Textile size storage device

A storage device and technology for textile pulp, applied in the textile field, can solve problems such as textile pulp agglomeration, achieve the effect of preventing pulp agglomeration and promoting the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

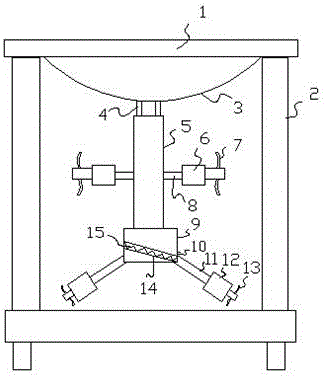

[0017] Such as figure 1 , figure 2 As shown, the structure of this kind of textile slurry storage device includes a tank body 2 and an upper cover 1. The bottom surface of the upper cover 1 is provided with a downwardly protruding diversion surface 3, and the bottom of the diversion surface 3 is passed through the hanging The rod 4 is vertically fixed with a cylinder 5, the bottom of the cylinder 5 is provided with a heating box 9, the bottom of the heating box 9 is provided with a slant plate 14, and the slant plate 14 is provided with a heating wire 15, and the heating wire 15 and The external power line (not shown in the figure) is electrically connected; the heating box 9 on the bottom side of the inclined plate 14 is provided with a liquid discharge port 10 . When in use, water vapor can condense i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com