Water cooled type motor cycle engine water pump and its actuating mechanism

A technology for engines and motorcycles, which is applied in the direction of engine components, engine cooling, machines/engines, etc. It can solve the problems of changing the pump water volume of the engine and not being able to adjust the transmission ratio, and achieve high pump water efficiency, improve pump water efficiency, and seal Reliable and Guaranteed Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

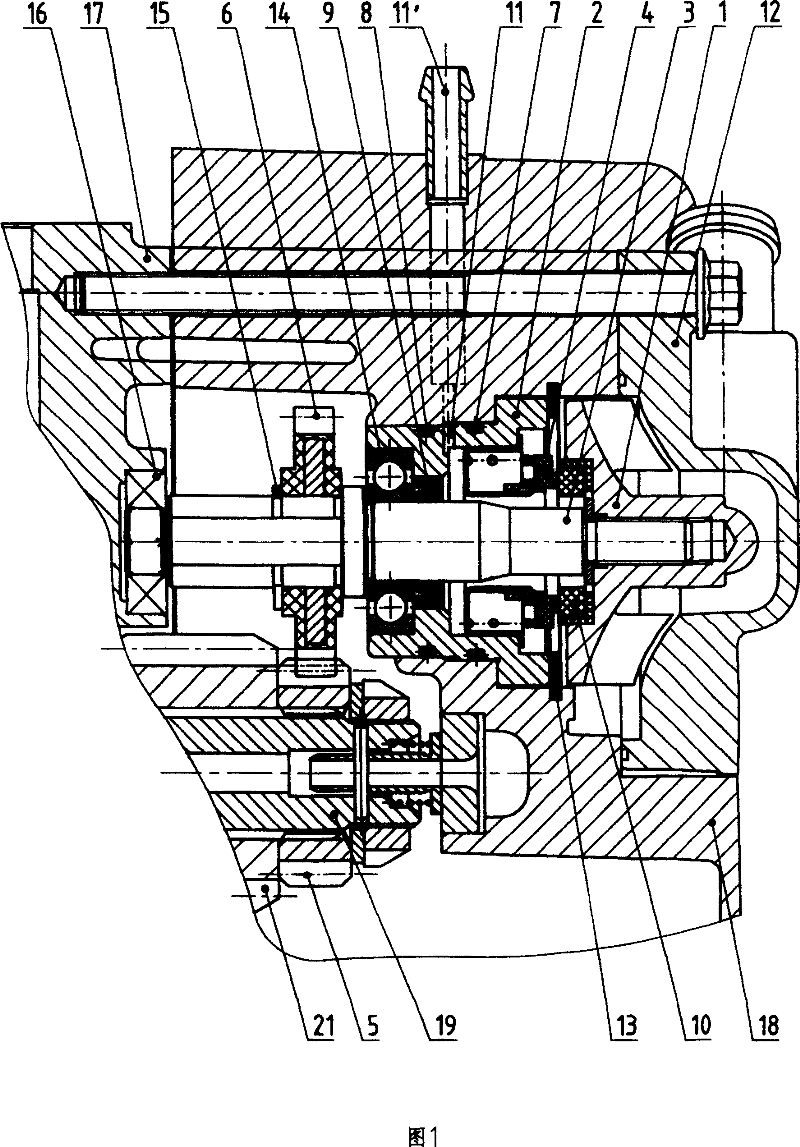

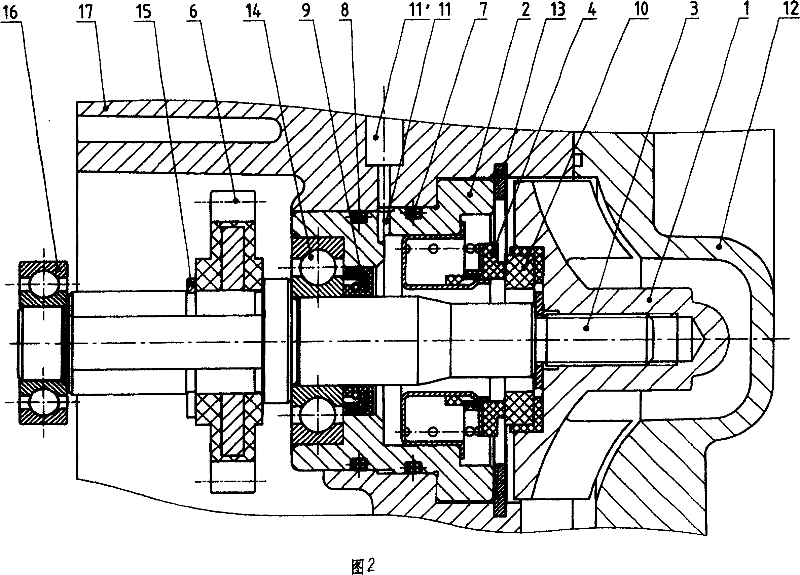

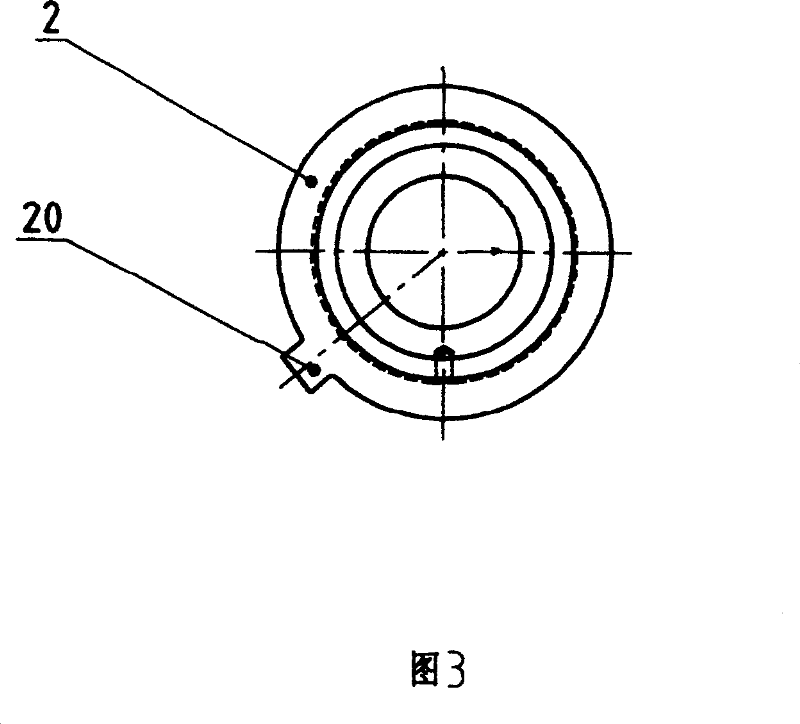

[0015] Please see Fig. 1: the present invention includes a water pump and the starting mechanism of the water pump, wherein the water pump is a water-cooled integral water pump, which mainly consists of a water pump cover 12, an impeller 1, a water pump body 2, a water pump shaft 3, and a mechanical water seal static ring Combination 4, sealing ring 7, sealing ring 8, oil seal 9, mechanical water seal moving ring 10, axial positioning ring 13, bearing 14, bearing 16, it is contained in the crankcase cover 18; the starting mechanism of the water pump Mainly be made up of crankcase 17, engine crankshaft 19, water pump driving gear 5, driving gear 21 on the former crankshaft, driven gear 6 and elastic retaining ring 15 etc., it is connected with water pump by a pair of gear meshing.

[0016] As shown in Figure 1: a bearing 14, an oil seal 9, and a static ring combination 4 of a mechanical water seal are installed in the water pump body 2, and the water pump shaft 3 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com