An up-tilt three-way rigid contact hole sensor installation and recovery device

A recovery device and sensor technology, applied to seismic signal receivers, etc., can solve problems such as sensor damage, waste, and impact on monitoring effects, and achieve the effects of improving data collection capabilities, simple and convenient operation, and improving data reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

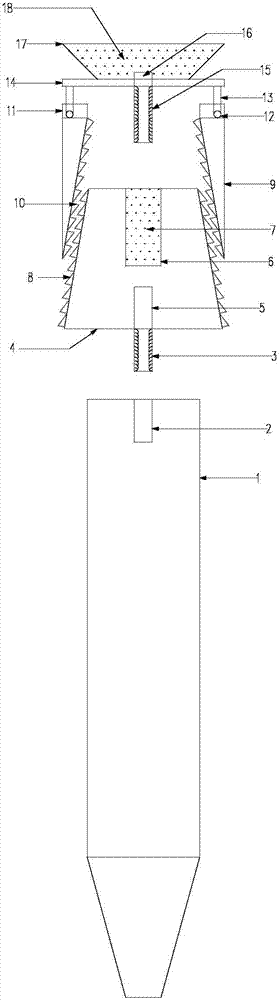

[0030] An upward-inclining three-way rigid contact hole sensor installation and recovery device, including a sensor 1 and a docking case 4, the bottom of the docking case 4 is detachably connected to the sensor 1, and the top of the docking case 4 is provided with Epoxy resin fixing hole 6, epoxy resin colloid 7 is arranged in the epoxy resin fixing hole 6, also includes tray 14, cup 17 is fixed on the tray 14, concrete or epoxy resin 18 is set in the cup 17, set on the tray 14 There is a second threaded rod 15 for insertion into the epoxy glue 7 .

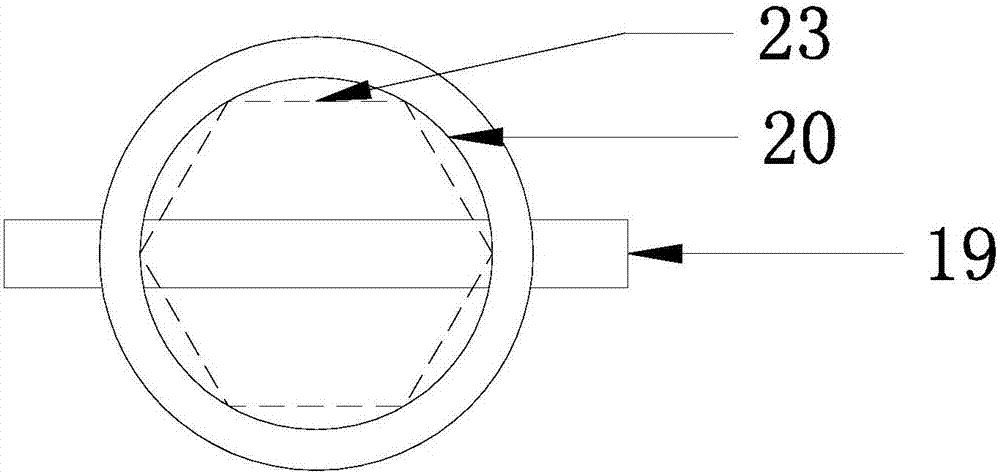

[0031] An upward-inclining three-way rigid contact hole mounted sensor installation and recovery device also includes an extrusion clamping part 9, and a steel ball guide groove 11 is opened on the top of the extrusion clamping part 9, and a ball guide groove 11 is embedded in the steel ball g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com