Indoor space adjusting wall based on 3D module splicing

A wall and 3D technology, applied to walls, building components, buildings, etc., can solve the problems of easy pollution and time-consuming, and achieve the effects of good stability, easy operation, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

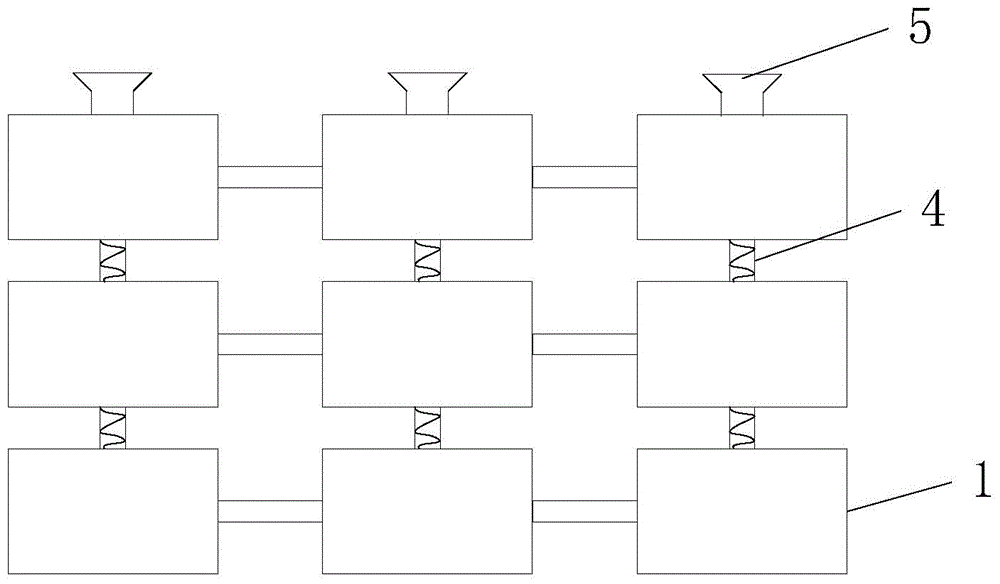

[0014] Specific implementation method: When using, it is necessary to check whether the hinge can be used normally and whether the sub-wall is damaged. If there is a defect in the inspection, it cannot be used. If everything is normal, it can be used. When using the nine sub-walls Take it to the construction site for splicing. Insert the connecting columns on the left and right ends of the sub-walls into the fixing cavity to ensure that the connecting columns will not fall off. The nine sub-walls are spliced into three rows, and the three rows of sub-walls are connected by bolts and hinges. The upper and lower sides are connected together in turn, and the sub-wall with the suction cup is placed on the top. After the wall is spliced, the suction cup is used to fix the wall on the beam. When the space of the house needs to be increased, the bottom sub-wall The hinge is used to fold up and fix it, which increases the space of the house and makes two spaces into one space. It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com