Improved semi-cone seed crystal chuck

A technology of seed crystal chuck and chuck, which is applied in the direction of crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems that do not meet the actual use requirements, affect work efficiency, waste production resources, etc., and achieve easy observation, The effect of improving production efficiency and ensuring air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

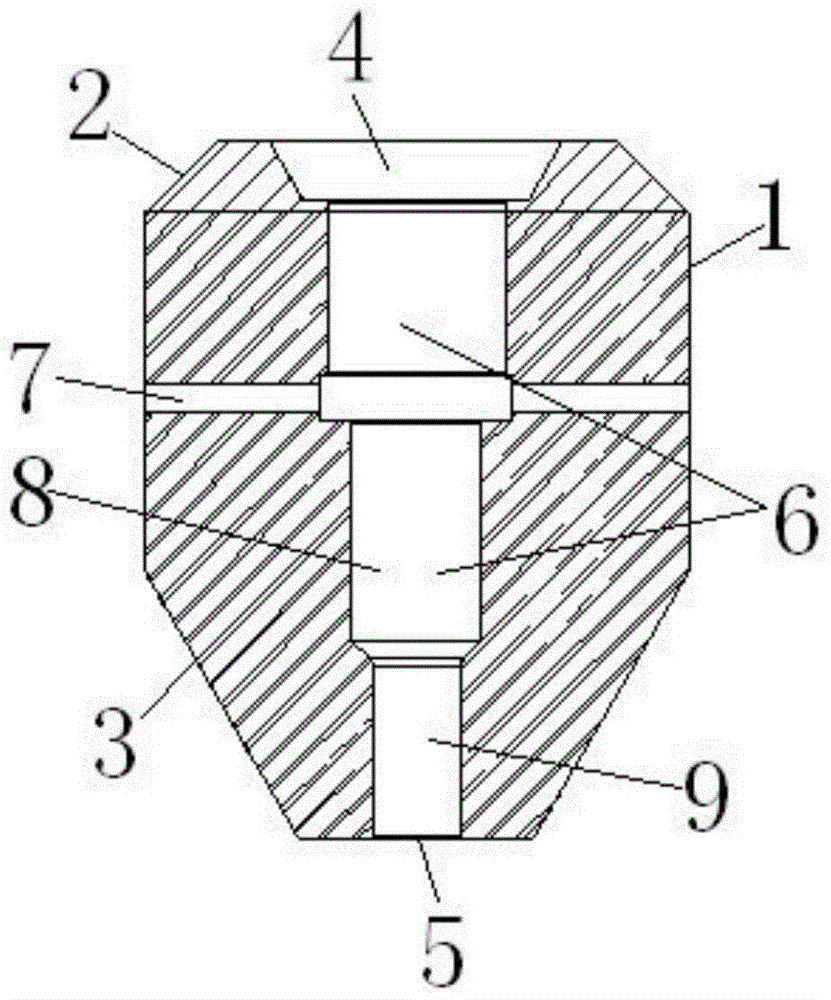

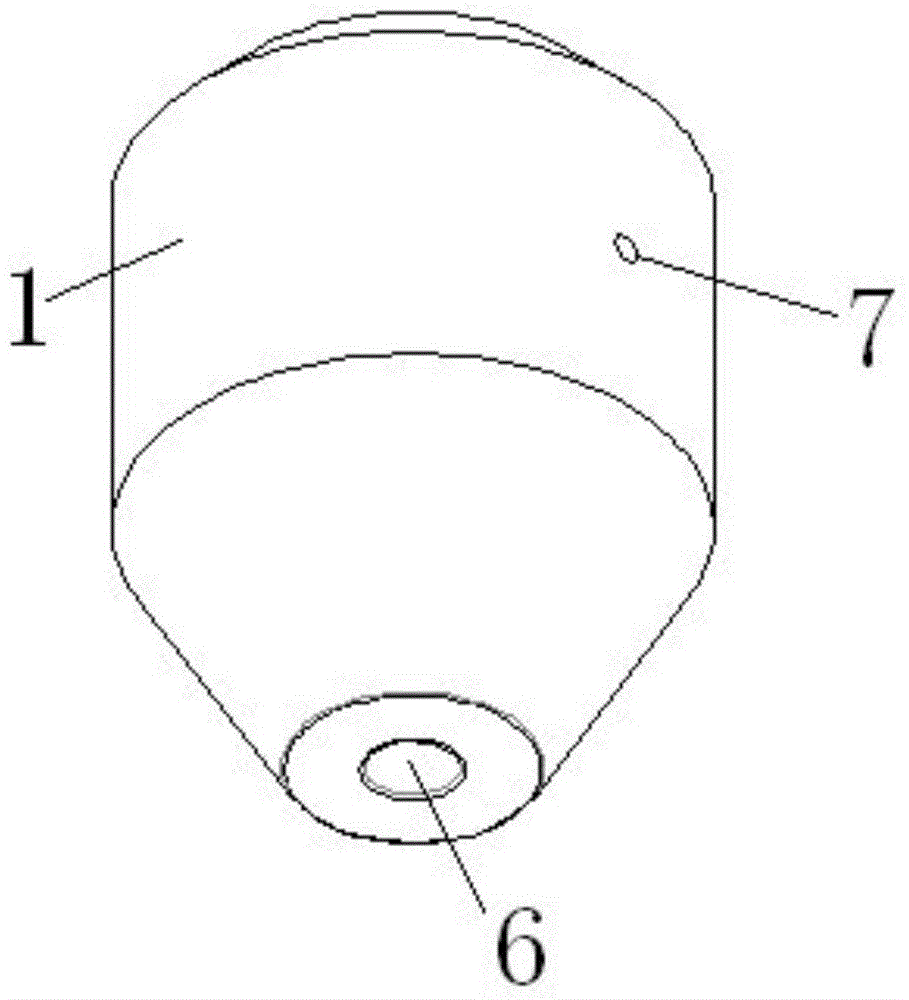

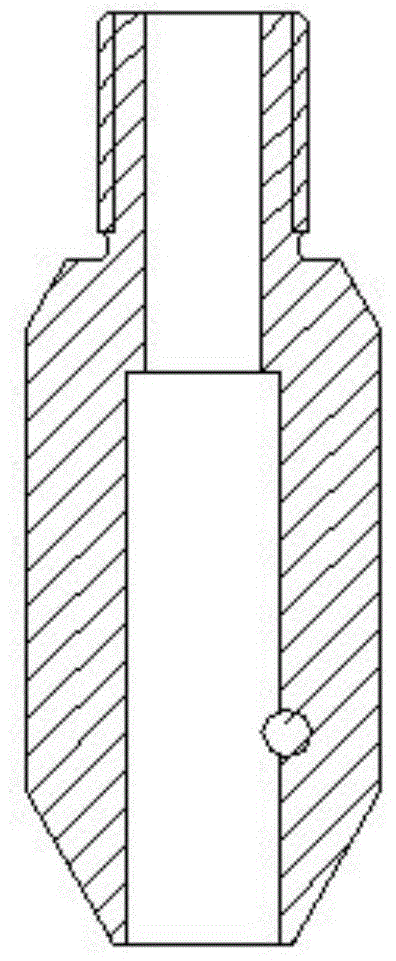

[0013] Such as figure 1 and figure 2 As shown, an improved semi-cone seed crystal chuck according to the present invention includes a chuck body 1, an airflow guide slope 2 is arranged on the upper part of the chuck body 1, and an airflow guiding slope 2 is arranged on the lower part of the chuck body 1. There is a crystal pulling observation slope 3, a chuck connection belt installation hole 4 is provided in the middle of the chuck body 1 from top to bottom, and a seed crystal positioning hole 5 is provided below the chuck connection belt installation hole 4, which form The positioning channel 6 is installed, and a ventilating channel 7 is provided at the connection between the chuck connection belt installation hole 4 and the seed crystal positioning hole 5, and the chuck connection belt installation hole 4 and the seed crystal positioning hole 5 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com