A device and method for online measurement of gas injection crude oil volume coefficient and solubility

A technology of volume coefficient and solubility, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of bulky, high instrument prices, and high prices, and achieve the effect of improving automation, high precision, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

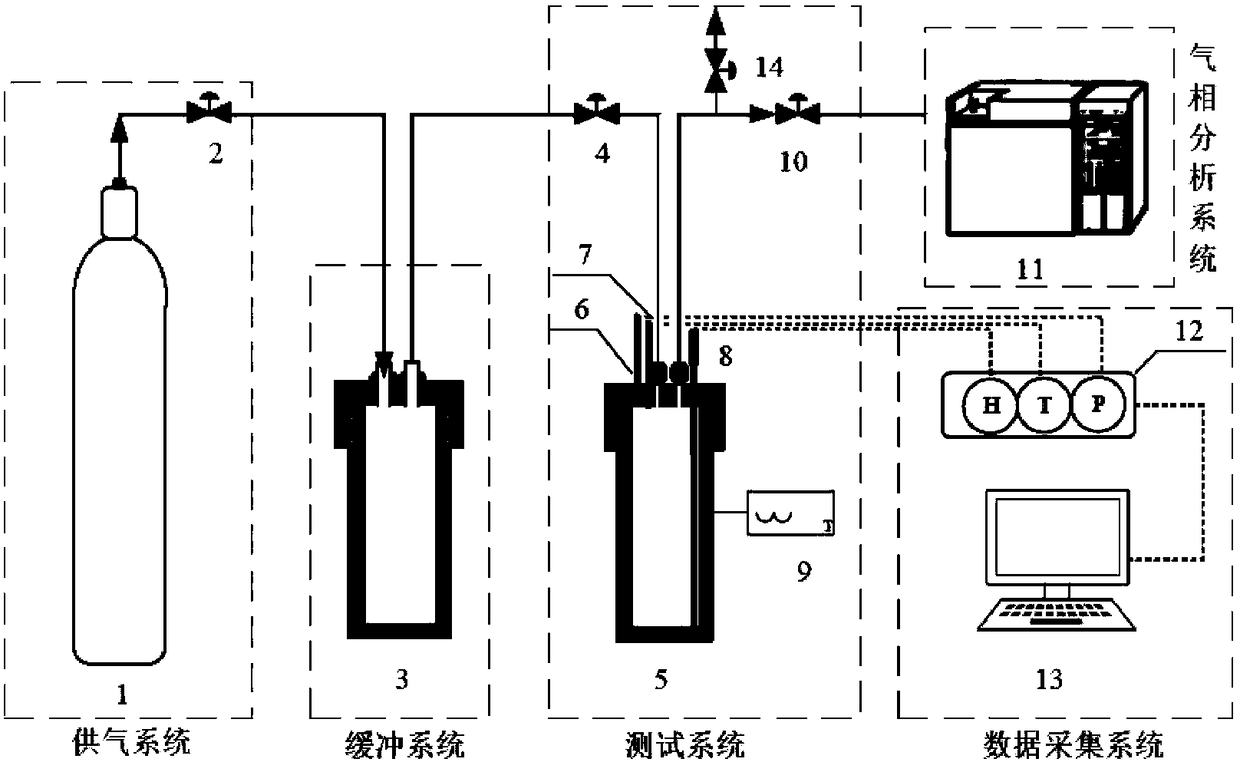

[0041] like figure 1 As shown, a device for online measurement of gas injection crude oil volume coefficient and solubility includes a gas supply system, a buffer system, a test system, a gas phase analysis system and a data acquisition system, the gas supply system includes a gas cylinder 1; the buffer system Including a high-pressure buffer container 3, the input port of the buffer container 3 is connected to the gas cylinder 1 through a pipeline with a first gate valve 2, and the output port is connected to the input port of a high-pressure reaction vessel 5 through a pipeline with a second gate valve 4; The test system includes a high-pressure reaction vessel 5, a temperature controller 9 arranged on the high-pressure reaction vessel 5; the gas phase analysis system includes a gas chromatograph 11 for component analysis of the gas composition in the high-pressure reaction vessel 5; The shown data acquisition system includes a computer 13, a data collector 12 and a temperat...

Embodiment 2

[0048] In this example, CO 2Taking gas as an example, the volume of the high-pressure reactor 5 in the test (PVT) system is known to be 380.06mL (the diameter of the high-pressure reactor 5 is D=4.65cm, and the height H=22.38cm). The test temperature is 60°C, and the oil samples are taken from Block Qi 40 of Liaohe Oilfield.

[0049] Measure about 200mL of dehydrated crude oil and inject it into the high-pressure reactor, and the liquid level sensor 8 shows the oil sample height H 1 =11.78cm, after calculation, the volume of crude oil is V 1 =200.05mL, the rest is CO 2 The volume of the gas, ie V 11 = 180.01mL; After purging the gas to discharge the air in the high-pressure reactor, inject CO at room temperature 2 Gas to a given pressure, P 1 =3.00MPa, gas temperature is T 1 =298.15K, the gas component is pure CO 2 Gas, under the temperature and pressure conditions at this time, the compressibility factor Z 1 =0.8186394; raise the temperature to the test temperature of...

Embodiment 3

[0052] In this embodiment, the simulated flue gas (expressed in volume mole fraction, where CO 2 30%, N 2 70%) as an example, the volume of the high pressure reactor 5 in the test (PVT) system is known to be 380.06mL (high pressure reactor 5 diameter D=4.65cm, height H=22.38cm), and the test temperature is 60°C.

[0053] Measure about 200mL of dehydrated crude oil and inject it into the high-pressure reactor, and the liquid level sensor 8 shows the oil sample height H 1 =11.78cm, after calculation, the volume of crude oil is V 1= 200.05mL, the rest is the volume of simulated flue gas, namely V 11 =180.01mL; After purging the gas to discharge the air in the high-pressure reactor, inject the simulated flue gas at room temperature to a given pressure, which is P 1 =3.00MPa, gas temperature is T 1 =298.15K, the composition of simulated flue gas obtained by gas chromatography analysis is CO 2 30.5%, N 2 is 69.5%, under the conditions of temperature and pressure at this time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com