Online measurement reconstruction method for large-scale cylinder profile based on parallel error separation method

An error separation and large-scale technology, applied in the direction of mechanical counter/curvature measurement, etc., can solve the problem that the geometric center cannot be extracted correctly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

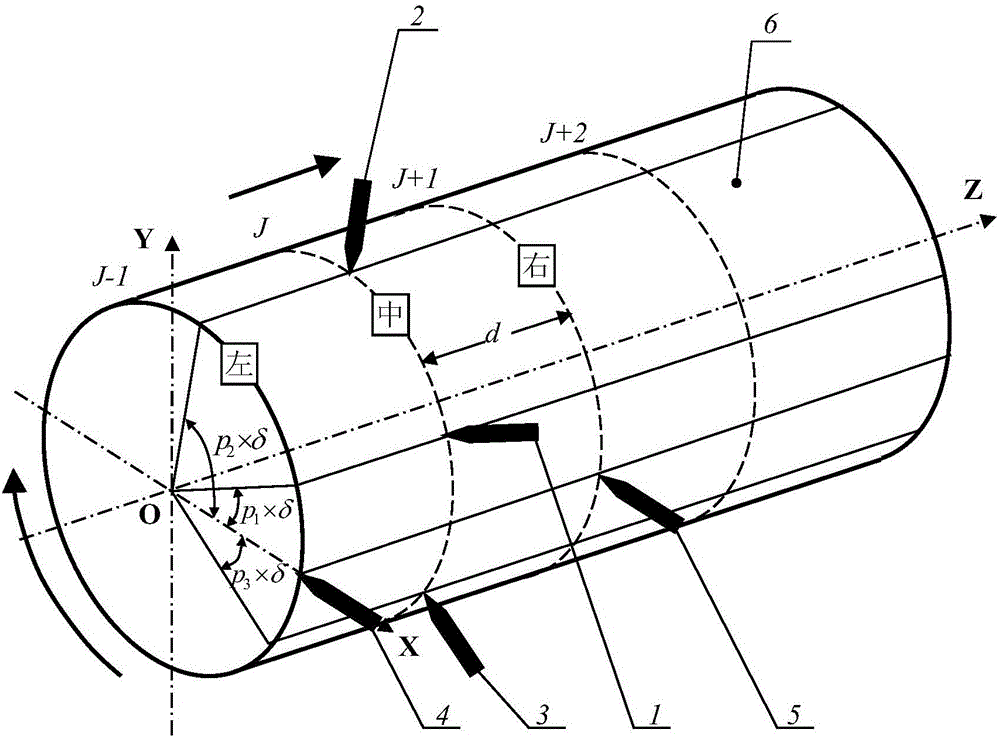

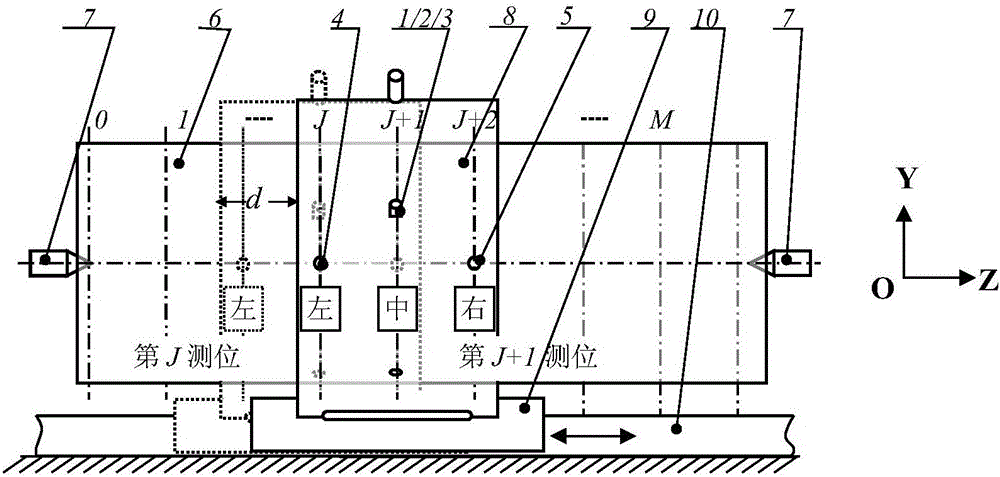

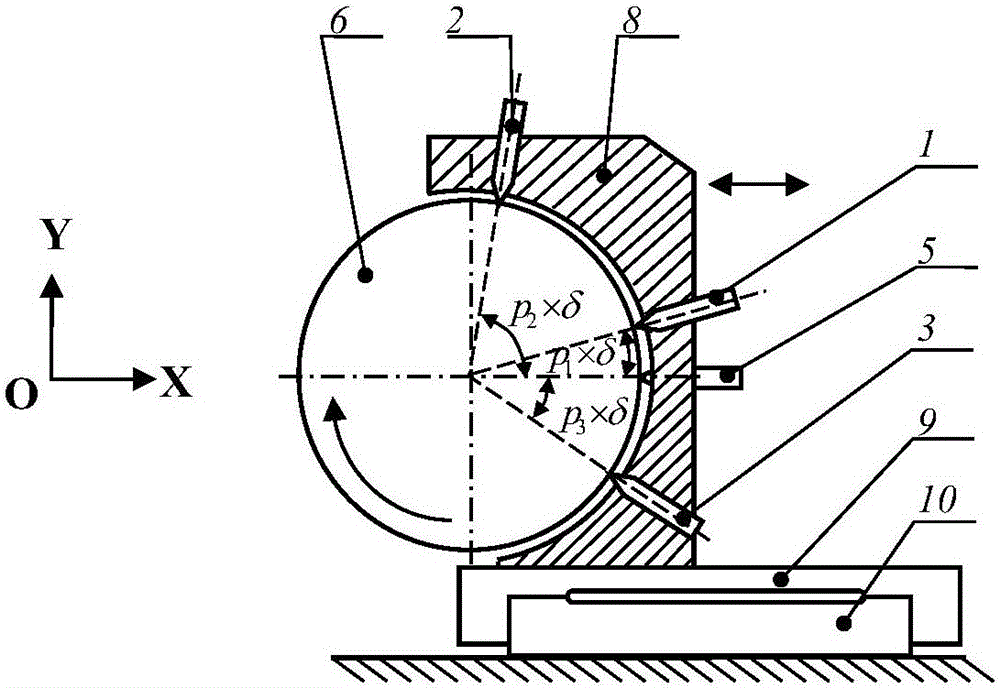

Embodiment Construction

[0051] In this example, if figure 2 As shown, the measurement frame 8 can move in the X-Z direction under the joint support of the Z guide rail 10 and the X guide rail 9; the supporting shaft system 7 supports and drives the measured body 6 to rotate; the Z guide rail 10 is parallel to the axial direction of the measured body 6 . At the beginning of the measurement, the measuring frame 8 approaches the measured body 6 along the X direction under the support of the X guide rail 9, and moves along the Z direction under the support of the Z guide rail 10 to enter the position measurement, and the moving step distance of the measuring frame 8 along the Z direction is d . In the specific implementation, an online measurement and reconstruction method of a large cylindrical profile based on the parallel error separation method extracts the roundness and relative radius of each measurement section of the measured object 6 through three-point roundness error separation; Parallel er...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com