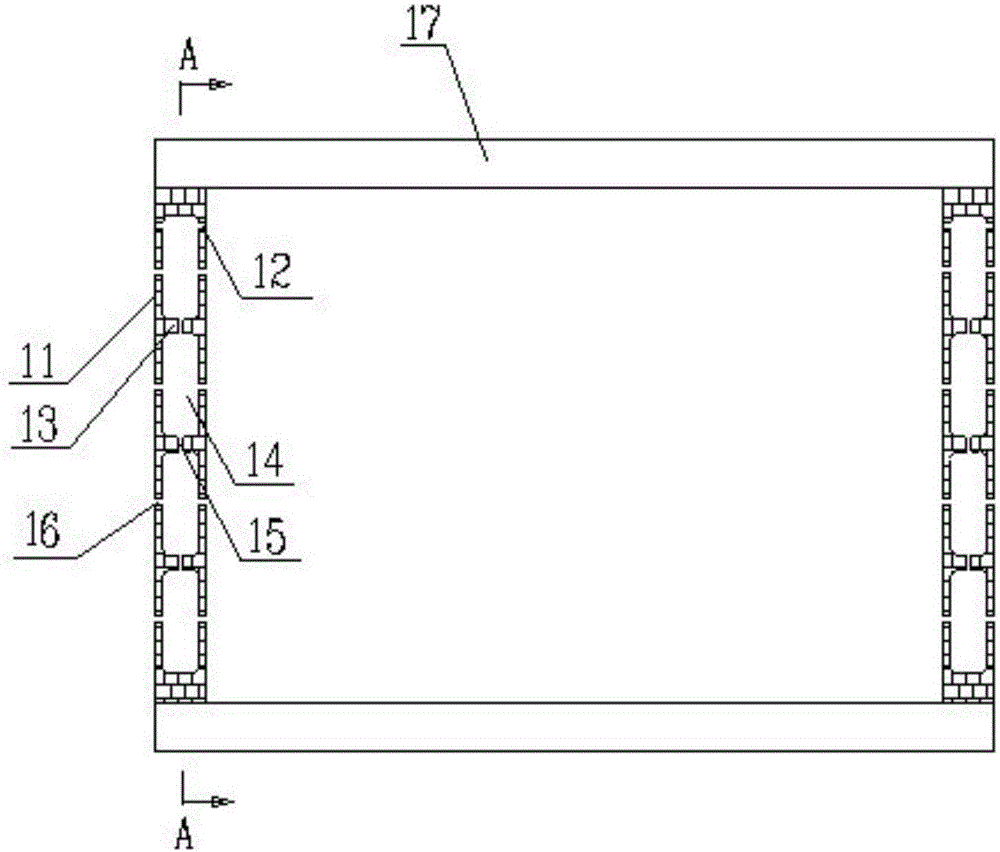

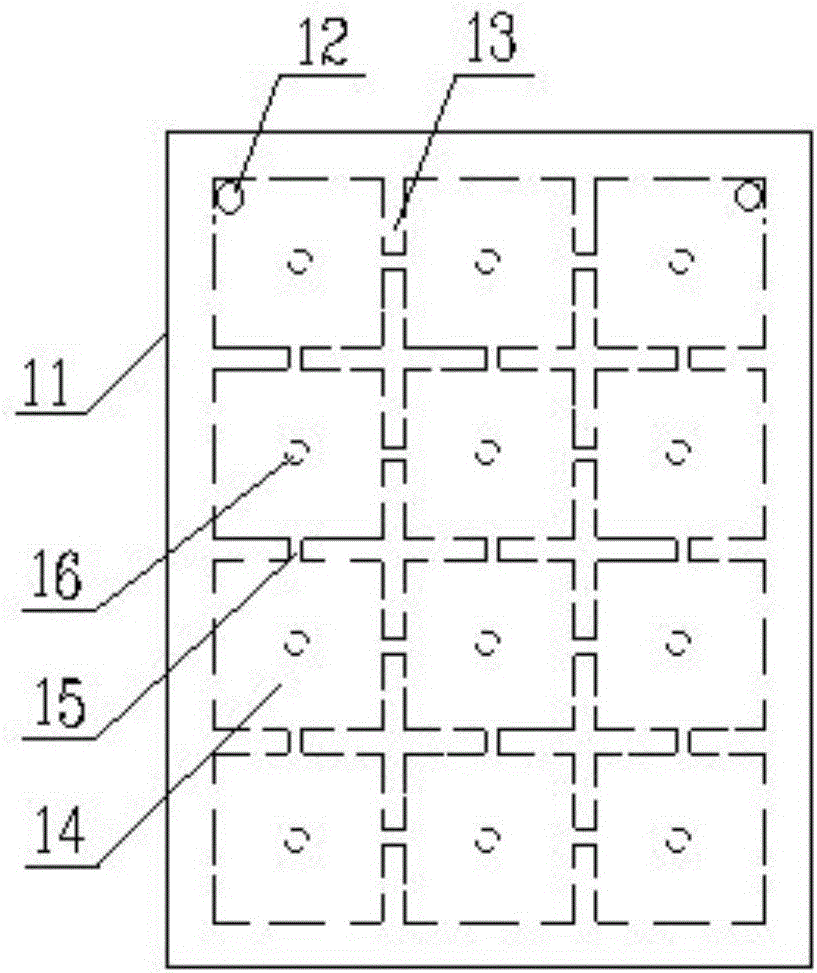

[0015] Such as Figure 1 to Figure 4 The shown fire extinguishing wall includes a wall 11, the wall 11 is arranged between two floor slabs 17, a plurality of cavities 14 are arranged in the wall 11, column gratings 13 are arranged between the cavities 14, and through The feeding channels 15 are connected to each other, each cavity 14 is equipped with fire extinguishing materials, the upper part of the wall 11 is provided with a feeding port 12, and the two sides of the wall 11 are provided with discharge ports 16; the fire extinguishing control system is installed on the wall 11 The fire extinguishing control system includes a processor, a fire extinguishing alarm device, and a plurality of smoke sensors and temperature sensors distributed on both sides of the wall 11. The smoke sensor, temperature sensor and fire extinguishing alarm device are connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com