Monorail crane heavy walking trolley

A walking trolley and heavy lifting technology, which is applied in the direction of walking mechanism, load hanging components, transportation and packaging, etc., can solve the problems of not being able to bear all the gravity of the goods, no change in the carrying capacity, and inconvenient use, etc., to solve the problem of load wear problems, enhanced load-bearing capacity, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

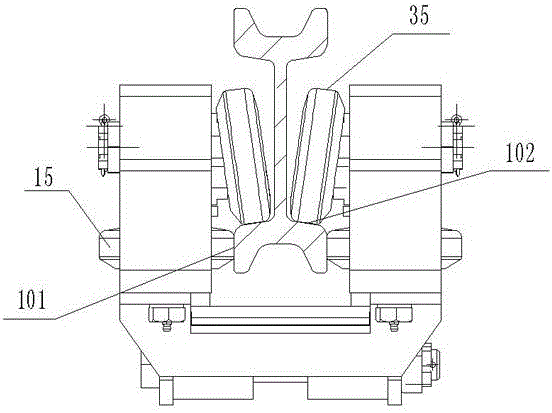

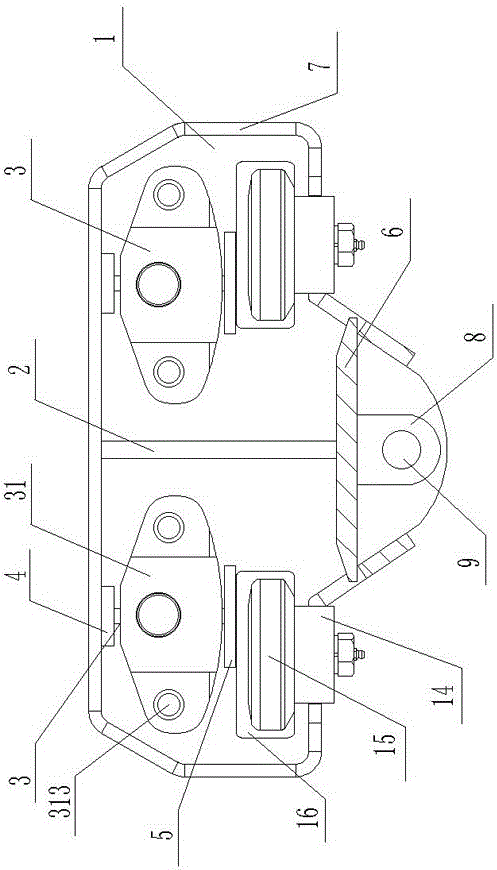

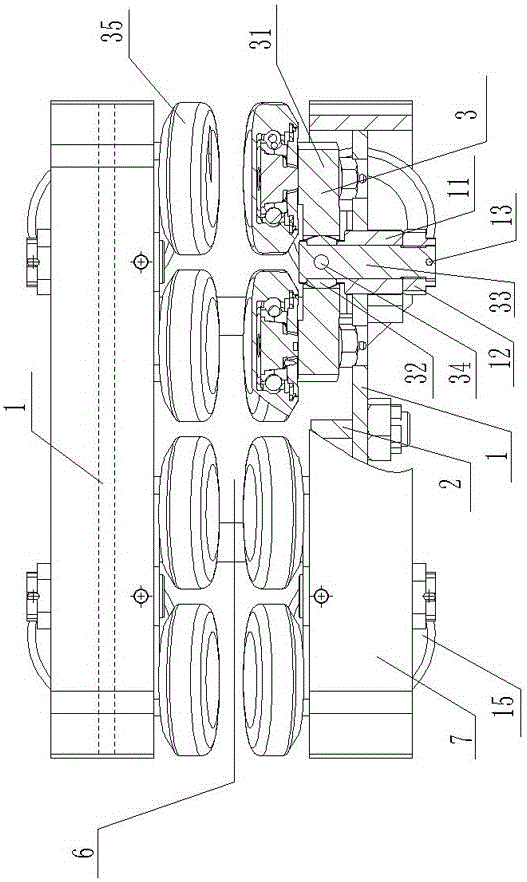

[0025] Such as figure 1 with figure 2 As shown, the present invention provides a monorail hoisting heavy-duty walking trolley, which includes two main frame plates 1 arranged in parallel. Each main frame plate 1 is fixedly connected with a reinforcing rib 2 along the vertical direction. The two main frame plates 1 pass through The supporting plates 6 at the bottom of the reinforcing ribs 2 are connected together. Wherein, the main frame plate 1 is provided with a wheel guide device 3 and an axle seat 14 located below the wheel guide device on both sides of the reinforcing rib 2. The axle seat 14 is used to install a guide wheel 15 in the axial direction along the vertical direction. The wheel body of 15 is arranged in the guide wheel hole 16 above the shaft seat 14; each wheel guide device 3 includes a seesaw 31, a spherical sleeve 32 arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com