A method of improving casing rigidity

A technology of rigidity and width, applied in the field of improving the rigidity of the casing, can solve the problems of restricting the strengthening function, etc., and achieve the effects of improving the vibration characteristics, increasing the rigidity, and improving the coaxiality of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

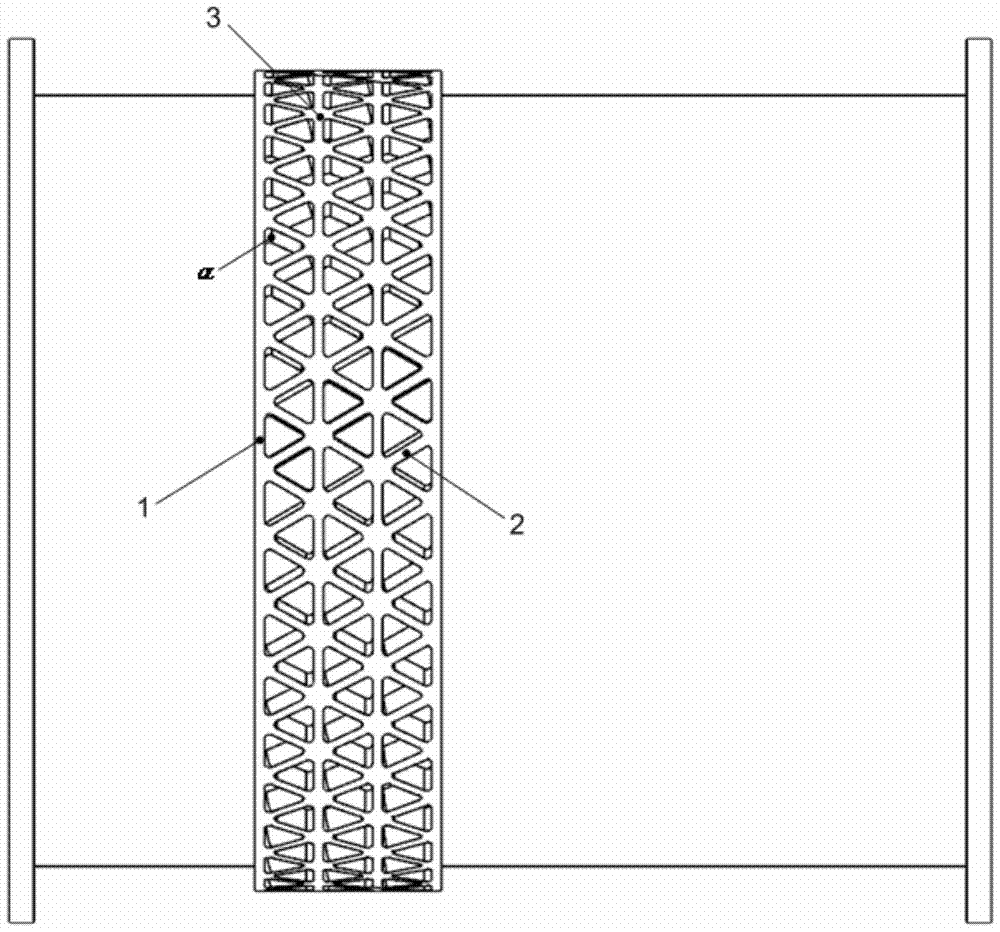

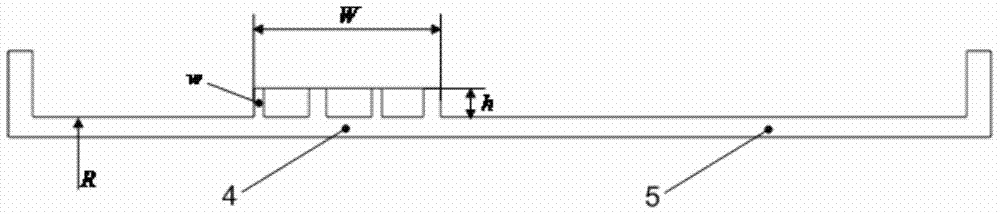

[0038] The invention provides a method for improving the rigidity of the casing, which is characterized in that: the method for improving the rigidity of the casing adopts an annular reinforcement rib 1, a spiral reinforcement rib 2, an equal grid reinforcement rib structure 3, a reinforcement area 4 and The combined structure of casing 5. According to the known shell radius R of the reinforced area, the corresponding design elements are determined according to Formula 1 within the initial width of the reinforced area, and then through the strength calculation and verification, four design elements are accurately selected to complete the casing with equal grid reinforcement Rigid design.

[0039] The reinforced area 4 with a width of W is a conical segment, and this method is applied to the conic surface projection;

[0040] The annular ribs 1 are equidistantly distributed along the engine axis in the reinforced area 4 with a width W.

[0041] A stable triangular reinforcing...

Embodiment 2

[0065]This embodiment provides a method for improving the rigidity of the casing, which is characterized in that: the method for improving the rigidity of the casing adopts ring ribs 1, spiral ribs 2, grid rib structures 3, and reinforced areas 4 Combined structure with casing 5. According to the known shell radius R of the reinforced area, the corresponding design elements are determined according to Formula 1 within the initial width of the reinforced area, and then through the strength calculation and verification, four design elements are accurately selected to complete the casing with equal grid reinforcement Rigid design.

[0066] The reinforced area 4 with a width W is a cylindrical segment;

[0067] The annular ribs 1 are equidistantly distributed along the engine axis in the reinforced area 4 with a width W.

[0068] A stable triangular reinforcing structure is formed between two adjacent annular reinforcing ribs 1 by a spiral reinforcing rib 2, the triangle must be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com