Iron part spraying tool equipment

A technology of tooling equipment and iron parts, which is applied in the field of iron parts spraying tooling equipment, can solve the problems of low process efficiency, high labor intensity of workers, and poor consistency, and achieve high work efficiency, good consistency and stability, and low operating intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

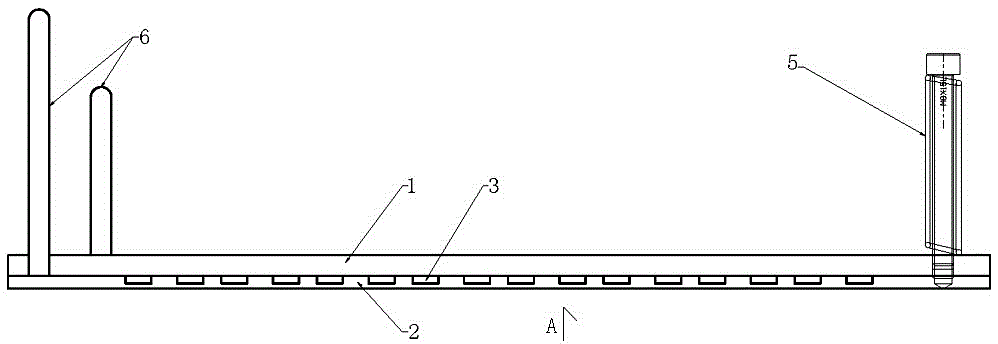

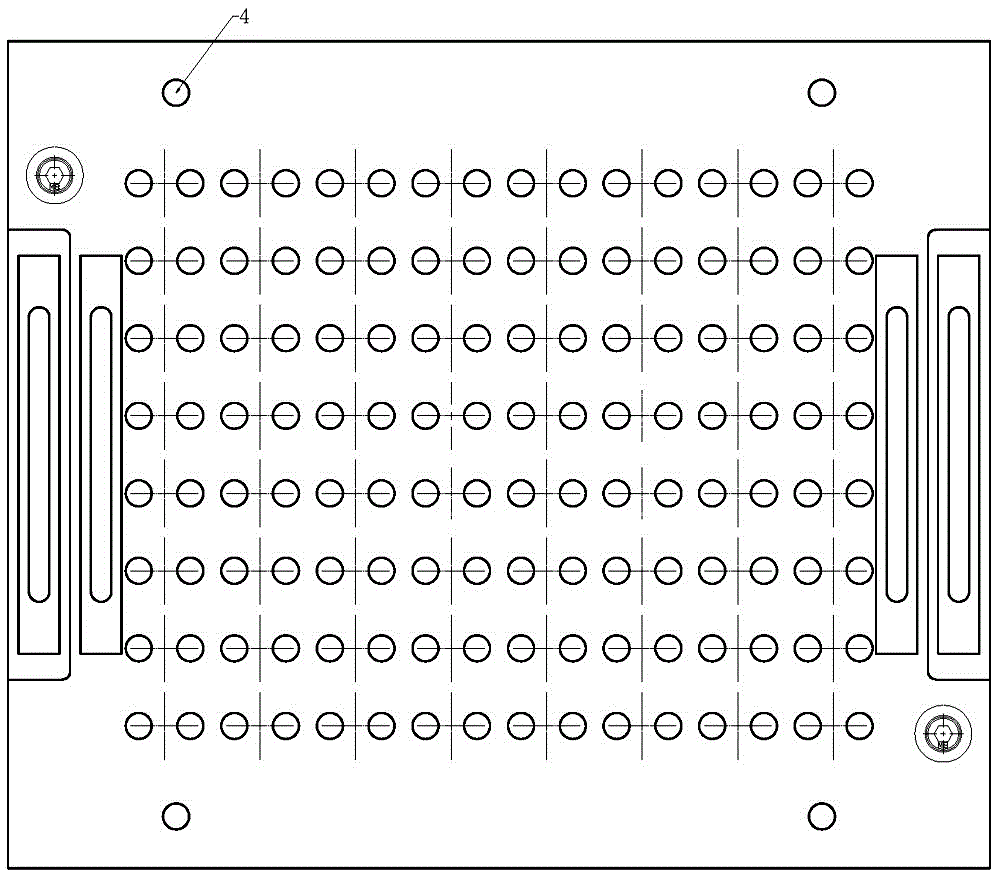

[0012] Example: figure 1 , 2 As shown, a kind of pre-processing tooling equipment for iron parts according to the present invention is used for the pre-treatment process of metal parts exposed on one side. It includes an upper plate 1 and a lower plate 2. Close, utilize the guide post positioning hole 4 to make the upper and lower plates can be fixed and positioned during work, place a fixed strong magnet 3 in the blind hole above the lower plate, and install two handles 6 that are respectively fixed on the upper and lower plates and have a certain height difference in the left and right sides.

[0013] When in use, place the metal plate on the upper plate at one time when the upper and lower plates are pressed together. At this time, the strong magnet of the lower plate will firmly absorb the iron metal plate through the upper plate, and then put the The tooling of the metal plate is put into the automatic sandblasting machine or automatic spraying machine for automatic proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com