Preparation method of ion exchange resin substrate and activated carbon integrated electrode for capacitive desalination

An ion exchange resin, activated carbon technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of weak contact, the influence of membrane capacitance desalination performance, high mass transfer resistance and contact resistance, etc., and achieve energy consumption. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

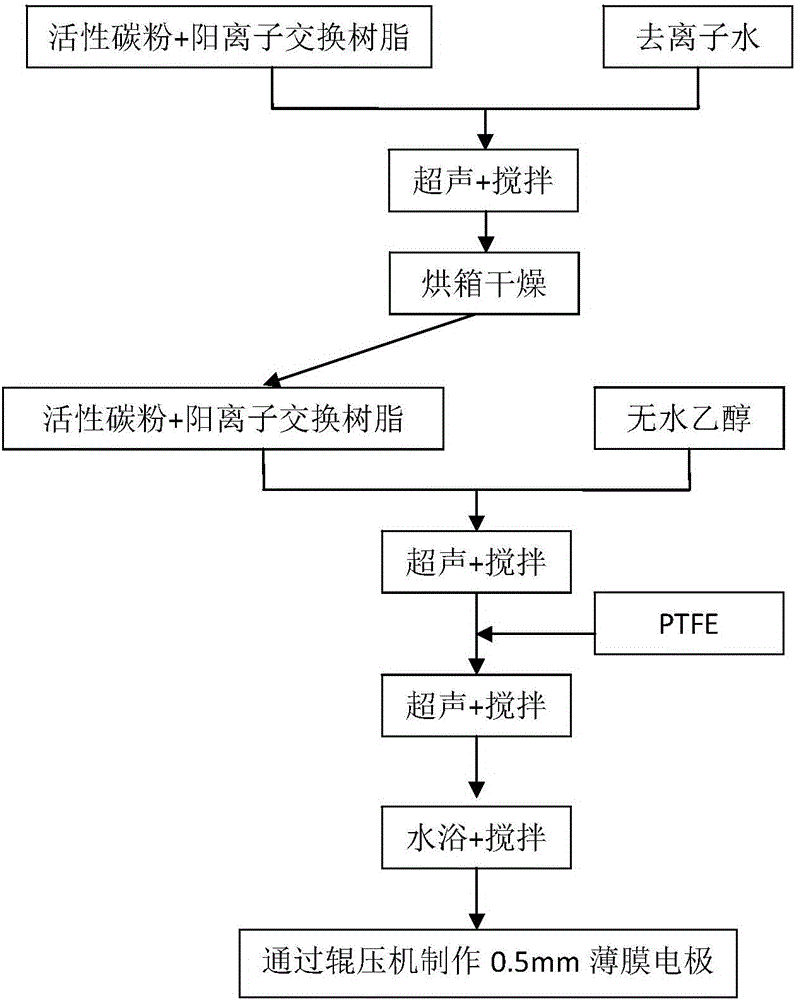

[0026] The ion exchange resin-supercapacitor activated carbon-PTFE monolithic composite electrode for capacitive desalination comprises a cathode and an anode, and the steps of the preparation method are as follows:

[0027] cathode:

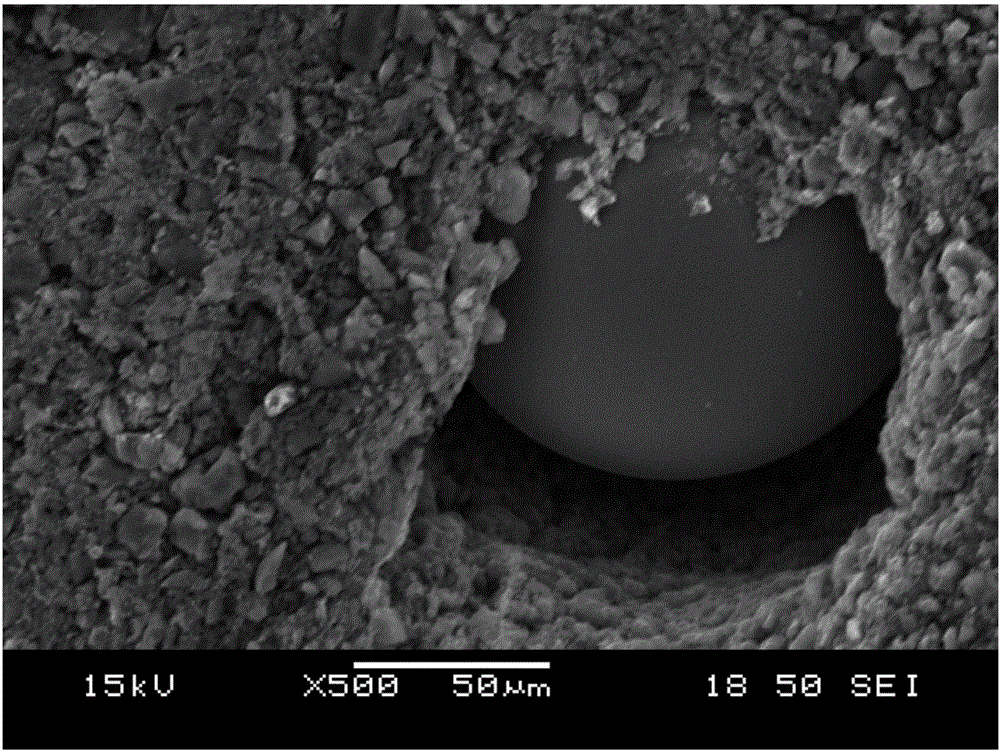

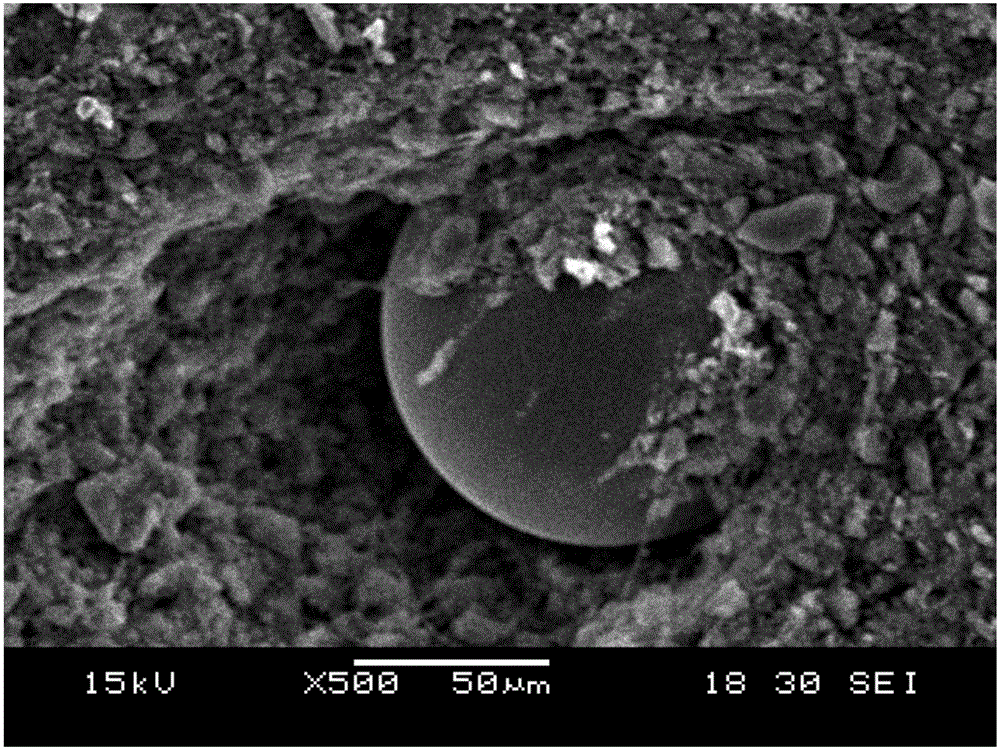

[0028] 1) The supercapacitor activated carbon (model SPC-02S Fujian Xinsen Carbon Industry Co., Ltd.) has a specific surface area of 1500m 2 / g) and cation exchange resin (model 005×7) (Nankai University Resin Co., Ltd.) were ultrasonically cleaned and dried in deionized water, and then mixed with absolute ethanol and ultrasonically stirred for 15-30min to make the conductive carbon The black is fully dispersed and dissolved in absolute ethanol. Under the condition of ultrasonic stirring, the polytetrafluoroethylene emulsion is added dropwise, and then ultrasonically stirred for 15-30min. The results of cathode scanning electron microscopy are as follows: figure 1 As shown, the preparation process is as follows figure 2 shown.

[0029] 2) ...

Embodiment 1

[0041]The ion exchange resin-supercapacitor activated carbon-PTFE monolithic composite electrode for capacitive desalination comprises a cathode and an anode, and the steps of the preparation method are as follows:

[0042] cathode

[0043] 1) Take 6g of activated carbon powder and 1g of cation exchange resin, mix the two in deionized water, ultrasonically clean and dry them, mix with 42g of absolute ethanol, and stir ultrasonically for 15 minutes to fully disperse and dissolve the carbon powder in absolute ethanol In the process, under the condition of ultrasonic stirring, add polytetrafluoroethylene emulsion dropwise, and then ultrasonically stir for 15 minutes;

[0044] 2) Stir the above mixed substance in a water bath at 70°C for 1h30min, add absolute ethanol to make it into a micelle, and roll it continuously on a roller press until it is pressed into a thin sheet to obtain a cation exchange resin-activated carbon Electrode CER-AC-1;

[0045] anode

[0046] 1) Take 6g ...

Embodiment 2

[0050] The ion exchange resin-supercapacitor activated carbon-PTFE monolithic composite electrode for capacitive desalination comprises a cathode and an anode, and the steps of the preparation method are as follows:

[0051] cathode

[0052] 1) Take 5g of activated carbon powder and 1g of cation exchange resin, mix them in deionized water and ultrasonically clean and dry them, mix them with 48g of absolute ethanol, and stir ultrasonically for 25min to fully disperse and dissolve the carbon powder in absolute ethanol In the process, under the condition of ultrasonic stirring, add polytetrafluoroethylene emulsion dropwise, and then ultrasonically stir for 25 minutes;

[0053] 2) Stir the above mixed substance for 2 hours in a water bath at 80°C, add absolute ethanol to make it into a micelle, and roll it continuously on a roller press until it is pressed into a thin sheet to obtain a cation exchange resin-activated carbon Electrode CER-AC-2;

[0054] anode

[0055] 1) Take 5g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com