A gas valve closing method

A technology of gas valves and levers, applied in valve details, valve devices, valve operation/release devices, etc., can solve problems such as difficult frequent verification, failure, poor memory, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

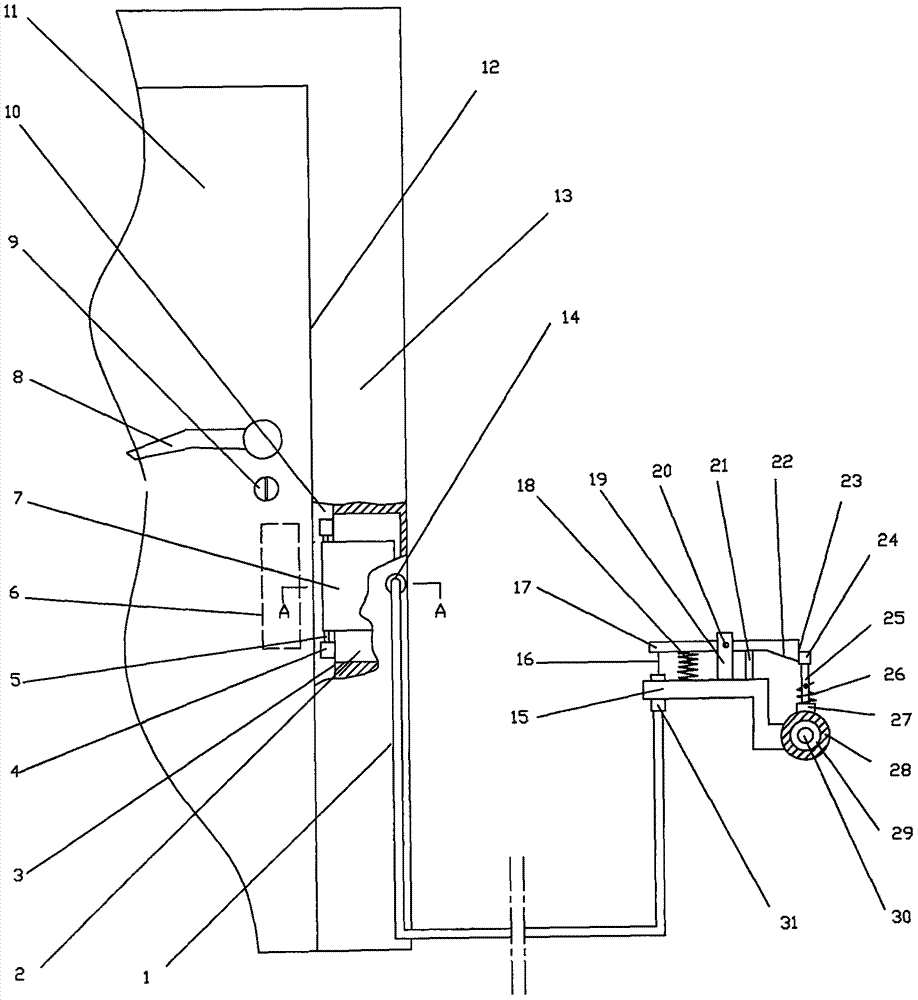

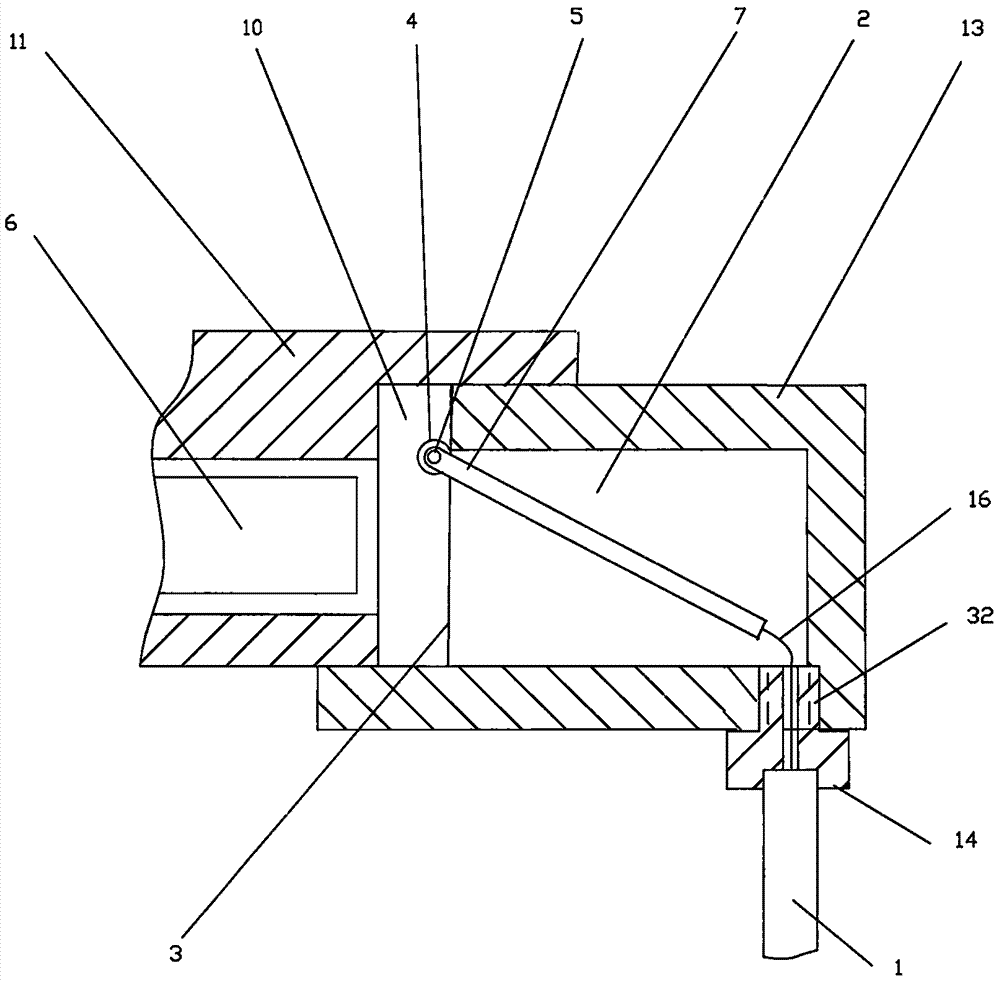

[0008] figure 1 It is a working principle diagram of the present invention. figure 1 Among them, 1 is the tension transmission wire sleeve pipe, 2 is the dead bolt frame, 3 is the inside of the door frame, and 4 is the axle sleeve as the dead bolt thrust lever fulcrum sleeve. 5 is the axle as dead bolt thrust lever fulcrum, and 6 is dead bolt, and 7 is the square sheet as dead bolt thrust lever arm, and 8 is handle. 9 is the key hole, 10 is the inner gap between the door and the frame, 11 is the door, 12 is the outer seam between the door and the frame, 13 is the door frame, 14 is the perforated screw fixed on the door frame, 15 is the base, 16 is the Tension transmission line, 17 is the end of the valve closing lever force arm, 18 is the compression spring under the valve close lever force arm, 19 is the bracket, 20 is the fulcrum shaft, 21 is the contact rod, and 22 is the resistance arm of the valve close lever 23 is the blocking surface, 24 is the handle, 25 is the handl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap