Water-gas replacement type underwater equipment auxiliary installation device and method

A technology for underwater equipment and installation devices, which is applied to underwater operation equipment, transportation and packaging, ships, etc. It can solve the problems of high cost, inconvenient transportation of underwater equipment, and large bearing capacity of installation cables, and achieve low cost and weather protection. The effect of low condition requirements and not easy to be affected by bad weather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

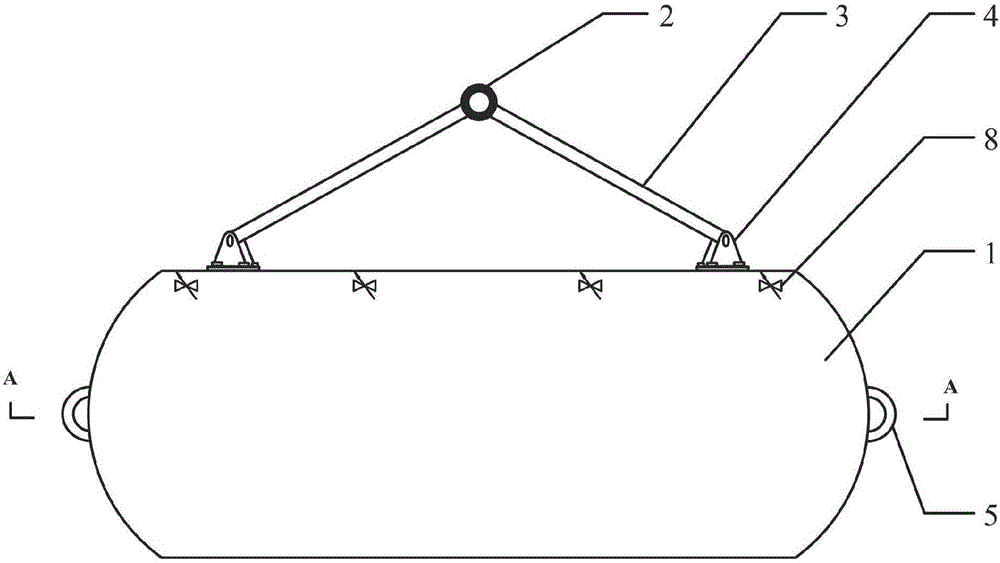

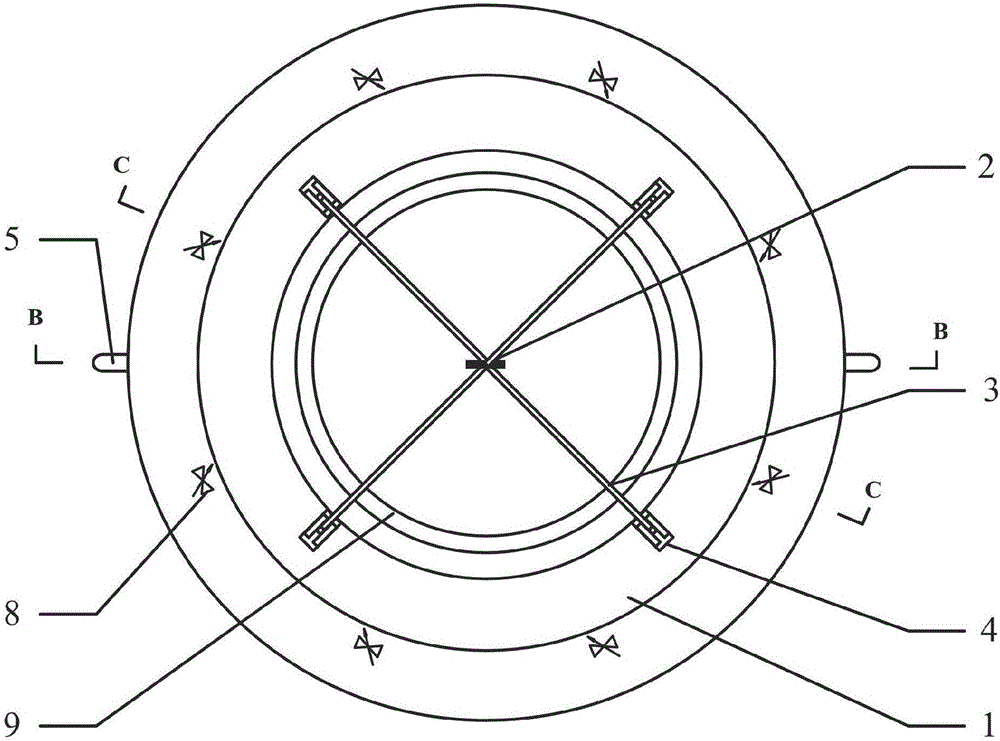

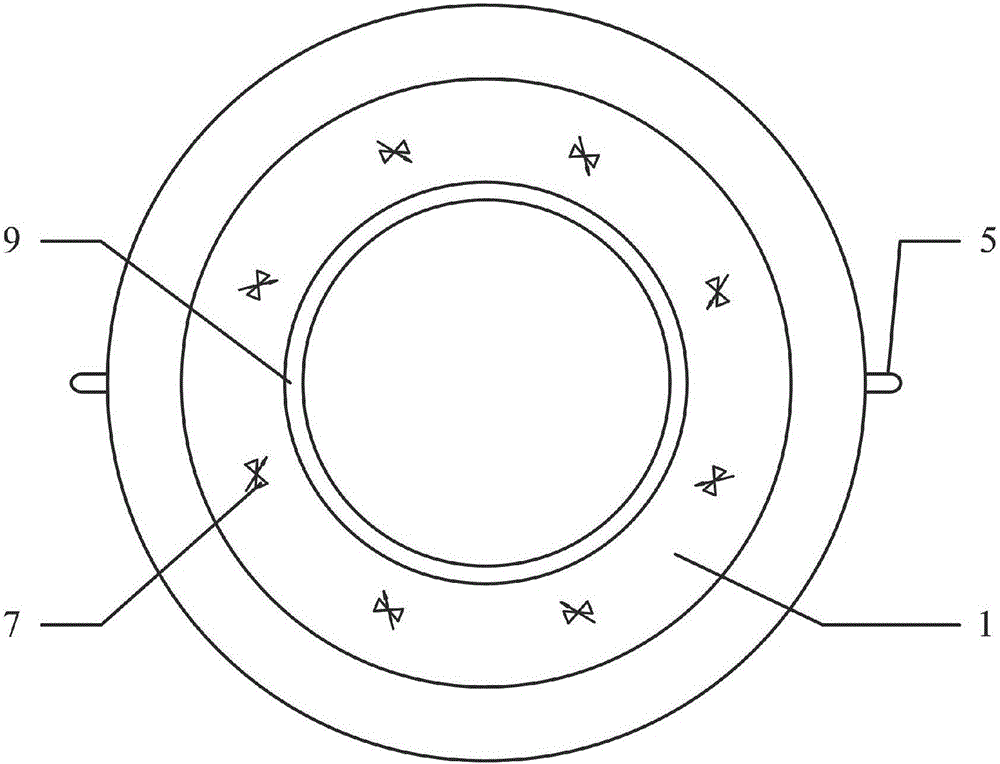

[0034] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the water-gas replacement underwater auxiliary installation device includes: main body 1, hinge support 4, bracket 3, bracket lifting ring 11, lifting lug 5, ballast tank 6, water inlet valve 7, exhaust valve 8, rubber Washer 9.

[0035] The main body 1 is drum-shaped as a whole, and the outer wall 32 of the main body is smooth and streamlined; the inner wall 31 of the main body is cylindrical, and the top is chamfered; the main body 1 is made of steel and can withstand deep water pressure; the top surface of the main body 1 is provided with four hinge supports 4. The four hinge supports 4 are evenly distributed along the circumference, each hinge support 4 is connected with a bracket 3 , and the tops of all the supports 3 are connected with the bracket rings 2 , which are used to connect the load-bearing hooks 33 .

[0036] The outer wall 32 of the main body 1 is provided with two l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com