Thermal ageing testing apparatus and using method thereof

A testing device and thermal aging technology, applied in the direction of measurement device, single semiconductor device testing, measurement of electricity, etc., can solve the problems of inability to achieve real-time monitoring, inability to improve detection efficiency, and a small number of detections, achieving a large number of tests, Fast and time-saving testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0030] Example.

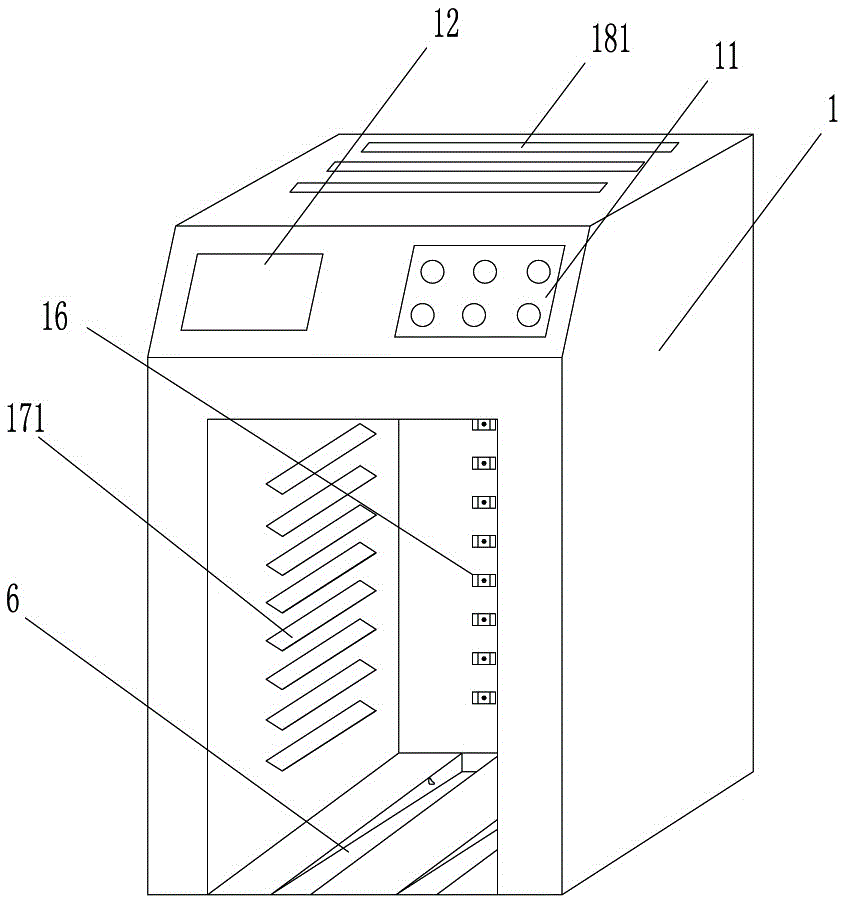

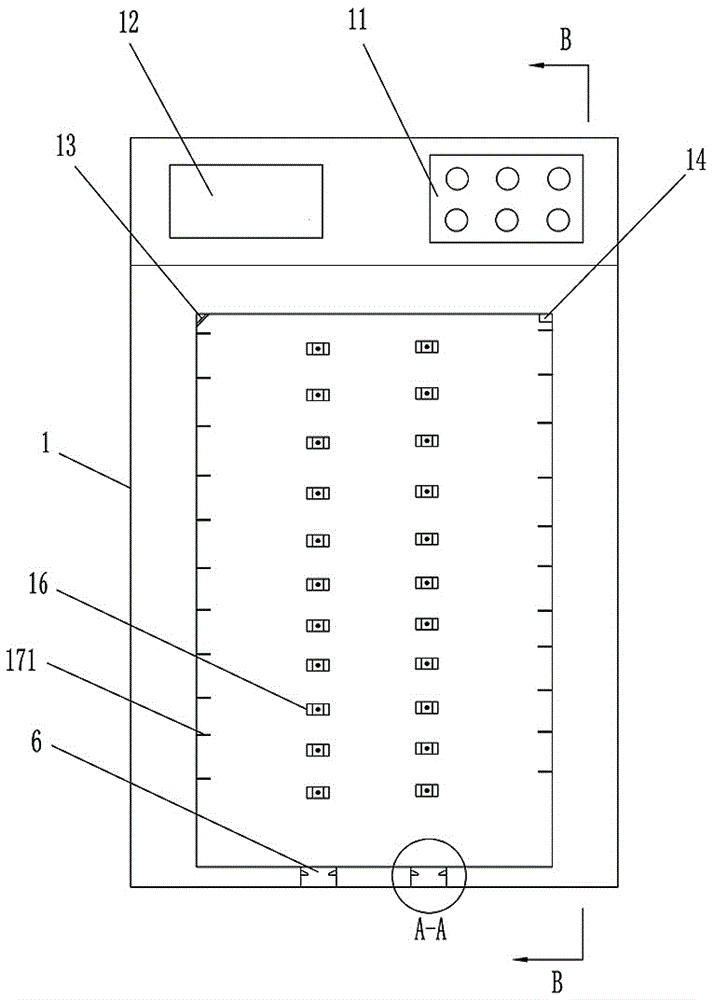

[0031] see Figure 1-Figure 9 , the present invention includes a test box 1 and a feeding device 2, an operation panel 11 is provided outside the test box 1, and a liquid crystal display 12 is provided next to the operation panel 11. A camera 13 and a temperature sensor 14 are arranged in the test box 1 . An air duct 15 is arranged in the two side walls of the test box 1, and a heating device 3 and a fan 4 are arranged at the lower end of the test box 1. The heating device 3 is connected with the air duct 15, and the fan 4 is installed on one side of the heating device 3. The test box 1 is provided with multiple groups of vertically arranged power supply card slots 16, and the test box inner wall on both sides of each group of power supply card slots 16 is provided with an air inlet 17, the test box top is provided with an air outlet 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com