Float-type sludge scraping and suction system, and sludge scraping and suction operation method

A mud system and floating technology, which is applied in the field of secondary sedimentation tank cleaning equipment, can solve the problems of easy scratching of the bottom of the pool by the mud scraper, rail gnawing and derailment of the mud scraper, and high maintenance costs, achieving simple structure and convenient maintenance , Low maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

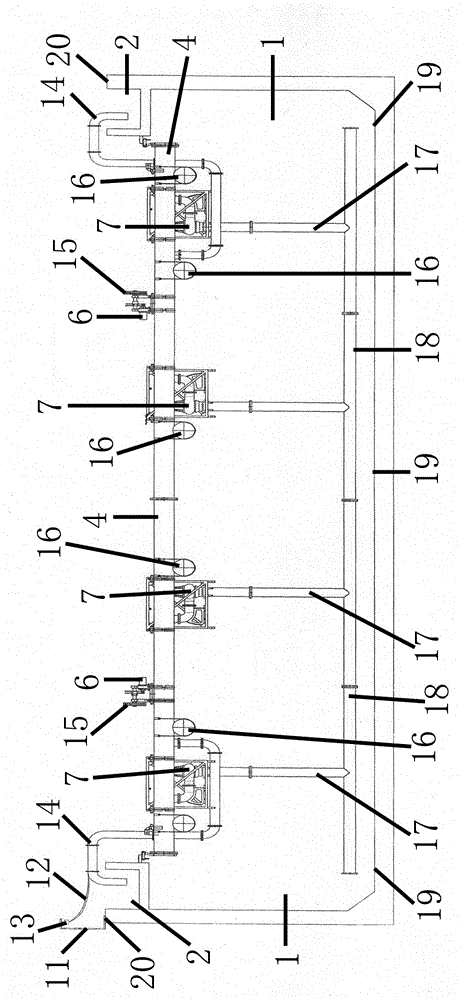

Embodiment 1

[0025] It consists of the secondary settling tank (1) tank body, pontoon driving (4) and mud suction and scraping device (19). (4) In the secondary settling tank (1), the suction and scraping device (19) is driven to reciprocate, and the suction and scraping device (19) sucks and scrapes the sludge deposited on the bottom (19) of the secondary settling tank (1), and the secondary settling The tank (1) is in the form of a rectangular box as a whole, and return channels (2) are set on both sides of the pool body of the secondary sedimentation tank (1) (20). Set on the side, the return channel (2) recovers the sludge deposited on the bottom (19) of the secondary settling tank (1), and discharges it to the outside of the secondary settling tank (1).

[0026] The pool edge (20) on one side of the secondary settling tank (1) is provided with cable slideway supports (11) equidistantly along the pool edge (20), at least four cable slideway supports (11) are arranged, and the cable sli...

Embodiment 2

[0029] The pontoon driving (4), the pontoon driving (4) is composed of a limiter (3), a travel drive (6), a traction wheel (15) and a buoy (16), the pontoon driving (4) is rectangular as a whole, and the pontoon driving ( 4) Install buoys (16) on the lower part, at least 6 buoys (16), the buoys (16) are vacuum barrel-shaped, and the buoys (16) support the floating boat driving (4) to float in the secondary settling tank (1) , the four corners of the floating boat driving (4) are installed with stoppers (3), the stoppers (3) limit the floating boat driving (4) to reciprocate within the scope of the secondary settling tank (1), and the floating boat driving (4) is installed Set travel drive device (6), install at least 2 travel drive devices (6), travel drive device (6) corresponds to traction steel cable (5) respectively, travel drive device (6) drives traction wheel through speed reducer ( 15), the traction wheel (15) is opposite to the traction steel cable (5), the traction s...

Embodiment 3

[0031] The mud suction and scraping device (21) is composed of a submersible pump (7), a mud discharge pipe (8), a discharge pipe (14), a drainage pipe (17) and a mud suction pipe (18), and the lower part of the travel drive device (6) is set Suction mud scraping device (21), submersible pump (7) is installed on the suction mud scraping device (21), at least 4, the water inlet of every submersible pump (7) is connected with drainage pipe (17), and drainage pipe ( One end of 17) is connected to the water inlet of the submersible pump (7), and the other end of the drainage pipe (17) is connected to the suction pipe (18). The mud pipe (18) is connected with the drainage pipe (17) of each submersible pump (7). 18) Set up a mud suction hole to suck the sludge deposited on the bottom of the pool (19). The outlet of each submersible pump (7) is connected to the mud discharge pipe (8), and the mud discharge pipe (8) is installed on the floating boat. (4) The upper part, the mud disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com