Efficient tail gas automatic purifying device

A technology for automatic purification and exhaust gas, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agents, etc., can solve the problems of limited effect, separation, and inability to separate solid particles, and achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

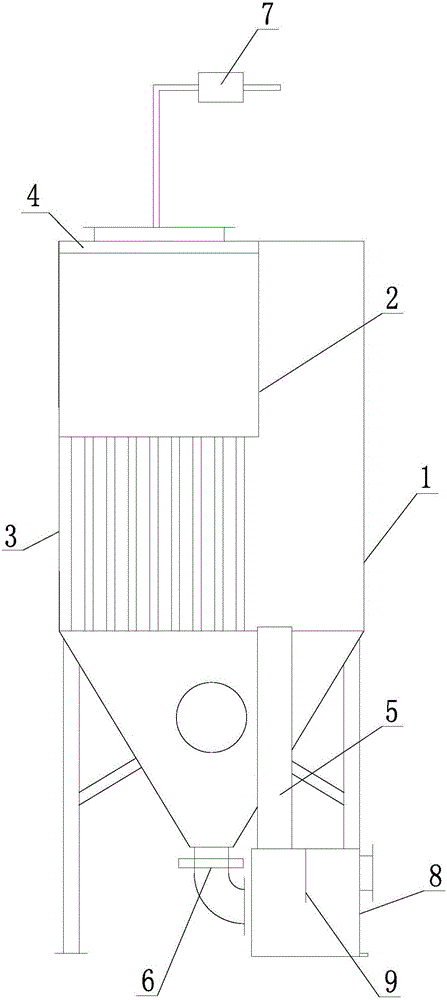

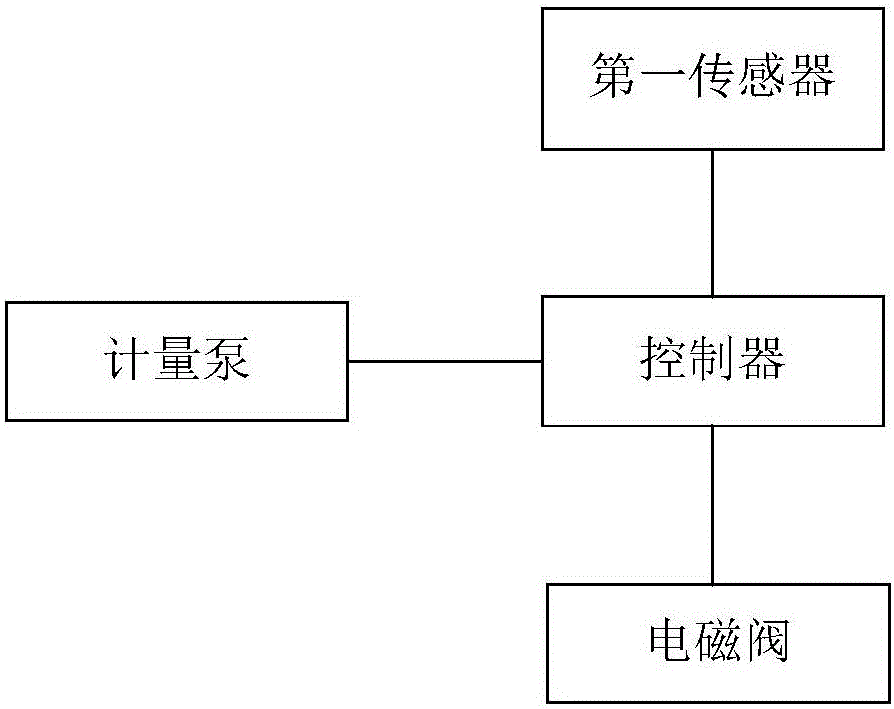

[0029] like figure 1 as shown, figure 1 It is a structural schematic diagram of the present invention. It includes a box body 1, a clapboard 2, a purifier 3, a shower 4, an overflow pipe 5, an impurity sensor, a solenoid valve 6, a controller and a metering pump 7.

[0030] The lower end of the box 1 has a V-shaped structure, and the tip of the V-shaped structure is downward; the purifier 3 is installed in the box 1, and the outer edge of its upper end is connected with the partition 2, which divides the space in the box 1 into spraying The shower chamber, the precipitation chamber and the gas outflow chamber; the spray chamber and the gas outflow chamber are all located above the purifier 3, and the sedimentation chamber is surrounded by a V-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com