Mower

A lawn mower and engine technology, applied in the mechanical field, can solve the problems of short friction wheel structure, small driving torque, short friction wheel structure life, etc., and achieve the effect of reasonable structure, ingenious design, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

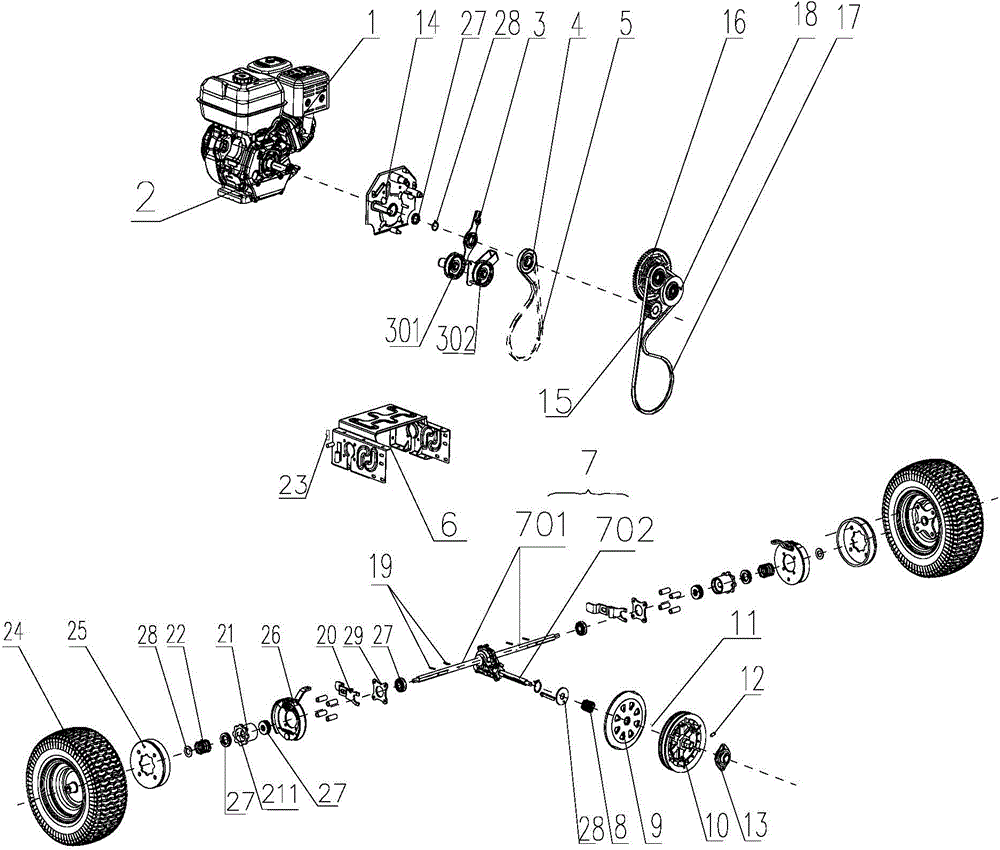

[0022] The lawnmower of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 As shown, the mower of the present invention includes an engine 1 , a first transmission assembly, a second transmission assembly, a mounting plate 6 , a mounting plate 2 14 and wheels 24 . Described first transmission assembly comprises crankshaft 2, pressing device support 3, driving wheel one 4, belt one 5, gear 15, pulley two 16, belt two 17 and retreat guide wheel 18, and pressing device support 3 is provided with advance Compression device 301 and retreat compression device 302. The second transmission assembly includes a worm gear 7, a driven wheel device, a pin 12, a ball bearing 13, an elastic pin 19, a clutch wrench 20, a clutch 21, an elastic element 22, a fixed pin 23, a brake hub 25, and a brake disc 26. The worm gear 7 has a differential speed adjustment, which can make the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com