Improved multi-speed electronic let-off system

An electronic warp let-off and improved technology, applied in the field of warp knitting machines, can solve the problems of inaccurate control of the slave axis speed, prone to horizontal stripes, etc., to save communication costs, improve follow-up response performance, and improve horizontal stripes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

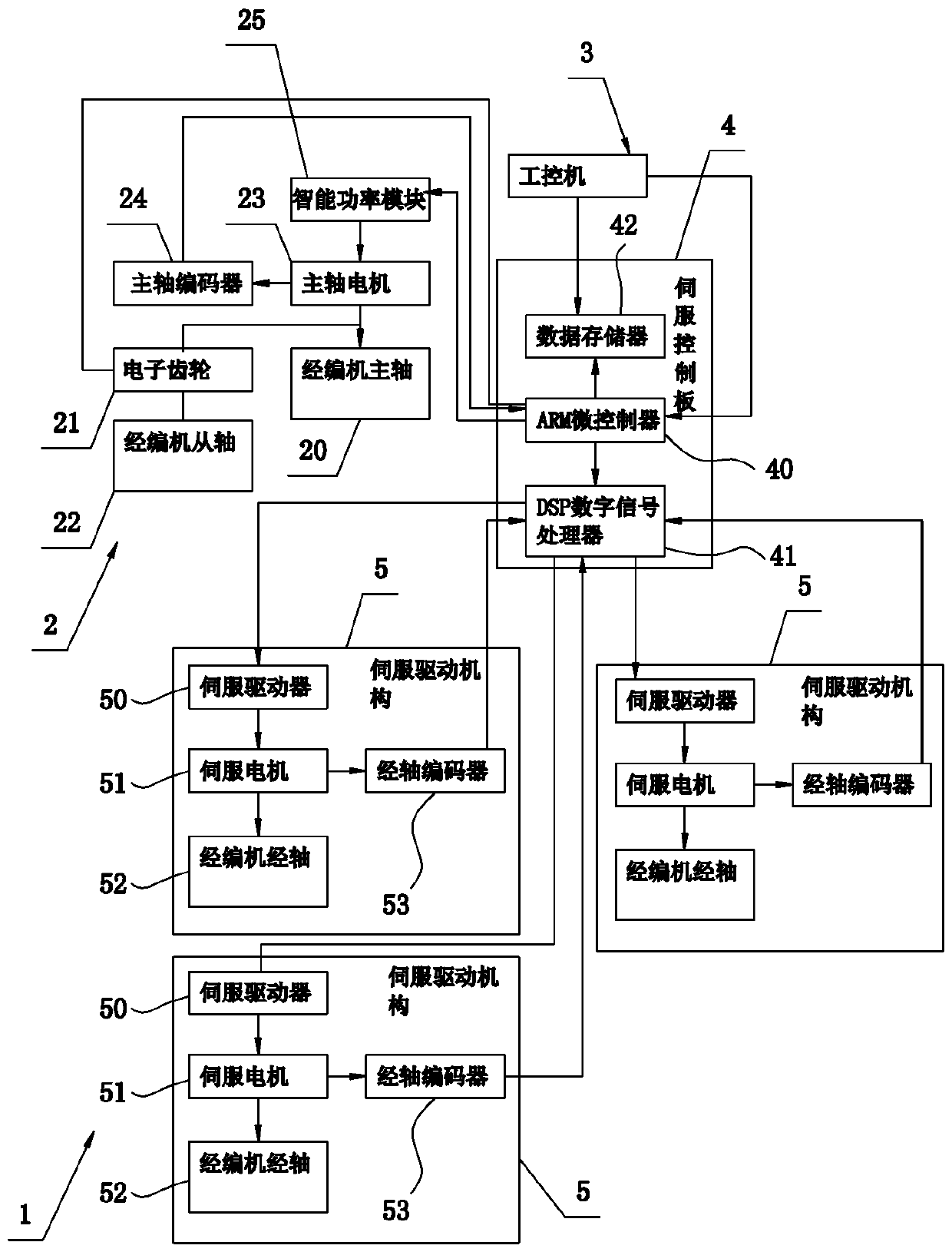

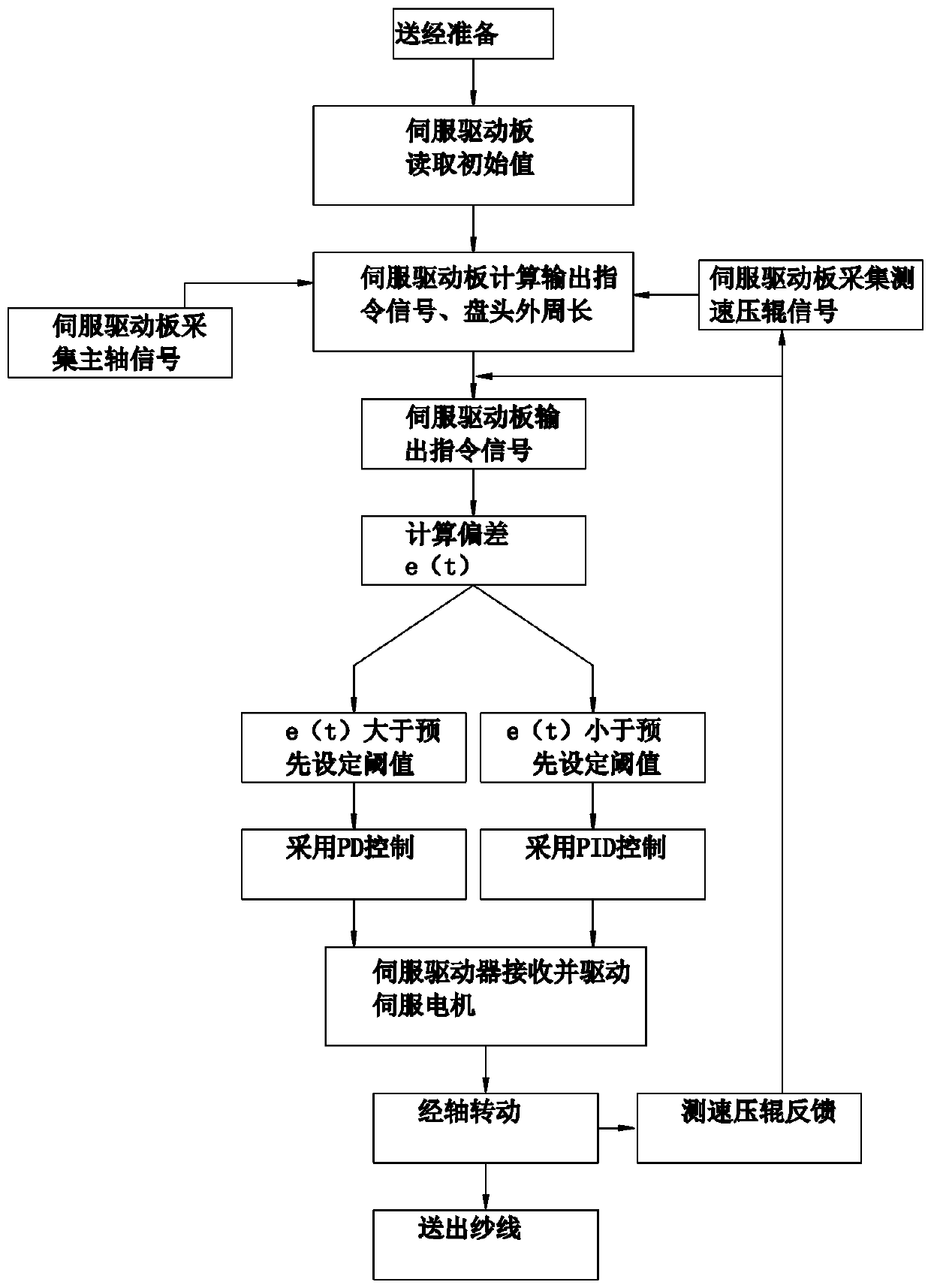

[0023] refer to figure 1 . An improved multi-speed electronic warp let-off system 1, comprising a warp knitting machine main mechanism 2, an industrial computer 3, a servo control board 4 and a plurality of servo drive mechanisms 5 for controlling the warp shaft rotation of the warp knitting machine, the warp knitting machine The machine body mechanism 2 comprises a main shaft 20, an electronic gear 21, a slave shaft 22, a main shaft motor 23, a main shaft encoder 24 and a main shaft motor 23 control circuit for detecting the main shaft motor 23 operating states, and the main shaft motor The torque output end of 23 is respectively connected with the main shaft 20 and the electronic gear 21, and the torque output end of the electronic gear 21 is connected with the slave shaft 22; the enabling end of the main shaft motor control circuit is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com