Rapid prototyping apparatus for page width jet printing

A molding device and page width technology, applied in the field of rapid prototyping devices, can solve the problems of 3D solid model volume limitation and slow molding speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the present invention can have various changes in different aspects, all of which do not depart from the scope of the present invention, and the descriptions and illustrations therein are used as illustrations in nature rather than limiting the present invention .

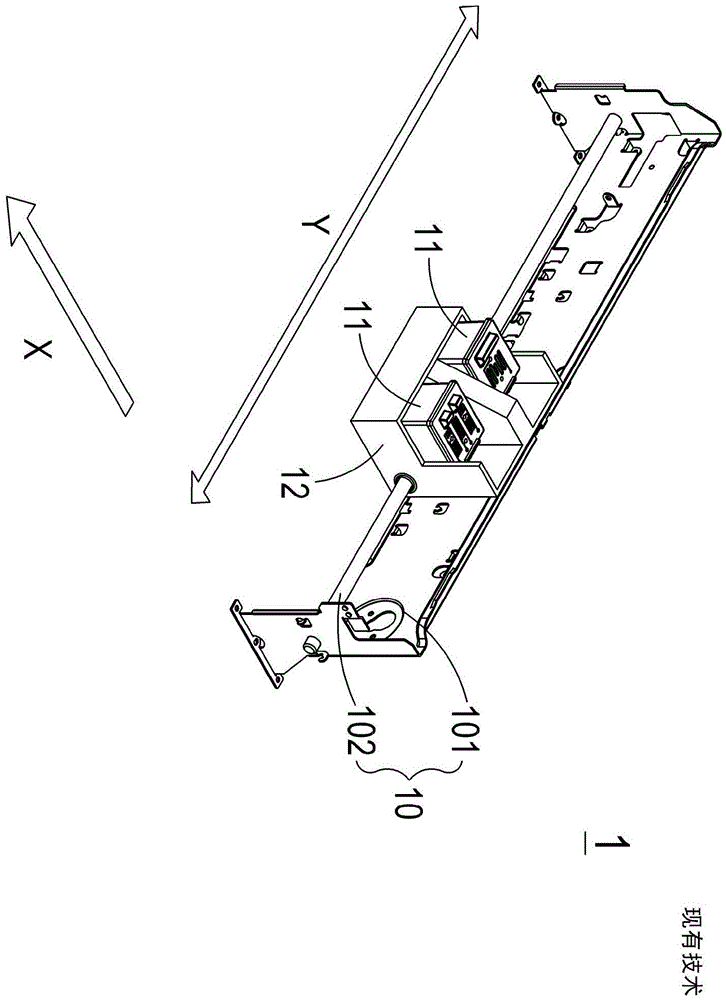

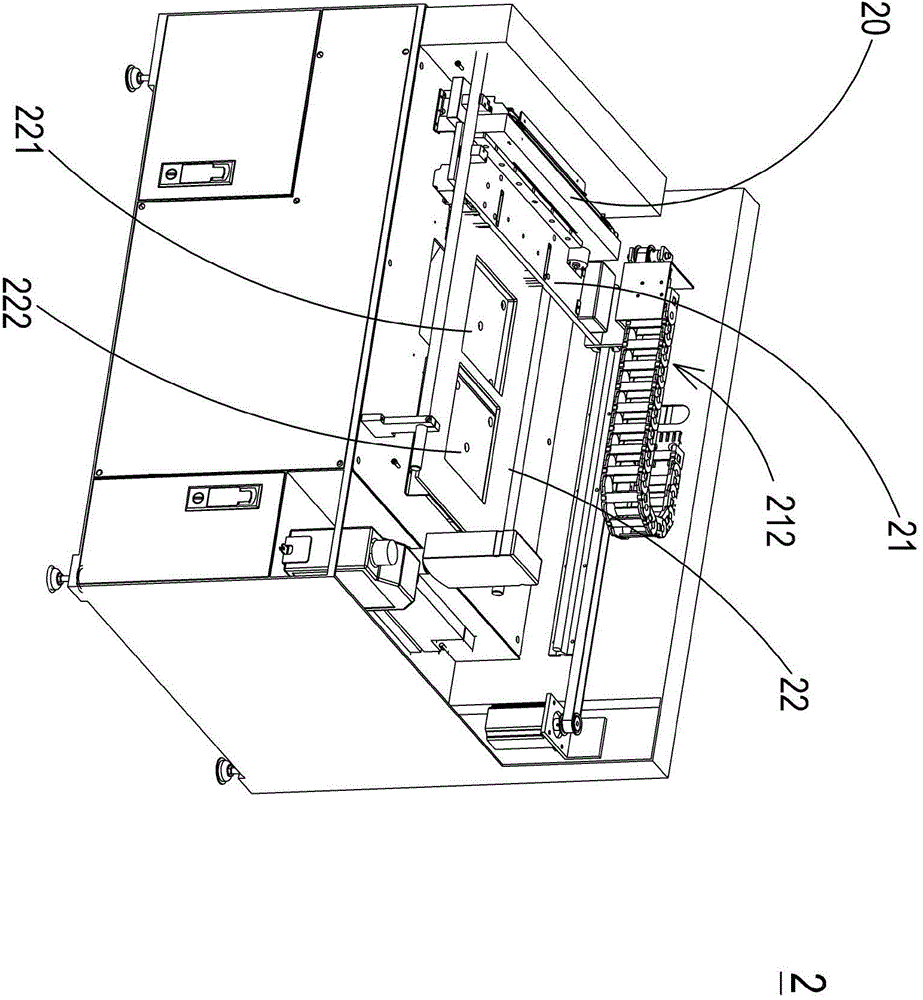

[0051] The present invention provides a rapid prototyping device for page-wide jet printing. Of course, the page-wide jet printing is implemented by using a page-wide jet printing module. Compared with the known general scanning and reciprocating jet printing technology, it does not require scanning and reciprocating Movement to implement printing, that is, as figure 1 In the scanning reciprocating motion in the Y direction shown, multiple inkjet heads with the page width printing size set on the page width printing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com